Manufacturing method for flexible bus

A manufacturing method and technology for flexible wiring, which are used in cable/conductor manufacturing, electrical connection of printed components, printed circuit components, etc., can solve problems such as characteristic impedance specification deviation, and achieve the effect of small dimensional tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a deeper understanding of the technical means and effects adopted to achieve the creation of the present invention, it will be described in detail below in conjunction with the accompanying drawings, so as to thoroughly analyze the purpose, realization methods and special effects of the present invention. However, the following drawings are for reference only, and are not intended to limit the protection scope of the present invention.

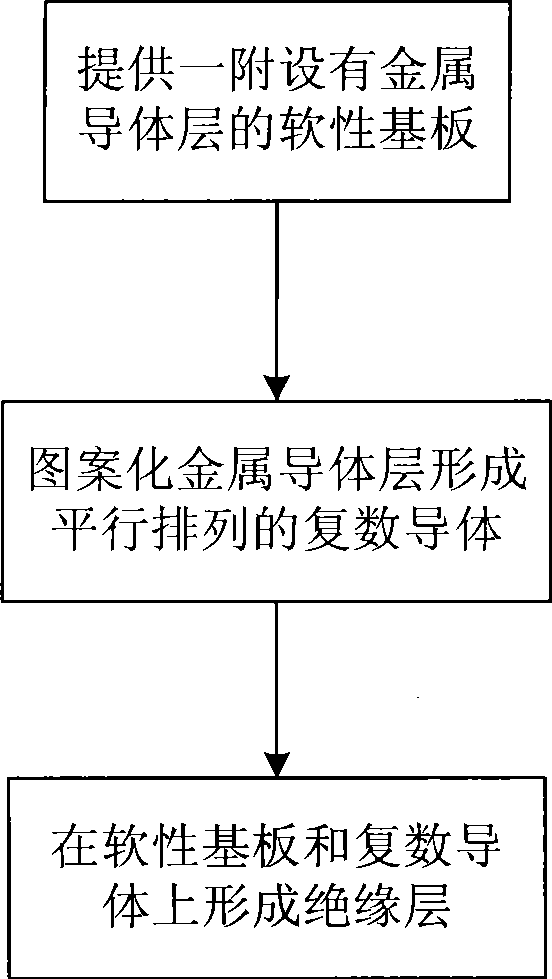

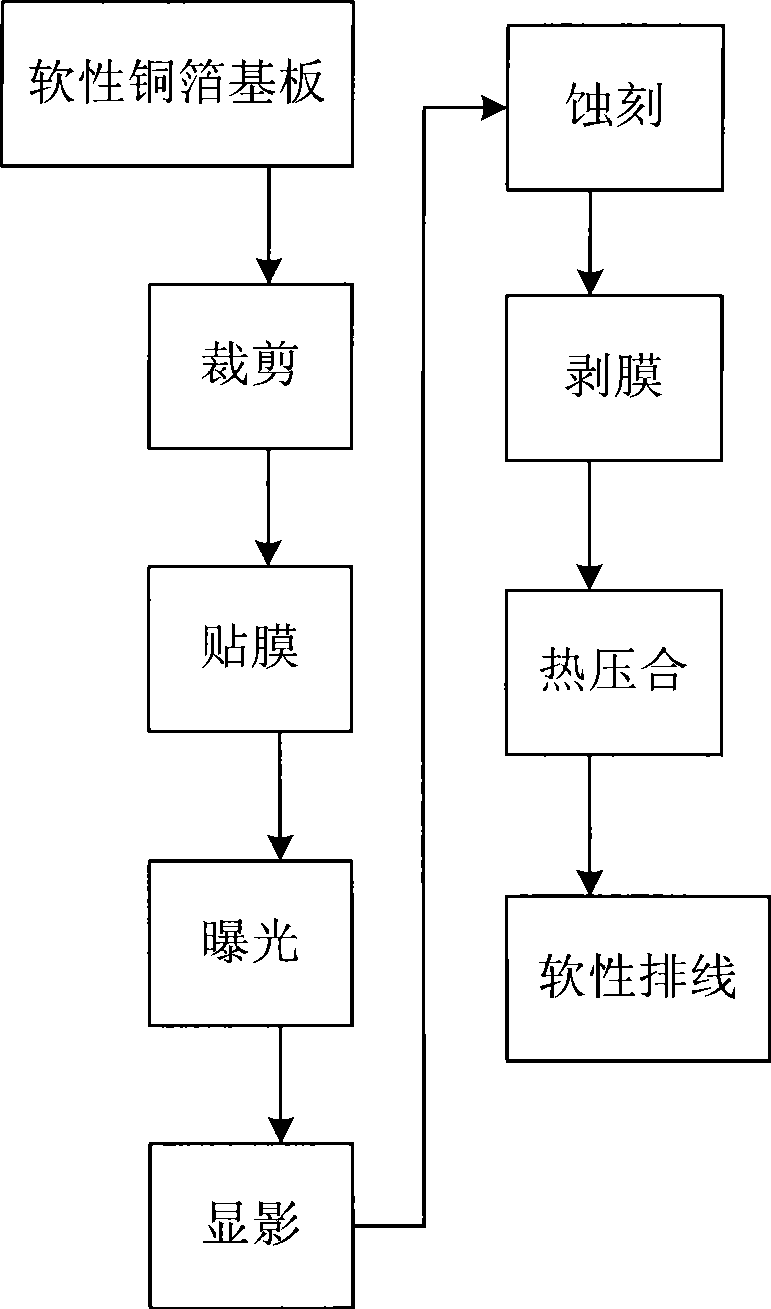

[0018] Such as figure 1 Shown is a schematic flow chart of the main steps of the manufacturing method of the flexible cable of the present invention. The steps are as follows: first provide a flexible substrate, and set a metal conductor layer on it; then pattern the metal conductor layer to form a plurality of metal conductors arranged in parallel; then form an insulating layer on the flexible substrate On, the insulation layer covers the plurality of metal conductors 30 . In this embodiment, the flexible substrate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com