Paper cup making machine

A paper cup machine and paper feeding mechanism technology, applied in the field of paper cup machines, can solve the problems of heavy mold installation and commissioning, long mold processing cycle, high mold cost, etc., and achieve the advantages of highlighting substantive features, reducing molds, and reducing use and maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

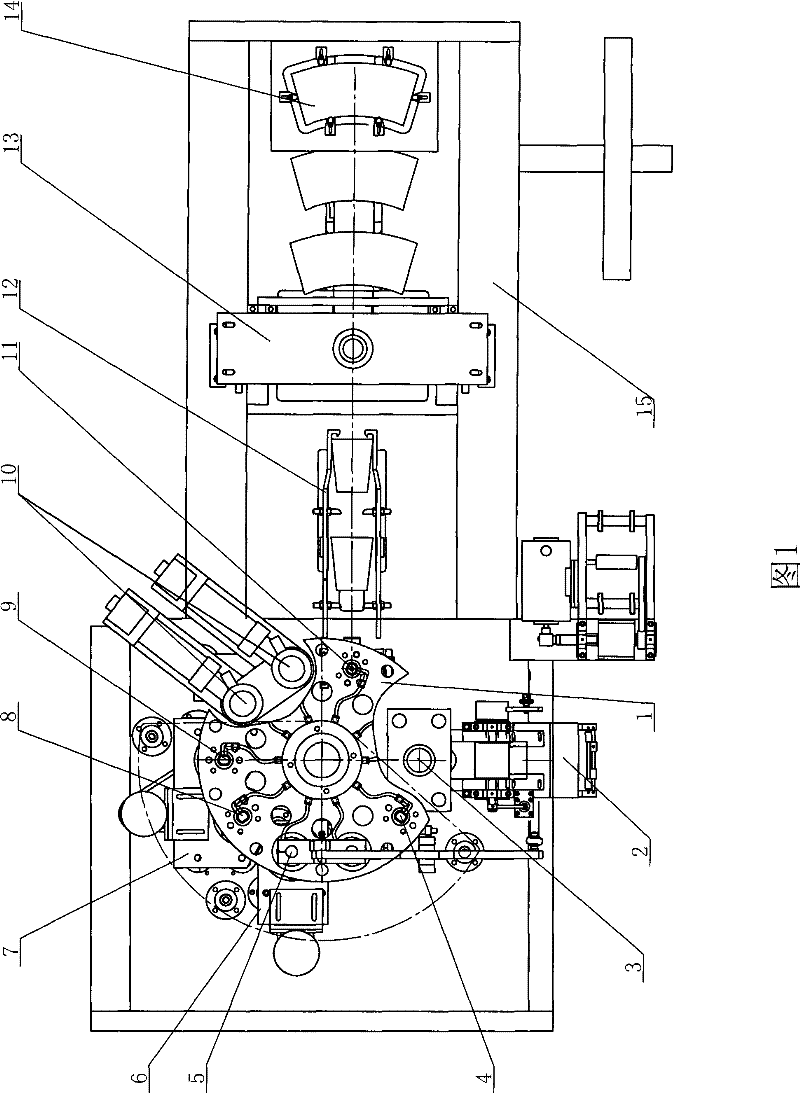

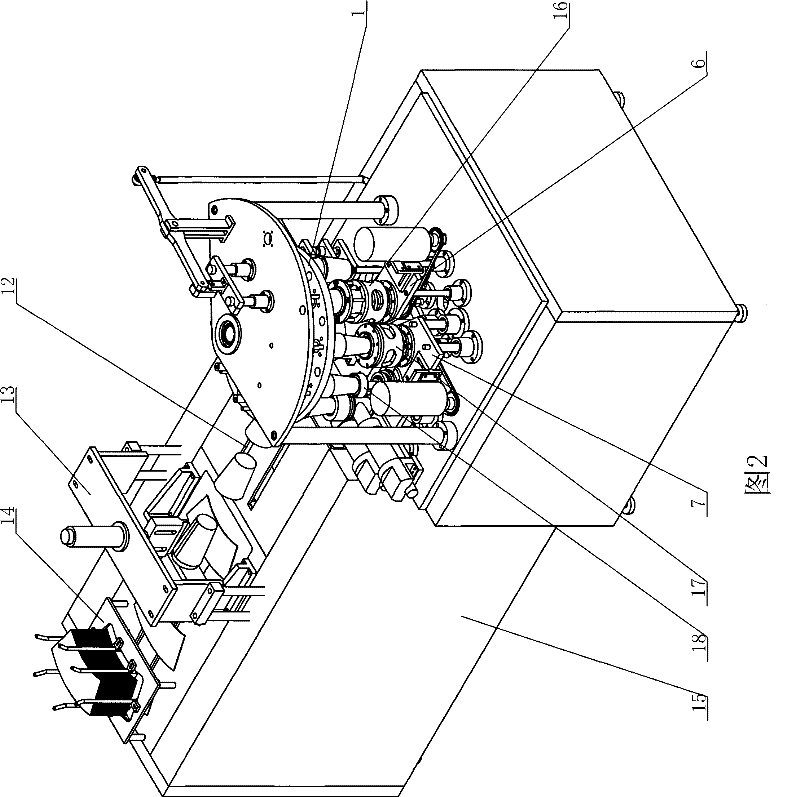

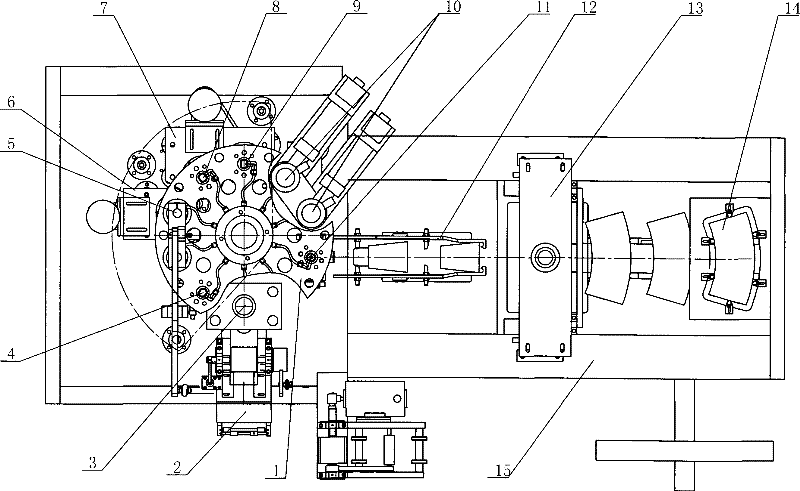

[0016] Accompanying drawing has represented technical scheme of the present invention and embodiment thereof, with reference to accompanying drawing 1, Fig. 2, this paper cup machine comprises frame 15 and is located at the cup body paper feeding mechanism 14 on the frame, cup body forming mechanism 13, sends Cup mechanism 12, indexing turntable 1, cup bottom paper feeding mechanism 2, transmission mechanism (not shown in the figure), this machine is only provided with an indexing turntable 1, and the said indexing turntable 1 is provided with bottom feeding work in turn Station 3, Cup receiving station 11, Heating station 10, Bottom folding station 9, Bottom rolling station 8, Rolling mouth station 5, Cup discharge station 4, there are corresponding working mechanisms in the above corresponding stations , the structures of these work stations are all prior art, and will not be described in detail herein; the bottom feeding station 3 corresponds to the cup bottom paper feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com