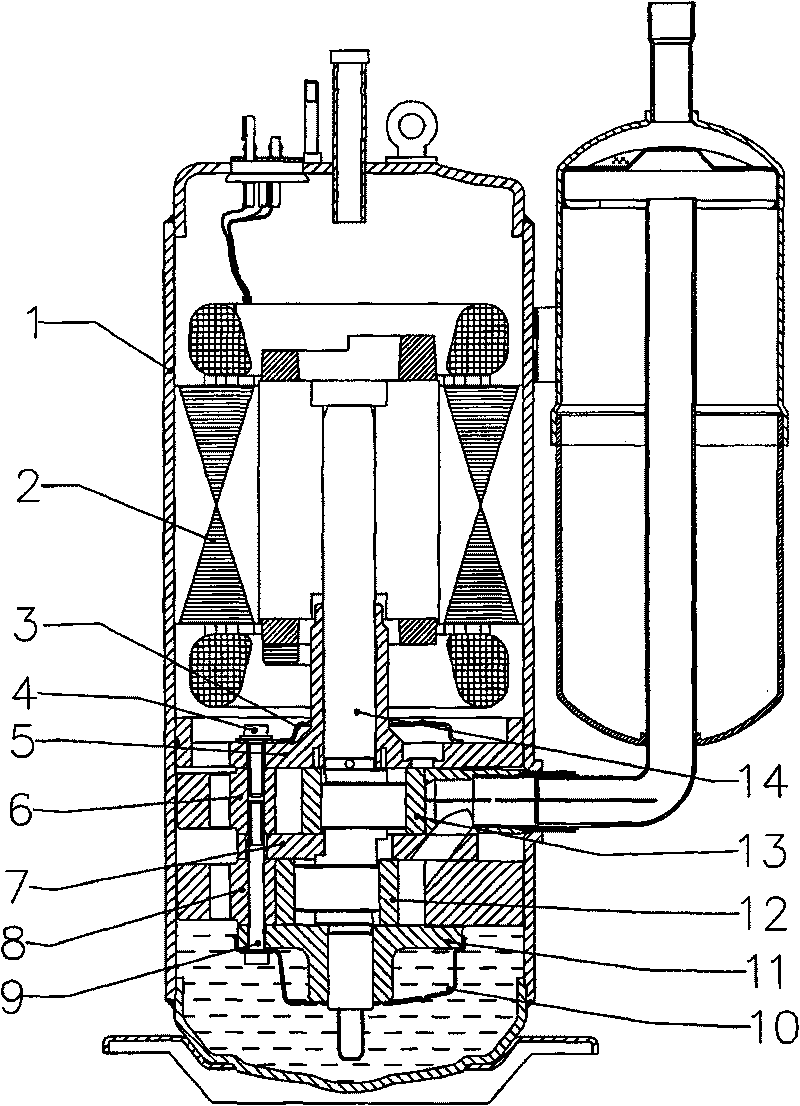

Assembling method of rotary double cylinder compressor pump body

A double-cylinder compressor and assembly method technology, which is applied in the field of compressors, can solve the problems of small inclination distance, affecting the cooling capacity and quality of the compressor, and the inability to ensure the minimum leakage of refrigerant, so as to reduce leakage and increase cooling capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

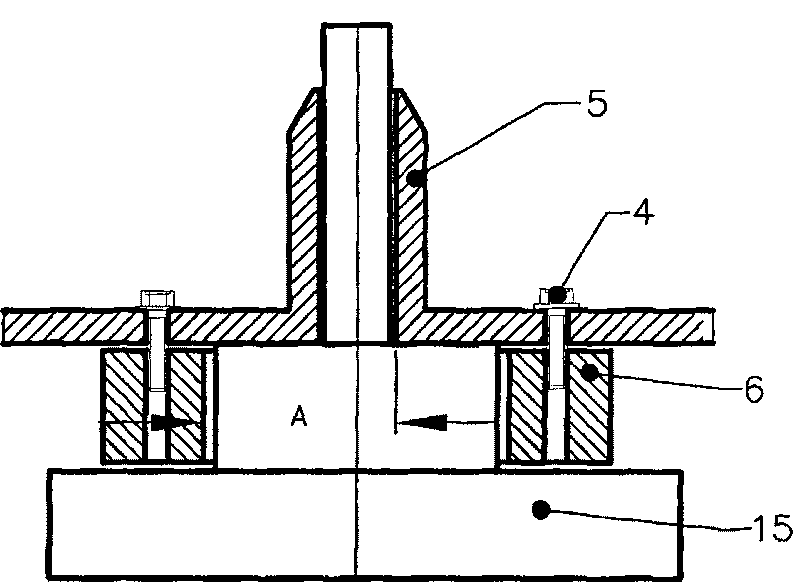

Embodiment Construction

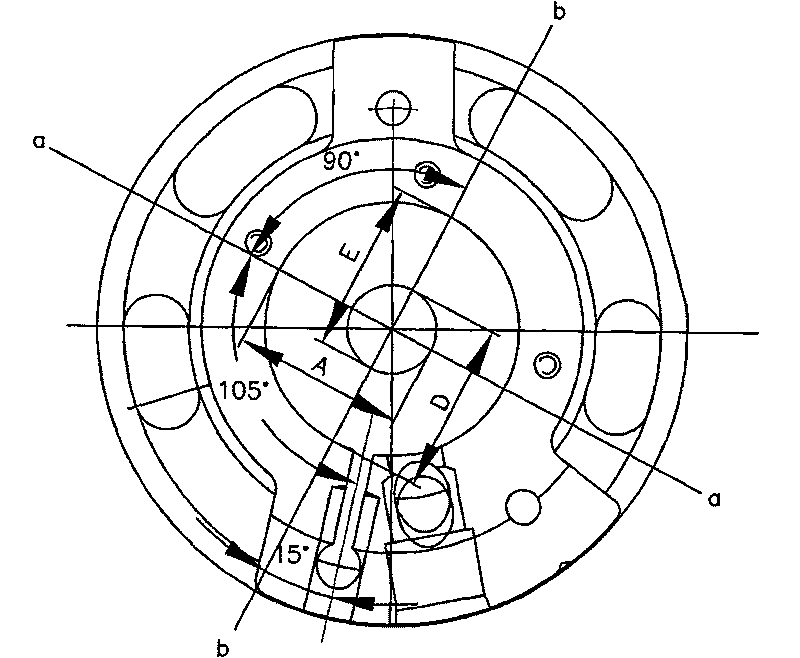

[0037] Before the actual assembly, the reference data necessary for assembly must first be obtained through measurement. Such as Figure 5 As shown, it includes measuring the maximum distance Amax between the upper roller 13 placed on the eccentric circle of the crankshaft 14 and the maximum outer circular track of the crankshaft major axis, and the maximum distance Amax between the lower roller 12 placed on the eccentric circle of the crankshaft 14 and the major axis of the crankshaft. The maximum distance Bmax between the outer circular orbits, and the maximum distance Cmax between the lower roller 13 placed on the eccentric circle of the crankshaft 14 and the maximum outer circular orbit of the short axis of the crankshaft. During the measurement process, press the long axis of the crankshaft with your hand to make the long axis of the crankshaft fully contact with the measuring bracket, and then turn the crankshaft to find the maximum Amax, Bmax and Cmax. When the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com