Solvent thermal synthesizing method of lead fluoride hollow nano sphere

A synthesis method and nanosphere technology, applied in the direction of lead halide, etc., to achieve the effect of safe operation, controllable size and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

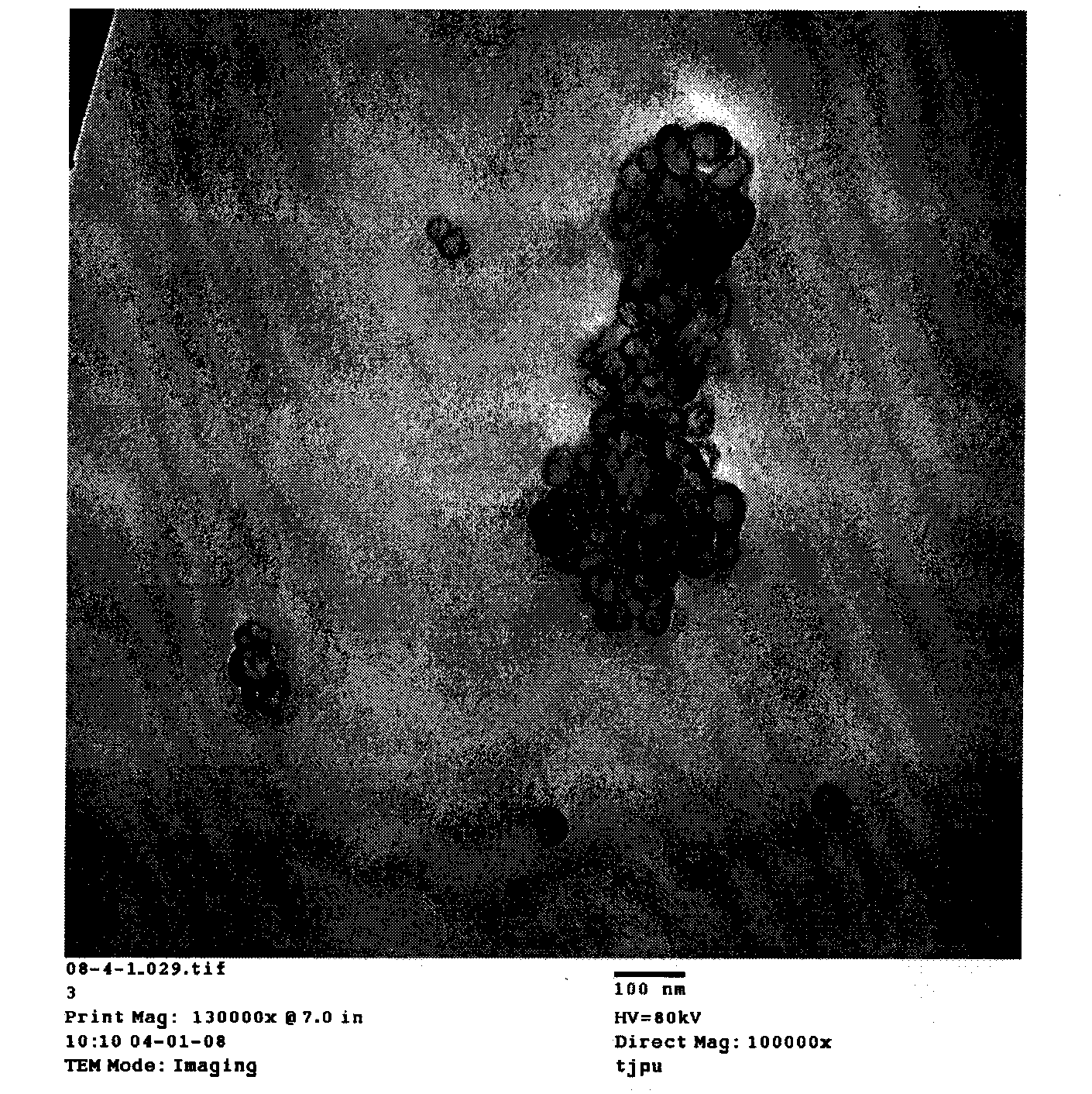

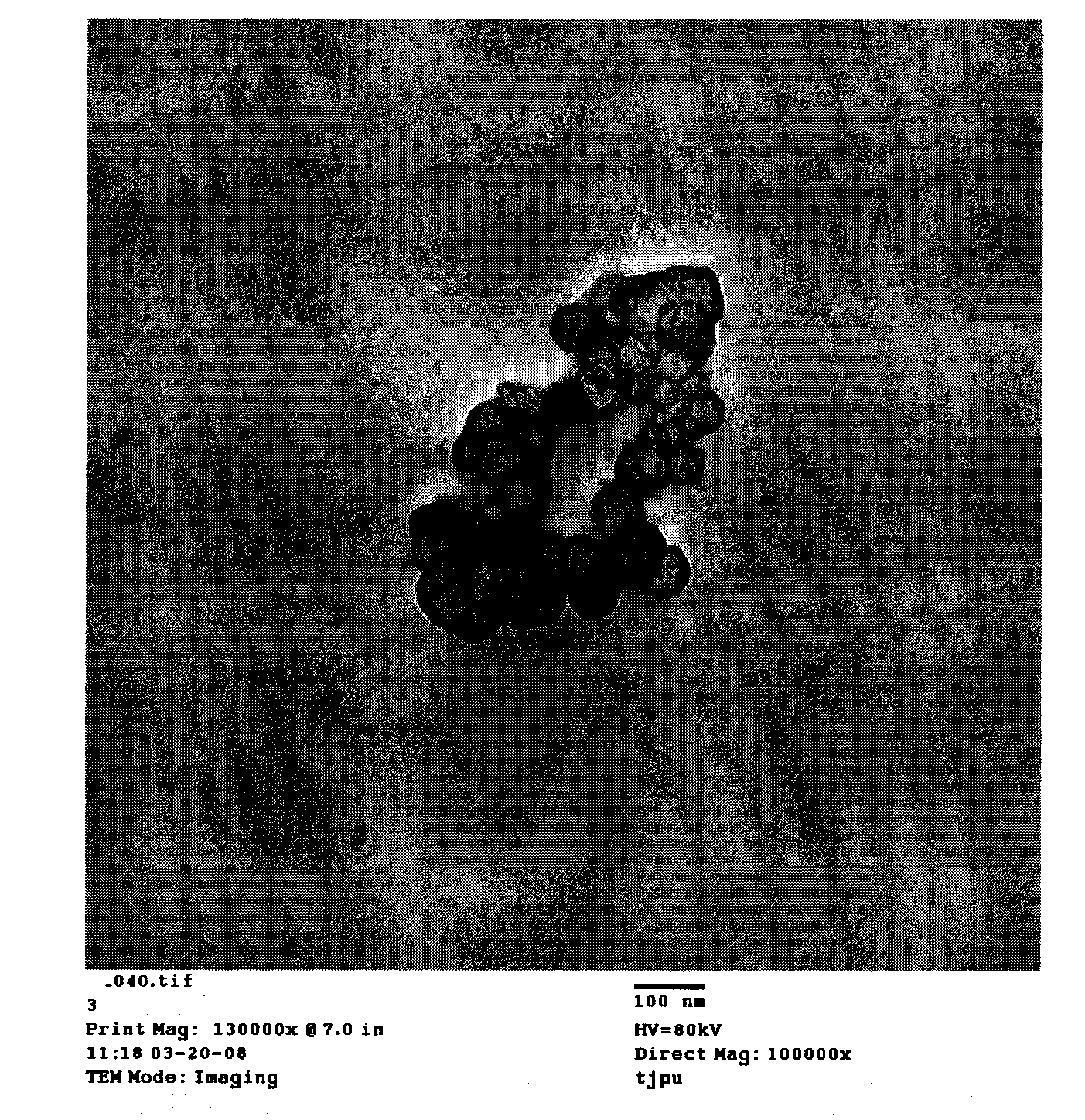

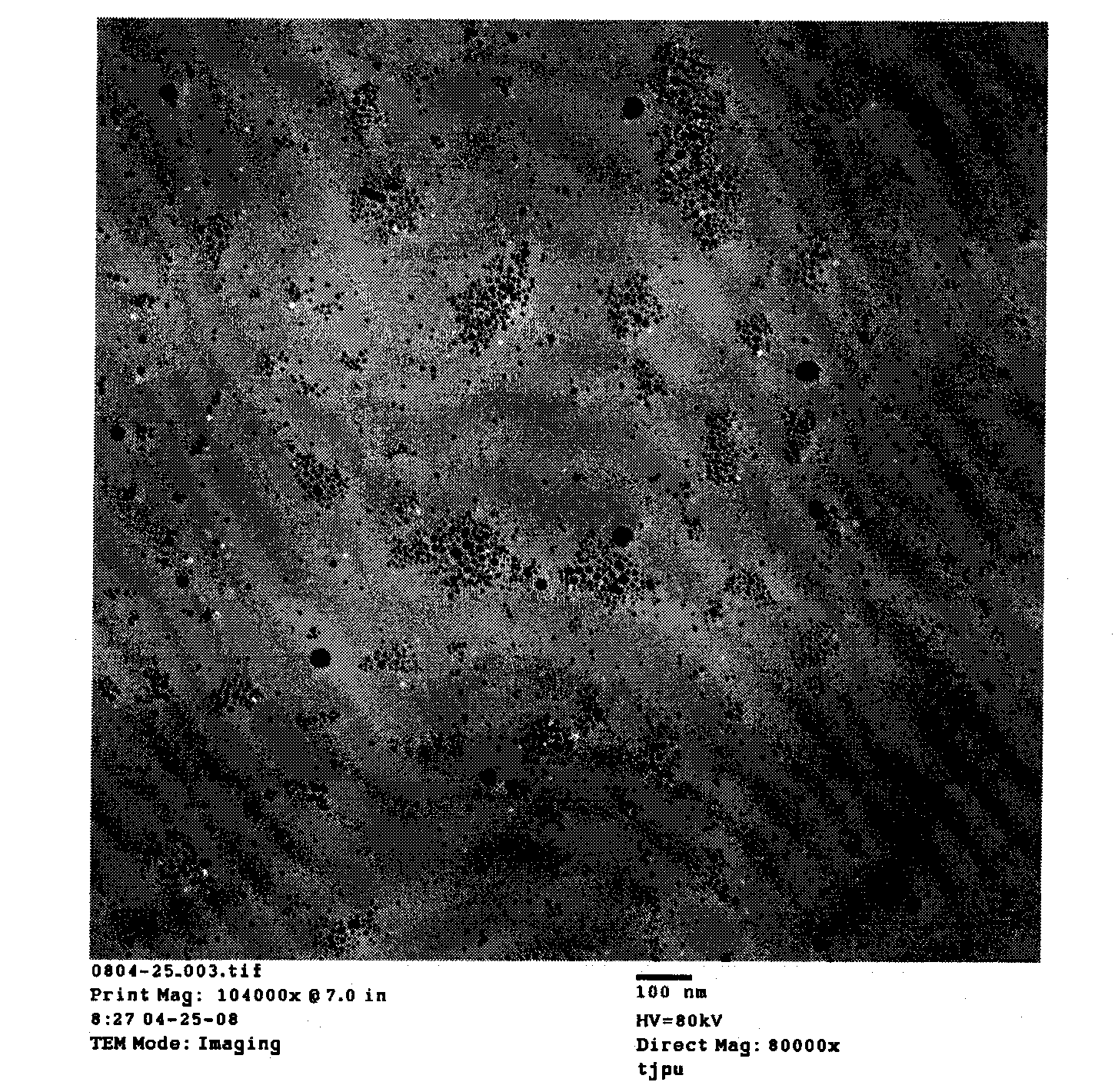

Image

Examples

Embodiment approach 1

[0015] Add 20.75mL cyclohexane and 1mL n-pentanol to an 80mL beaker, add 1g of cetyltrimethylammonium bromide under stirring, and stir until the solution is transparent (water and cetyltrimethylammonium bromide The molar ratio of ammonium is 5). Prepare two parts of the above-mentioned microemulsion, add 0.25mL 0.5mol / L hydrogen fluoride and 0.5mol / L lead nitrate aqueous solution respectively, mix the two microemulsions together after stirring for 30min, continue stirring for 30min, transfer to 80mL reaction kettle, in 120 After aging at ℃ for 12 hours, it was naturally cooled to room temperature. The obtained white precipitate was washed with isopropanol and deionized water, and dried in a vacuum oven at 80℃ for 12 hours to obtain the final product.

Embodiment approach 2

[0017] The molar ratio of water and cetyltrimethylammonium bromide in Embodiment 1 is changed to 15, and other conditions remain unchanged.

Embodiment approach 3

[0019] The molar ratio of water and cetyltrimethylammonium bromide in Embodiment 1 is changed to 20, and other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com