Design proposal for grinding copper holder locking notch and clamping device

A design method and clamping device technology, applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., to achieve the effect of high precision, small size, and stable clamping device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

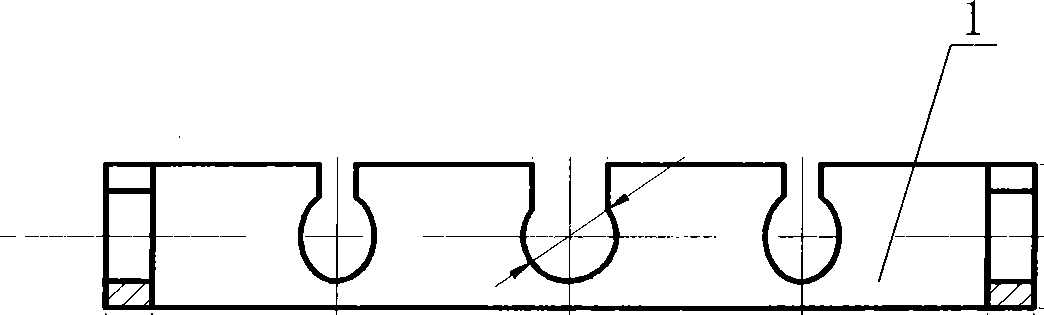

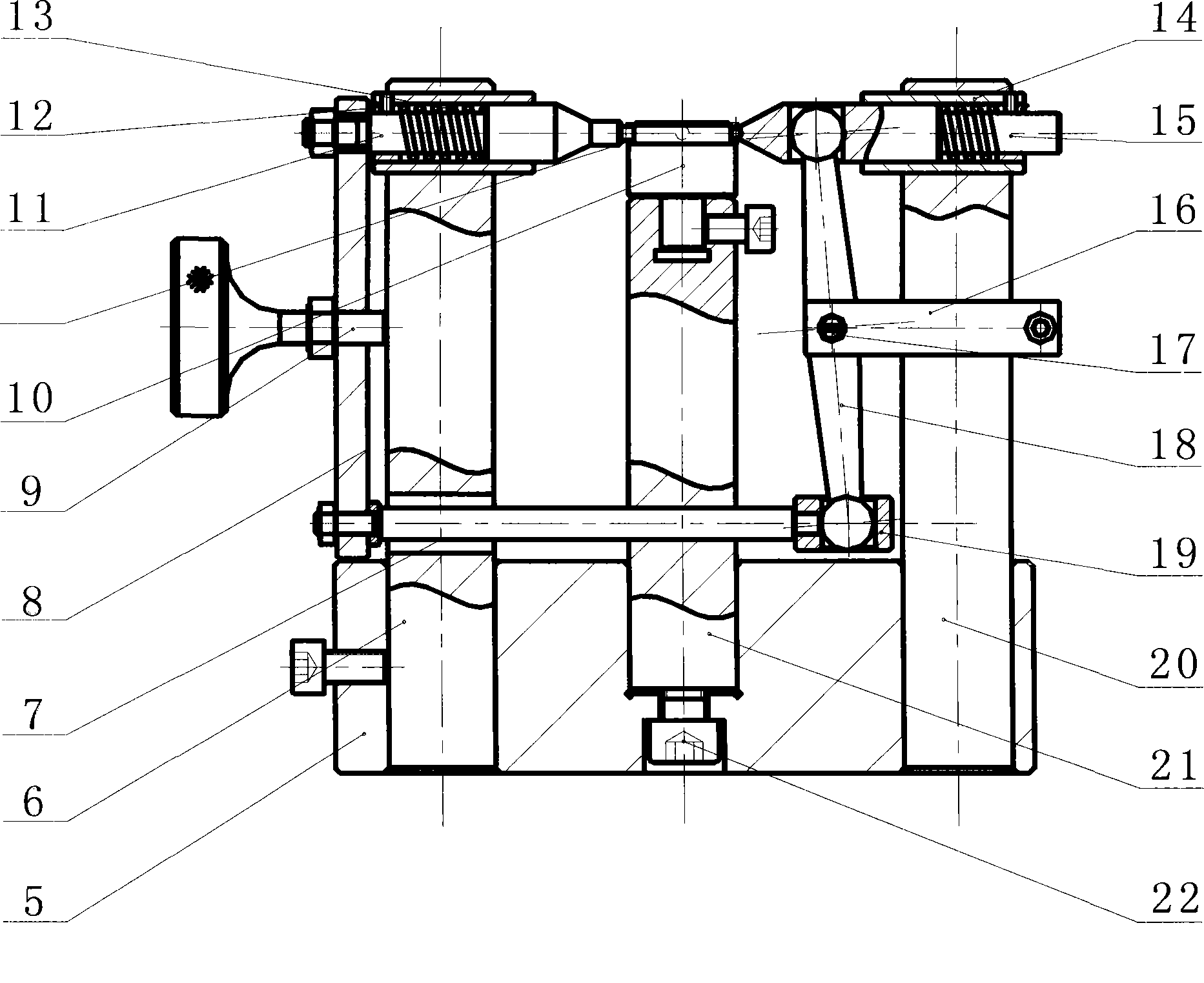

[0018] The design method of the grinding and processing copper cage lock of the present invention mainly includes the following contents:

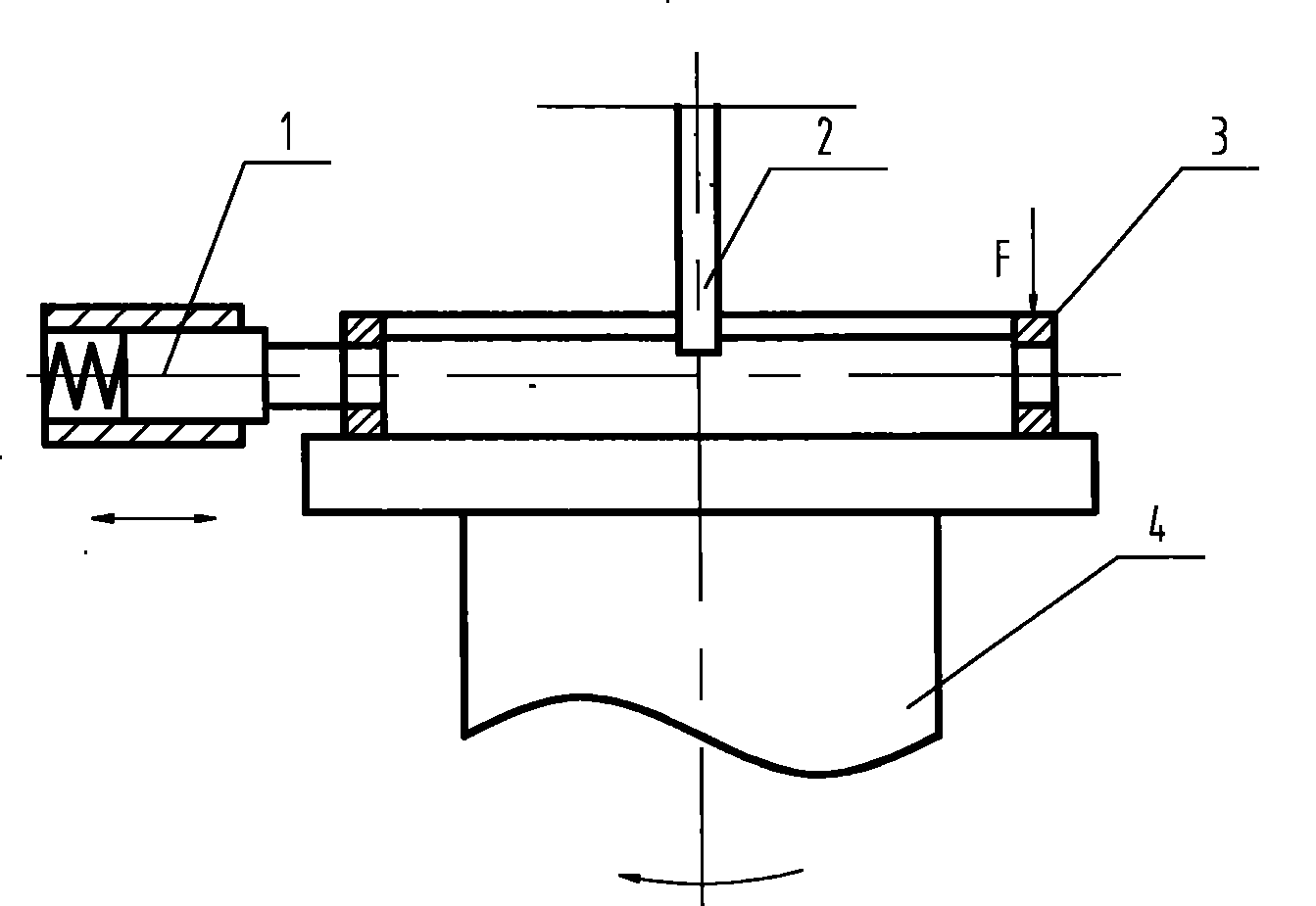

[0019] 1) Design two positioning pins that can move left and right respectively to clamp the cage to be processed. The axial clamping force of the positioning pin comes from the compression spring, and the axes of the two positioning pins should be concentric;

[0020] 2) The cage to be processed is placed on the positioning mandrel, and the positioning mandrel is required to be adjusted up and down;

[0021] 3) Pulling the left and right positioning pins must be a simultaneous linkage process, which can only be performed by one linkage mechanism;

[0022] 4) The whole device should be compact in structure, balanced in clamping force and able to pull the left and right positioning pins outward or clamp inward at the same time, so as to achieve the purpose of safely pressing or picking and placing the cage to be processed.

[0023] combine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com