Guide electromagnetic valve with hand push button

A pilot-operated solenoid valve and pilot-operated valve technology, which is applied to flushing equipment with water tanks, valve devices, valve details, etc., can solve the problems of solenoid valve failure, no filter, and many consumables, so as to save materials and prevent The effect of long service life and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

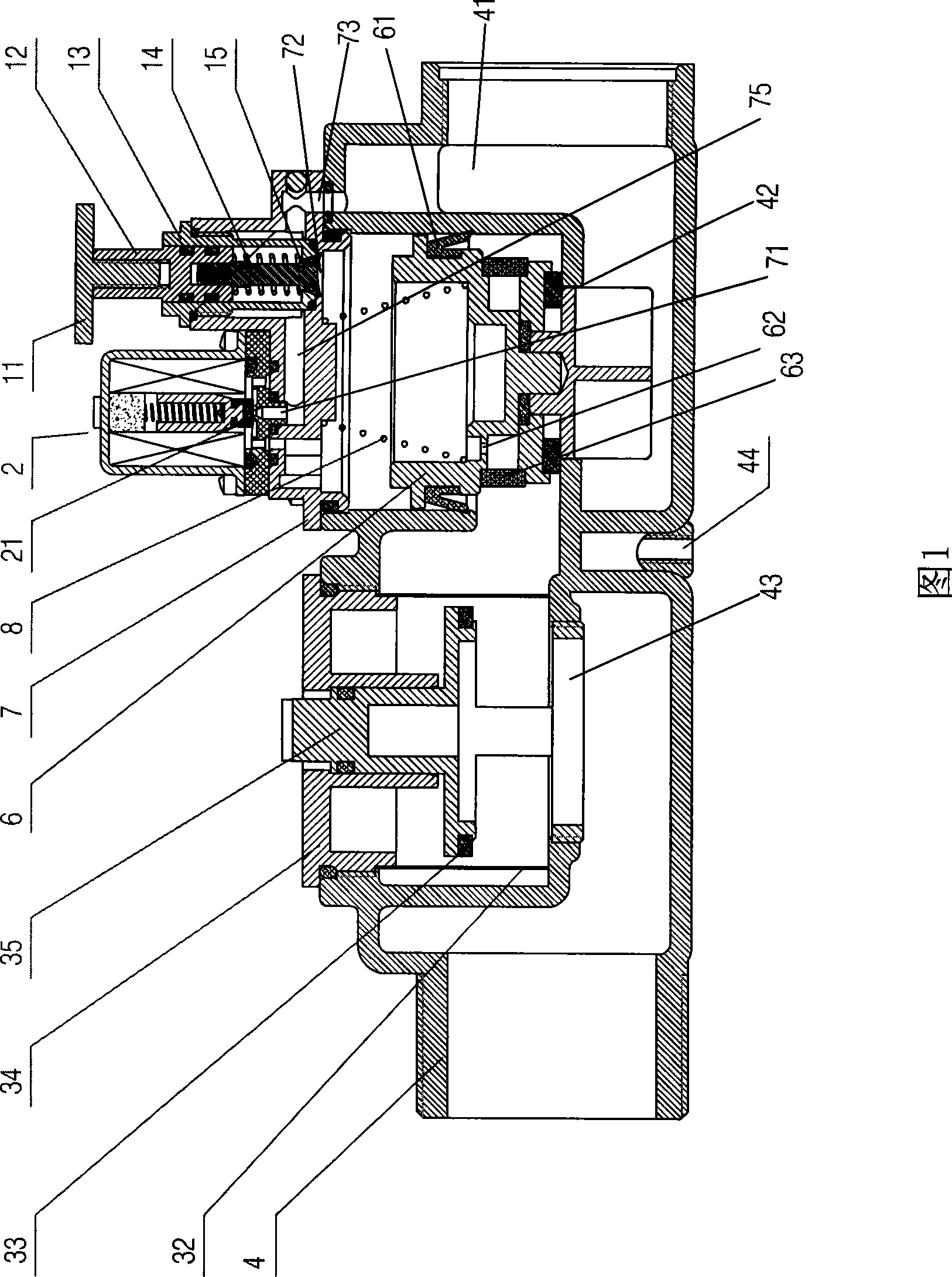

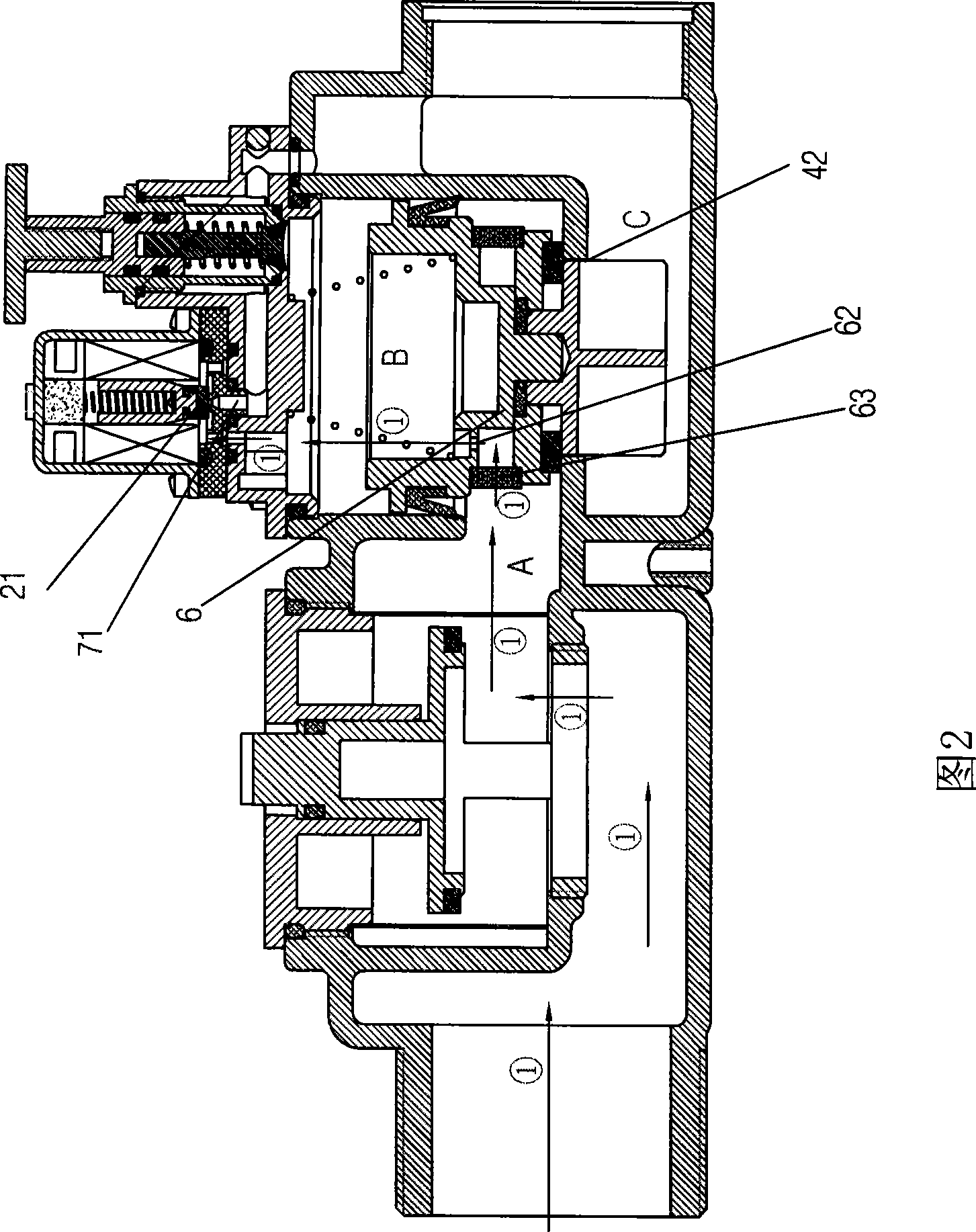

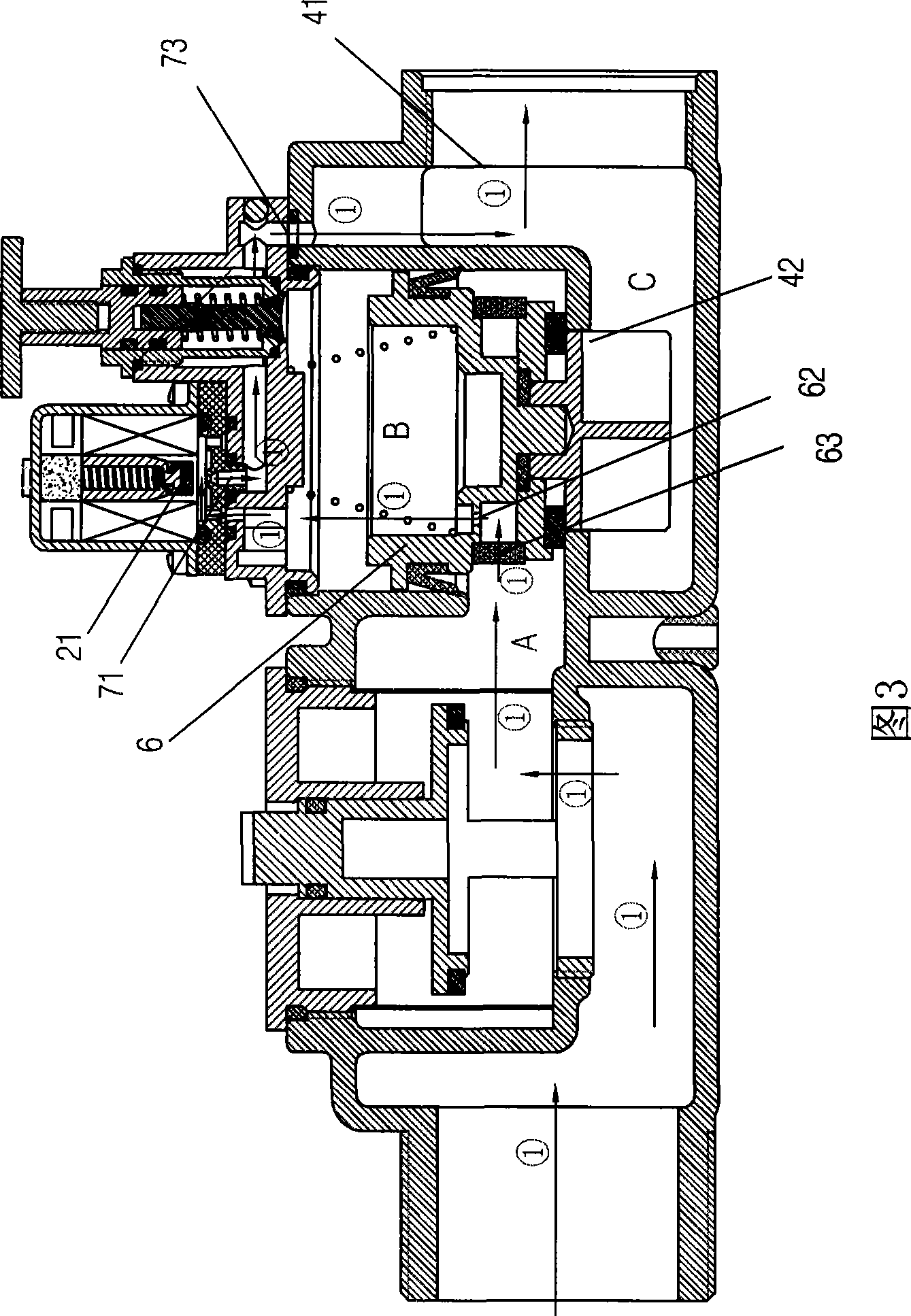

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] As shown in Figure 1 and Figure 6, the pilot solenoid valve with manual button includes the main valve body 4, the cut-off filter valve assembly 3, the movable spool assembly 6, the return spring 8, the pilot valve body 7, the solenoid valve assembly 2 and The manual valve assembly 1, the cut-off filter valve assembly 3 is arranged on the front passage in the main valve body 4, the rear passage in the main valve body 4 is divided into upper and lower two passages, the entrance of the upper passage is provided with a movable spool assembly 6 with a small hole 62, and the upper passage The outlet valve body is connected to the pilot valve body 7, and a sealed cavity is formed between the movable valve core assembly 6 and the pilot valve body 7, and one end of the return spring 8 is supported on the pilot valve body 7, and the other end is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com