Catalyst for producing vinyl acetate by acetylene method and preparation method and use thereof

A vinyl acetate and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of low production capacity, high reaction temperature and high cost , to achieve the effect of good catalytic performance, good mechanical strength and easy loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0012] Example 1:

[0013] Acrylonitrile and vinylidene chloride were distilled to remove the polymerization inhibitor to obtain monomers, and the molar ratio of acrylonitrile and vinylidene chloride was 1.5:10. The initiator is azobisisoheptonitrile, and the amount is 1-2% (molar ratio) of the monomer amount. The copolymer pellets are obtained by suspension polymerization. The particle size of the polymer pellets is controlled by adjusting the stirring speed. The polymerization temperature is 40℃, polymerization time is 24 hours. After the reaction, the pellets are repeatedly washed with boiling water to remove the dispersant. The polymer pellets are put into a quartz tube, and the temperature is gradually raised to 1000℃ under the protection of argon and kept at 1 -3 hours to obtain the copolymer-derived carbon pellet catalyst carrier. The above method is used to obtain carbon pellet carriers with different ratios of acrylonitrile and vinylidene chloride.

Example Embodiment

[0014] Example 2:

[0015] Weigh 30 g of the derivatized carbon prepared in Example 1, and calculate the amount of mixed solution required for impregnation. Weigh 1.92g Zn(CH 3 COO) 2 ·2H 2 O was dissolved in a mixed solvent of methanol and water, zinc acetate was loaded on the derivatized carbon by an equal volume impregnation method, and after drying, a catalyst for the production of vinyl acetate with a zinc acetate loading of 5% was obtained.

[0016] Using the above method, catalysts with different zinc acetate loadings were prepared.

Example Embodiment

[0017] Example 3

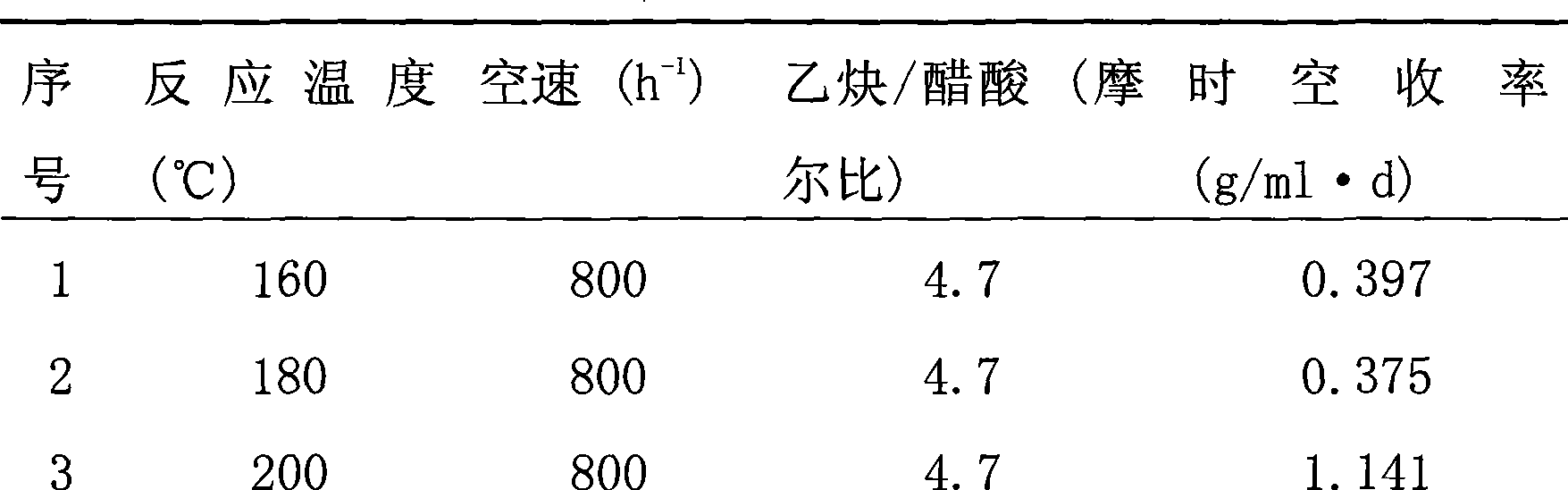

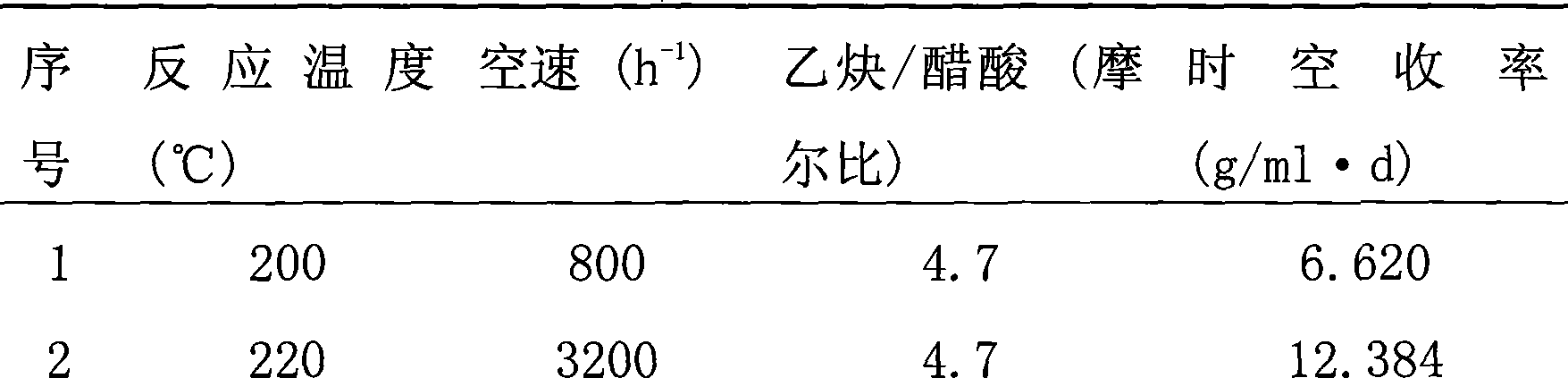

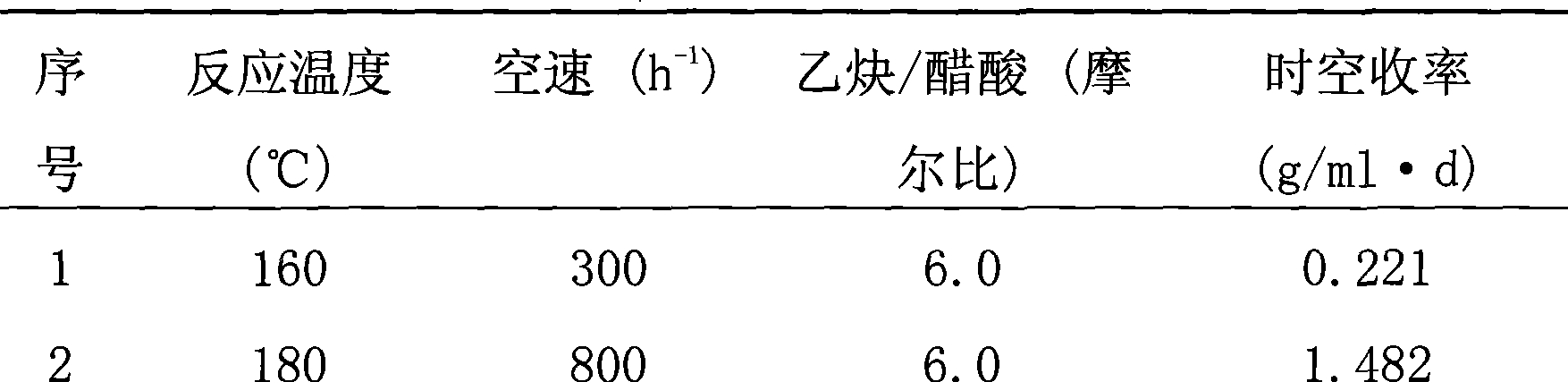

[0018] 20g of catalysts with different loadings of zinc acetate were loaded into the fixed bed reactor. The heating medium of the reactor is heat-conducting silicone oil. Acetylene comes from a steel cylinder, and acetic acid is pumped in by a metering pump. The reaction products are collected in the condenser and analyzed quantitatively by chromatography. By changing the reaction temperature and the space velocity of the gas, the reaction results under different reaction conditions are obtained, as shown in Table 1.

[0019] Table 1 Catalytic reaction results of the catalyst with a zinc acetate loading of 5wt%

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com