Spiral chute conveyer

A conveyor and chute technology, applied in the field of conveyors, can solve the problems of high investment cost and daily use cost, noise generation, adverse environmental impact, etc., and achieve the goal of reducing investment cost, saving daily use cost, and improving the equipment use environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with specific drawings and embodiments.

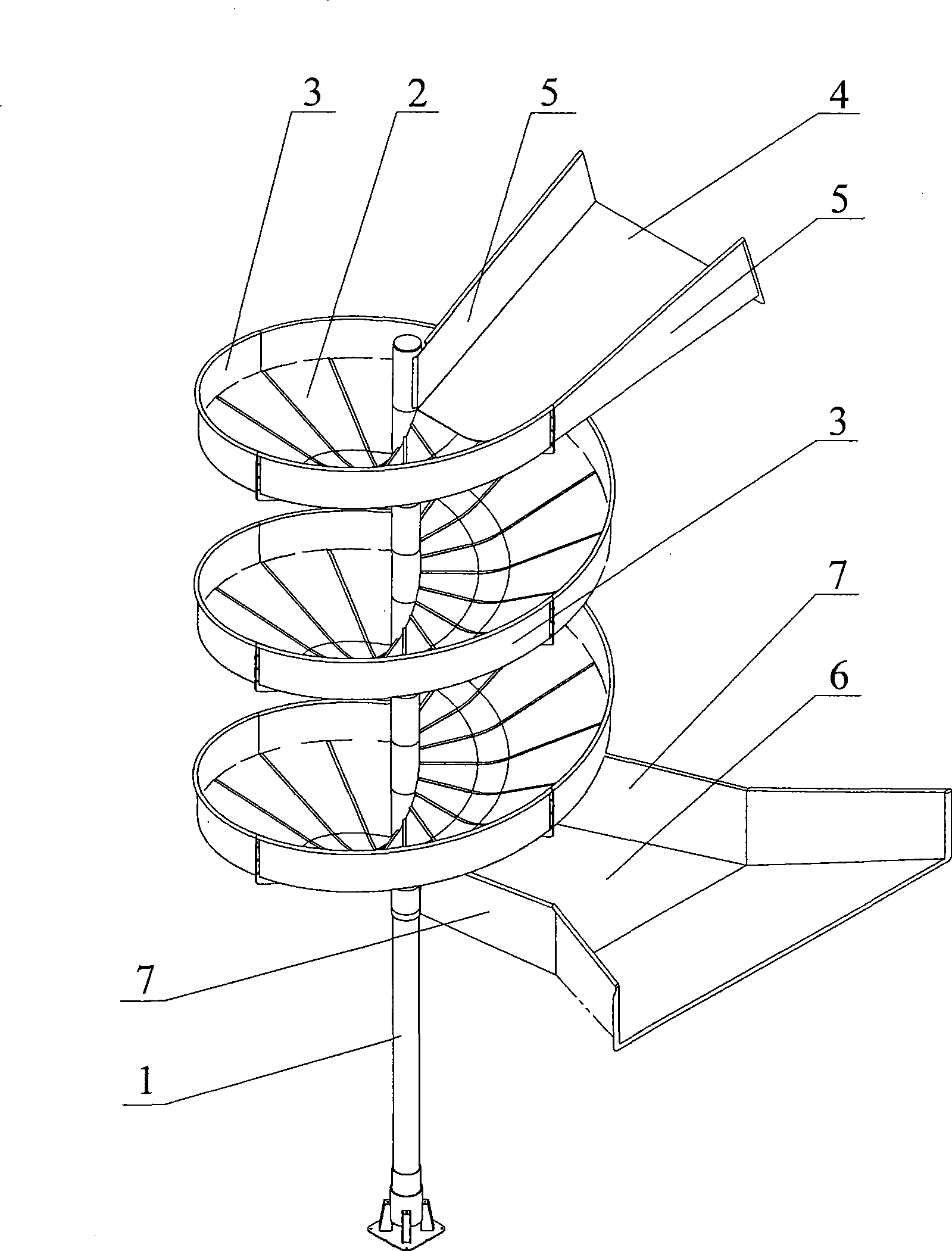

[0009] As shown in the figure: Install a spiral downward sloping slide plate 2 on the wall of the installation column 1, an upwardly protruding rib 3 is provided on the outer side of the slide plate 2, and a slideway inclined direction is provided at the top entrance of the slide plate 2. The chute inlet plate 4 provided below, the first baffle plate 5 is arranged on both sides of the chute inlet plate 4, the bottom end exit of the slide plate 2 is provided with the chute outlet plate 6 that the slideway is inclined downwardly, the chute Second baffles 7 are provided on both sides of the outlet plate 6 .

[0010] The chute inlet plate 4 is a plate with a gradually narrowing slideway from bottom to top, and the first baffle plate 5 close to the installation column 1 is arranged tangentially to the installation column 1 . The outlet plate 6 of the chute is a pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com