Rotor bearing system failure perfect information analytical method and apparatus

A technology of system failure and analysis method, applied in the direction of mechanical bearing testing, etc., can solve problems such as affecting the accuracy of fault diagnosis, and achieve the effect of improving practicability and improving intuitive identification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

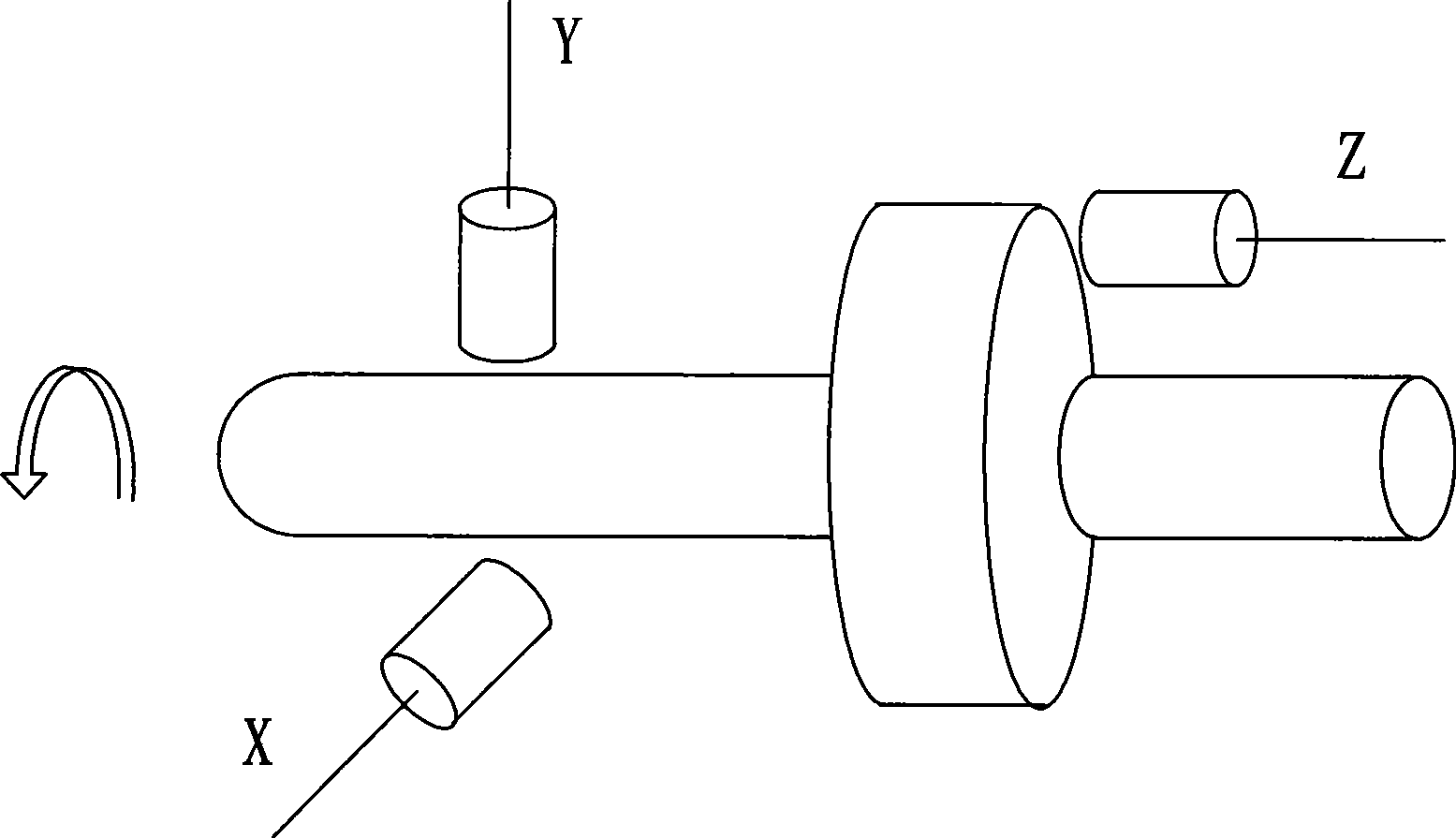

[0038] see figure 1 , figure 1 Shown is a schematic diagram of the installation position of the eddy current sensor. Two eddy current sensors are installed perpendicular to each other in the radial direction of a certain section of the rotor, and one eddy current sensor is installed in the axial direction of the rotor shaft end.

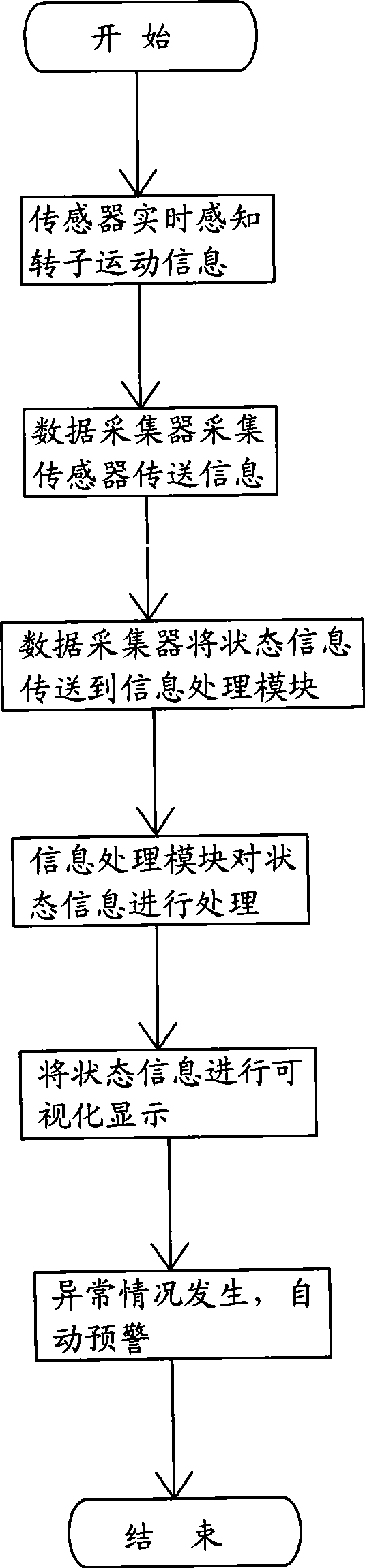

[0039] see figure 2 , the processing flow of the present invention is: utilize the data collector to gather the signal information X of each sensor DC (t), X AC (t), Y DC (t), Y AC (t), Z DC (t), Z AC (t), where X DC (t), X AC (t) respectively represent the DC component information and AC component information of the rotor in the X direction, Y DC (t), Y AC (t) respectively represent the DC component information and AC component information of the rotor in the Y direction, Z DC (t), Z AC (t) r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com