Container after-frame assembling tyre and assembling method

A container, rear frame technology, used in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

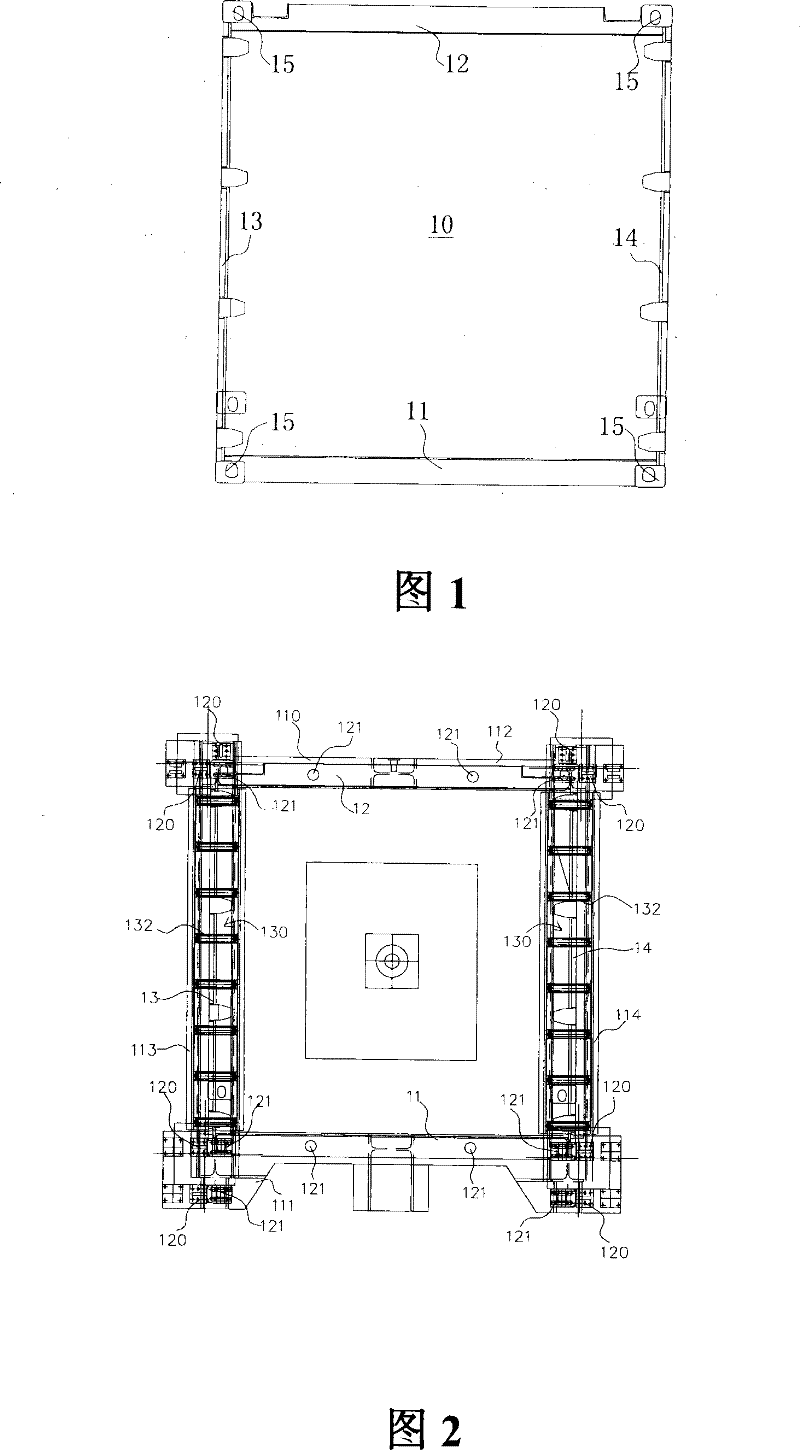

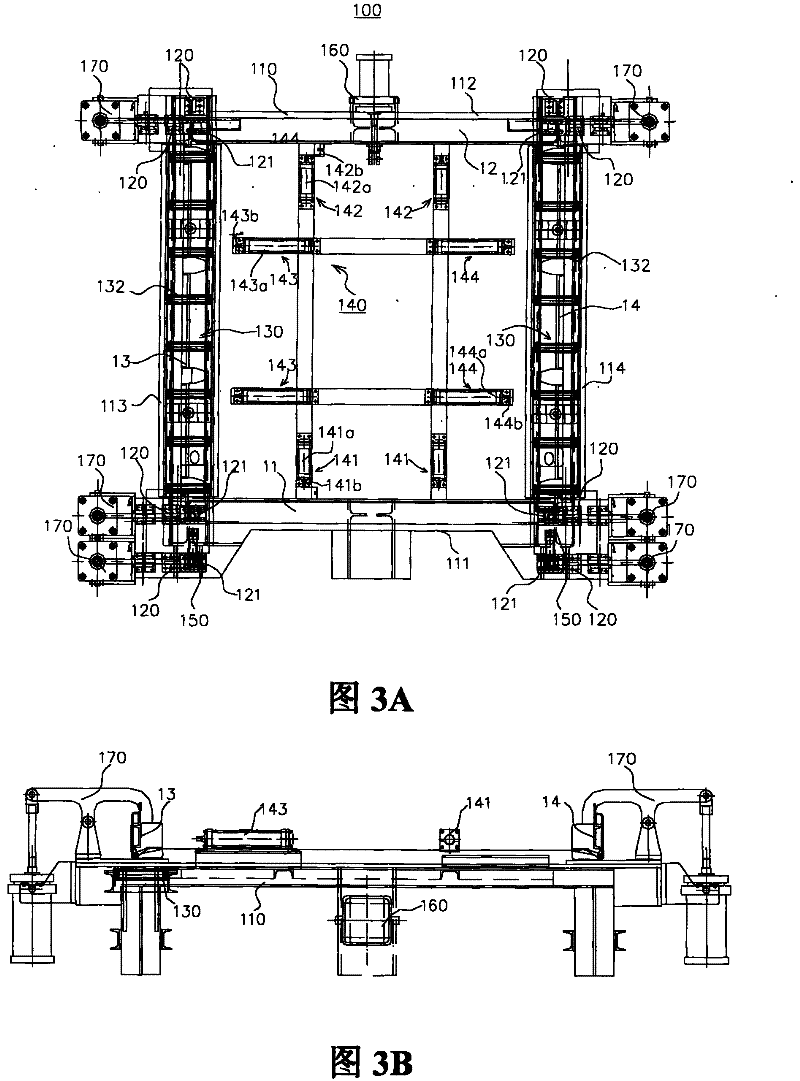

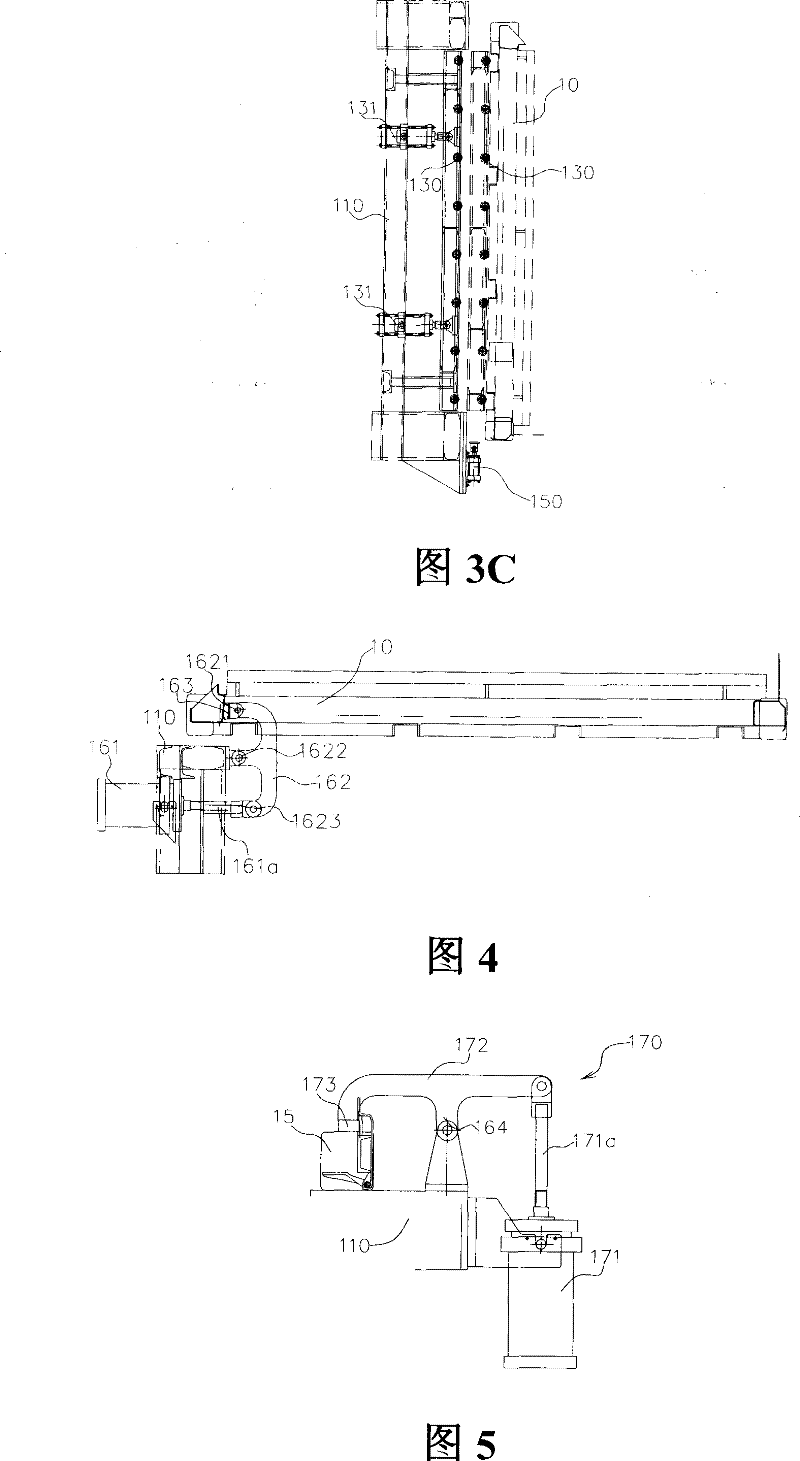

[0033] The rear frame assembly tire of the present invention will be described below with reference to the accompanying drawings.

[0034] like Figures 3A to 3C As shown, the rear frame assembling tire 100 of the present invention includes an in-frame positioning device 140 in addition to the previously described chassis 110 , a plurality of horizontal positioning blocks 120 , a plurality of vertical positioning blocks 121 and a roller passing device 130 . refer to Figure 3A , 3B , the frame positioning device 140 is arranged in the middle part of the bottom frame 110, and is surrounded by the end beam and the side beam of the bottom frame. The in-frame positioning device 140 includes four groups of pressing devices 141 , 142 , 143 and 144 , which are respectively disposed corresponding to the two end beams and the two side beams of the bottom frame 110 . Preferably, each set of pressing devices may include two pressing devices arranged in parallel. The main bodies 141a,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com