Wet friction material

A friction part, wet technology, applied in the direction of friction linings, friction clutches, clutches, etc., can solve the problems of ATF being difficult to be discharged, the total area of the oil passage is limited, etc., and achieve the effect of high drag torque reduction effect and large reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

First, refer to Figure 1 to Figure 5 The wet friction material according to Embodiment 1 of the present invention will be described.

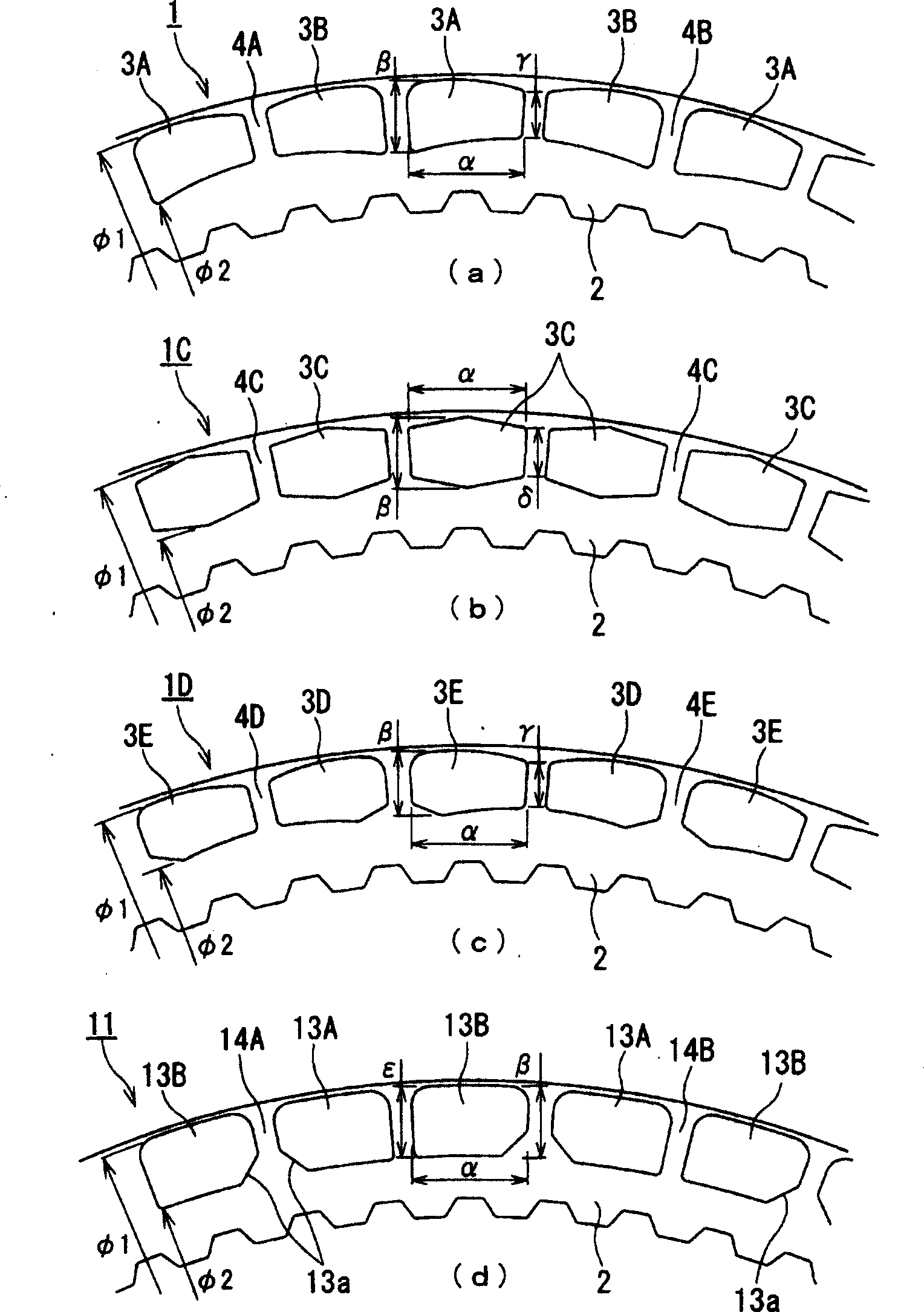

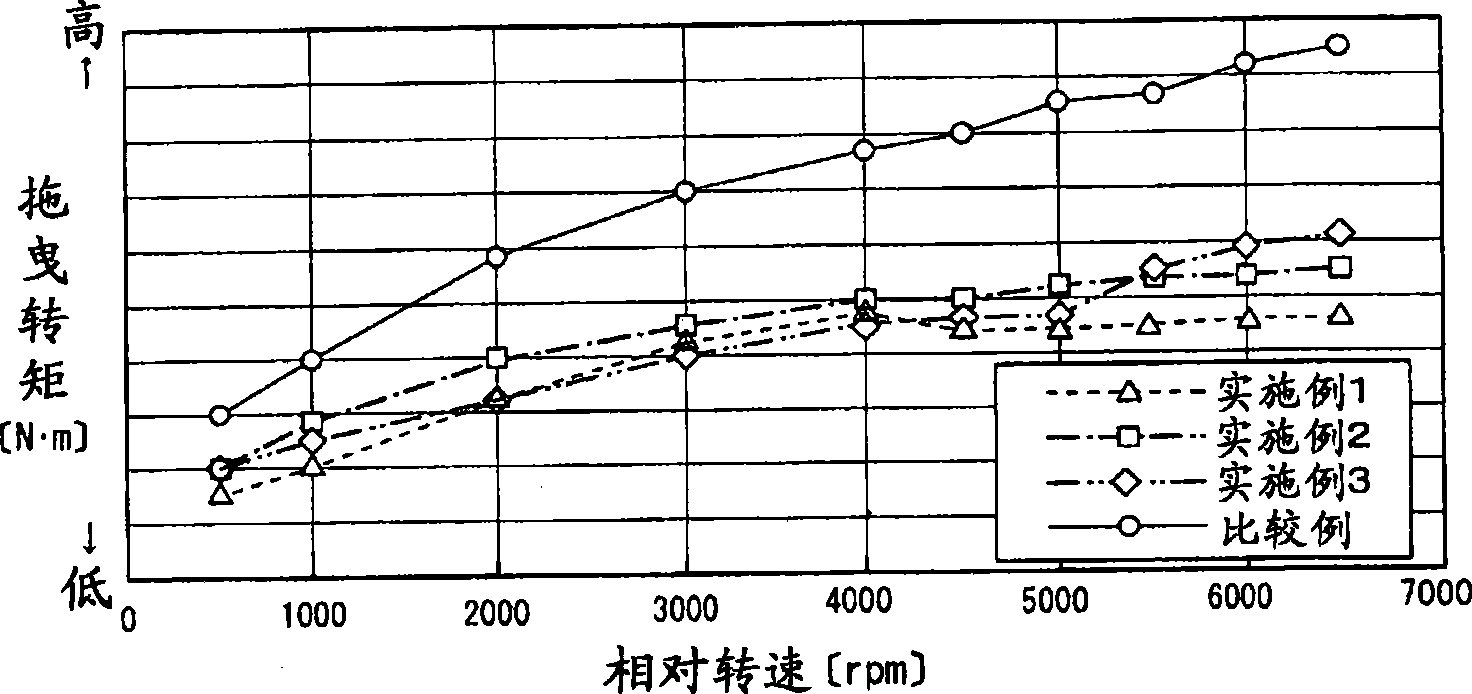

[0044] figure 1 (a) is a partial plan view showing a part of a wet friction material (Example 1) according to Embodiment 1 of the present invention, and (b) is a wet friction material (Example 2) showing a first modified example of Embodiment 1 of the present invention. ), (c) is a partial plan view showing a part of a wet friction material (Example 3) according to a second modified example of Embodiment 1 of the present invention, and (d) is a wet friction material showing a prior art Partial plan view of a part of (Comparative Example).

[0045] figure 2(a) is a partial plan view showing a part of a wet friction material according to a third modified example of Embodiment 1 of the present invention, and (b) is a partial plan view showing a part of a wet friction material according to a fourth modified example of Embodiment 1 of the presen...

Embodiment approach 2

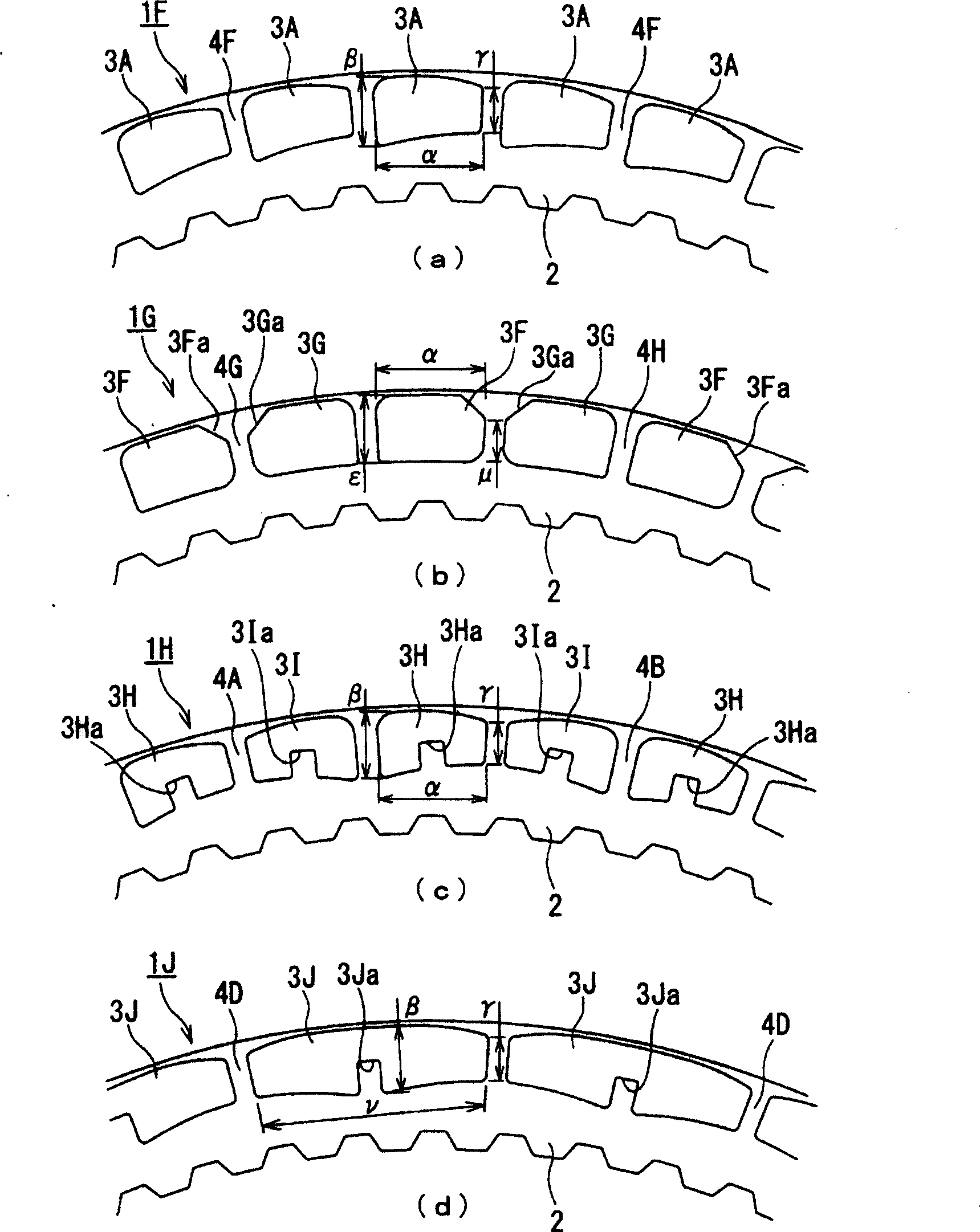

Refer below Image 6 and Figure 7 , the wet friction material according to Embodiment 2 of the present invention will be described. Image 6 (a) is a partial plan view showing a part of the wet friction material according to Embodiment 2 of the present invention, (b) is a partial cross-sectional view showing a vertical section of the wet friction material according to Embodiment 2 of the present invention, and (c) is a partial sectional view showing the present invention. (d) is a partial plan view showing a part of a wet friction material according to a second modification of Embodiment 2 of the present invention.

[0107] Figure 7 (a) is a partial plan view showing a part of a wet friction material according to a third modified example of Embodiment 2 of the present invention, and (b) is a partial plan view showing a part of a wet friction material according to a fourth modified example of Embodiment 2 of the present invention Plan view, (c) is a partial plan view showin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com