Method for driving heddle frames and weaving machine

A weaving machine and heald frame technology, applied in the field of driving heald frame, can solve the problem of large warp load and achieve good mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

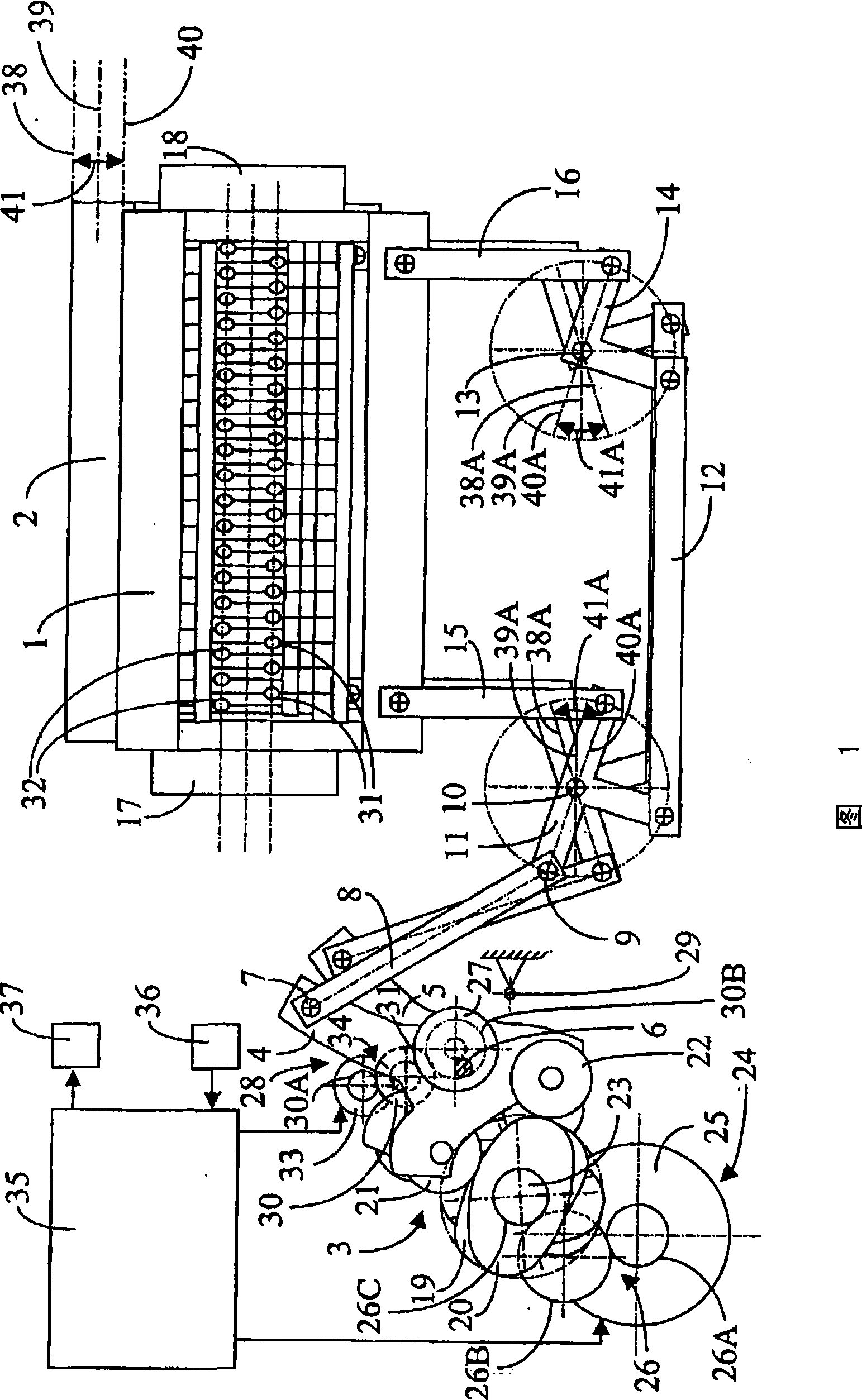

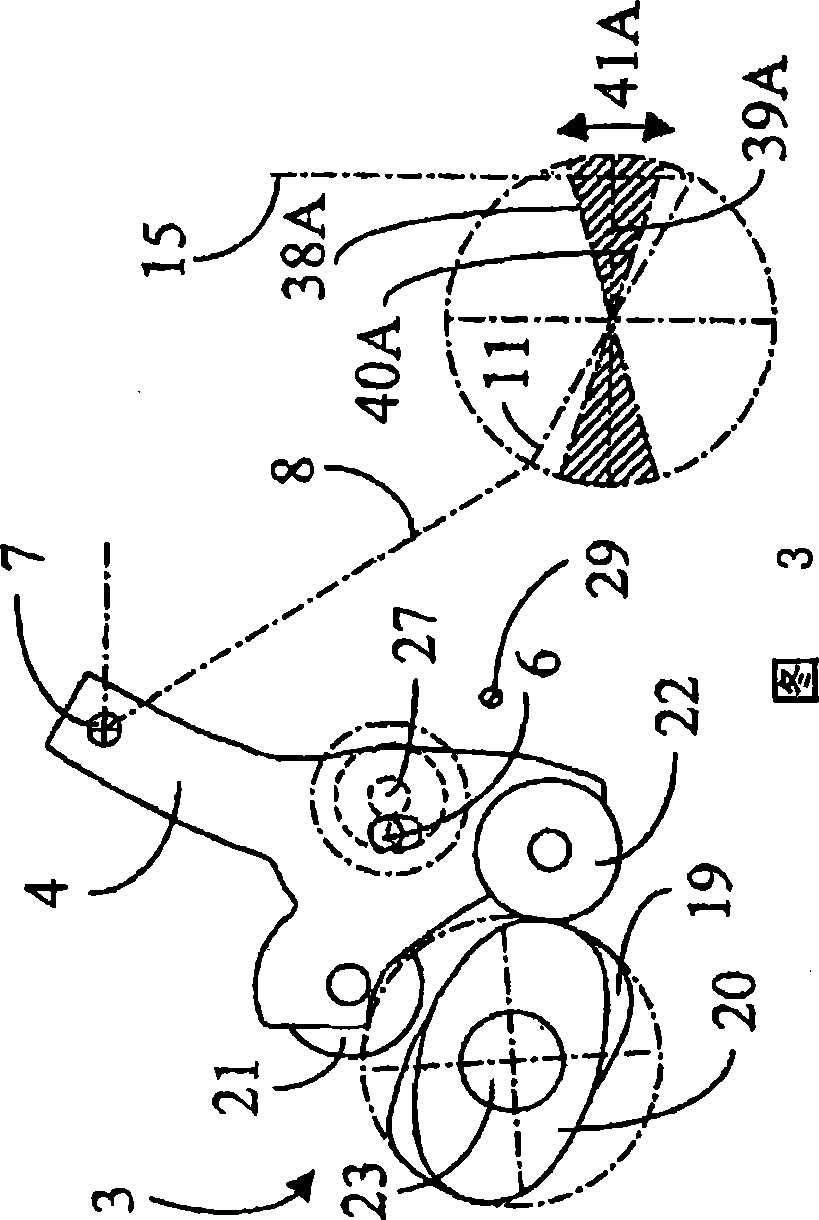

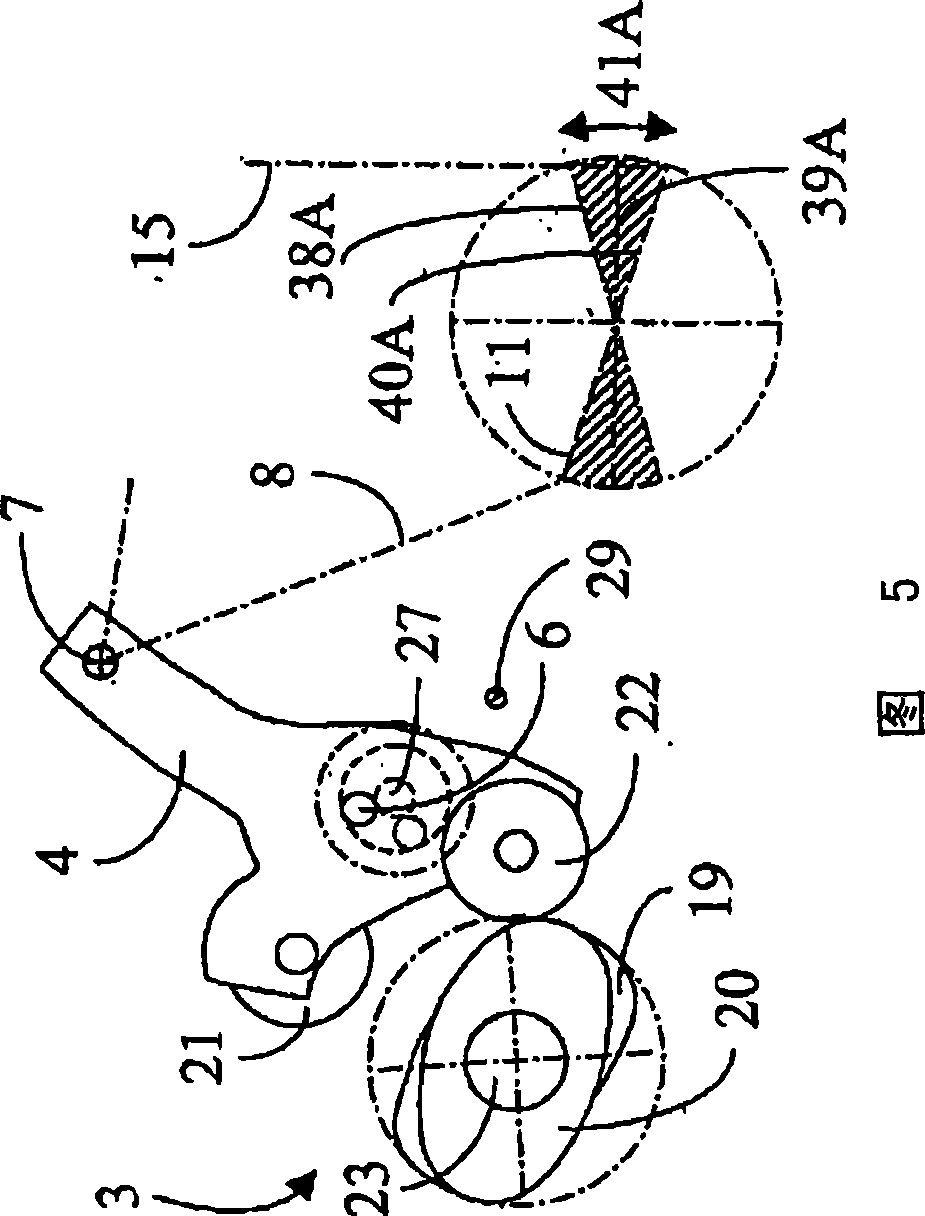

[0029] (014) The weaving machine represented in FIG. 1 comprises a number of heddle frames 1 , 2 which can be driven upwards and downwards by means of a cam system 3 . Said cam system 3 comprises control rods 4 , 5 mounted rotatably about a support shaft 6 . Each control rod 4 is connectable via a connection point 7 to a drive rod 8 , which is connectable via a second connection point 9 to a rod 11 mounted around an axis of rotation 10 . The rod 11 is connectable to a second rod 14 mounted around a rotation axis 13 via a connecting rod 12 . Each heald frame 1 , 2 is connected to the associated rod 11 , 14 via a connecting rod 15 , 16 . The rotating shafts 10 and 13 are mounted on the frame of the loom. Said heald frames 1, 2 are guided in side guides 17, 18 fitted on the frame of the weaving machine. The cam system 3 is fixedly arranged relative to the frame of the weaving machine.

[0030] (015) The cam system 3 further comprises a pair of cams 19, 20 for driving the heal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com