Method for the manufacture of lantibiotics

A technology of lantibiotics and cell culture, applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve problems such as complex preparation methods of lantibiotics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

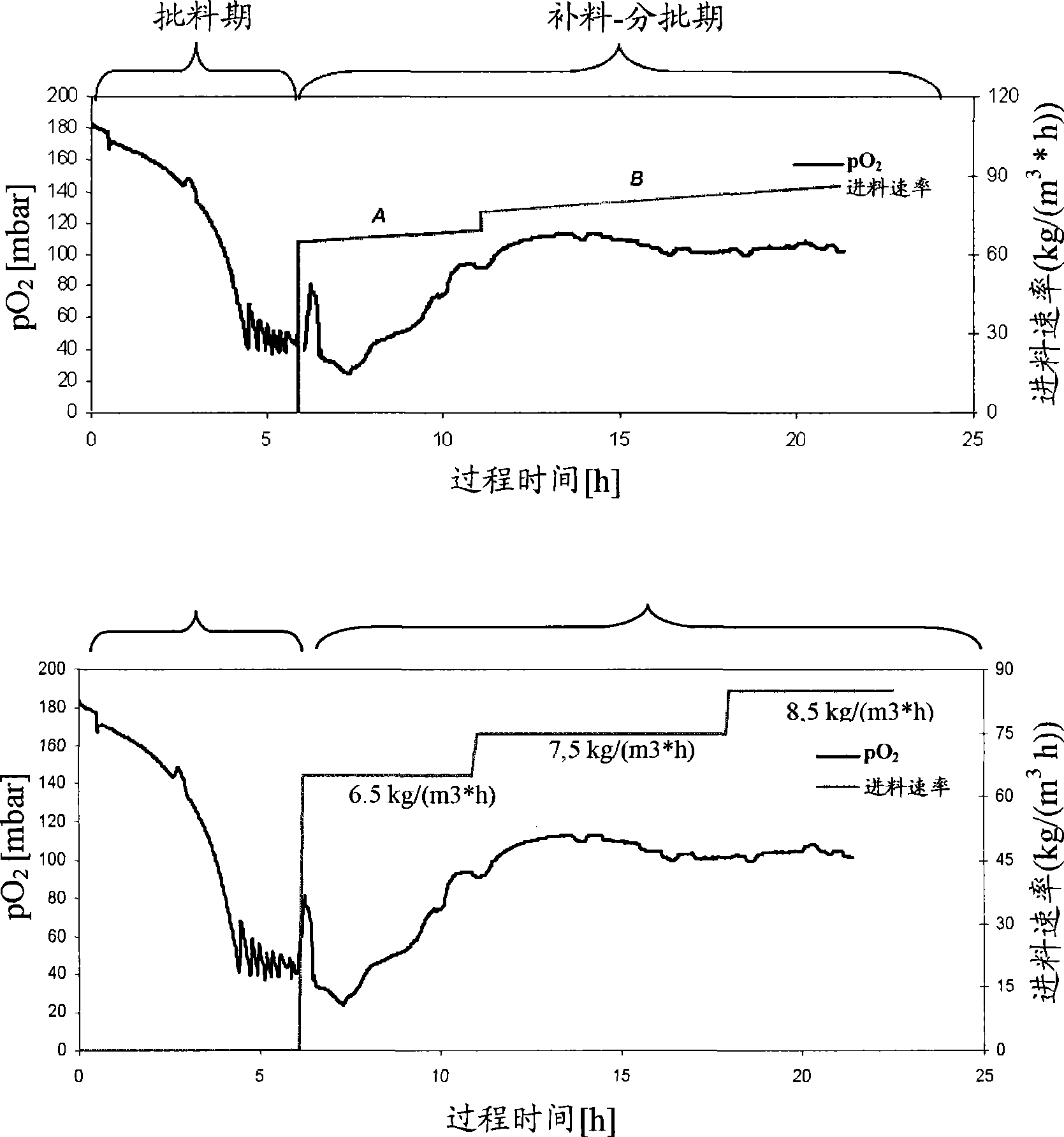

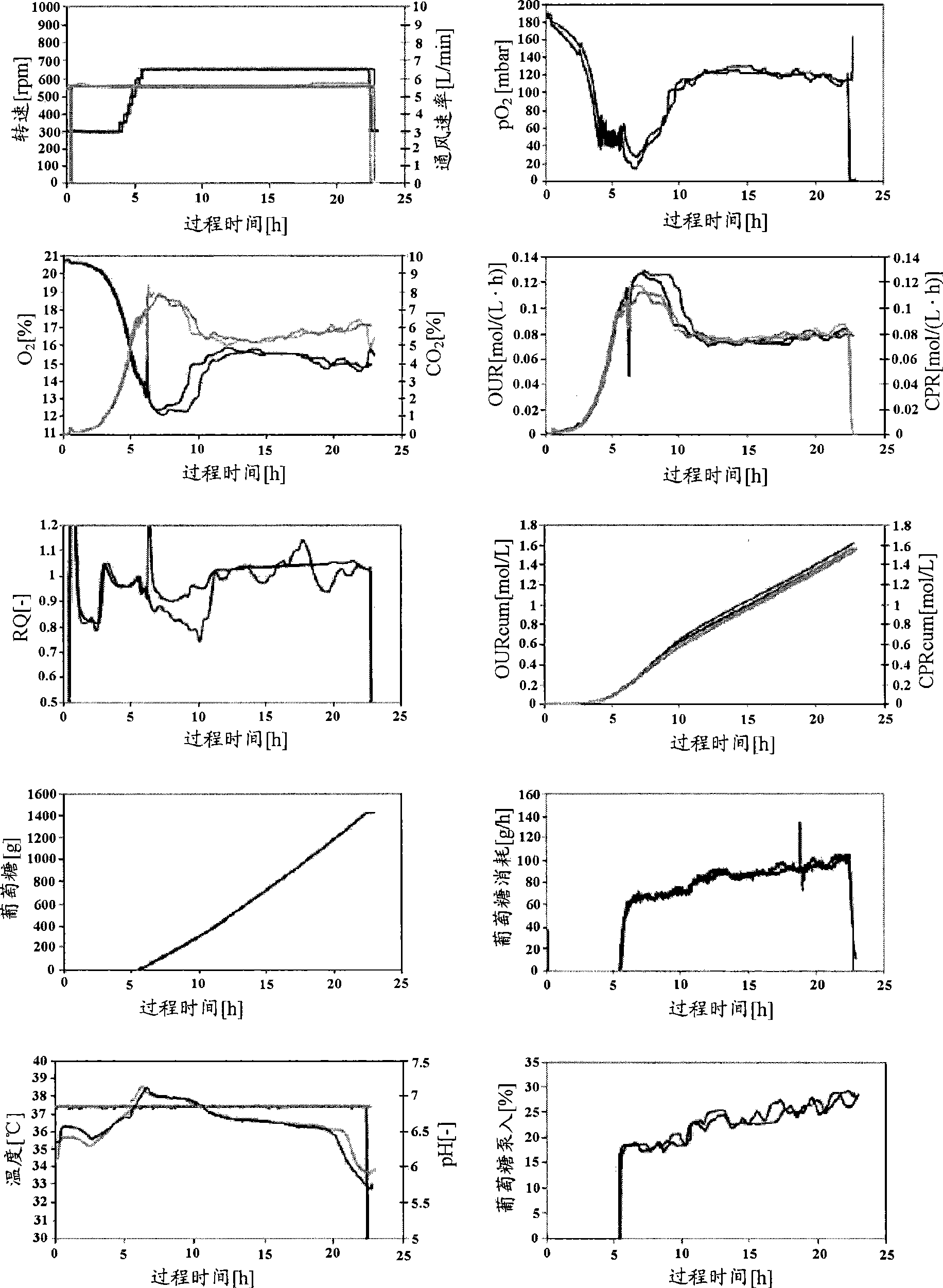

[0059] Fermentation of gallidermin

[0060] Freezing culture (WCC):

[0061] A vial of frozen stock (Zellbank BO-002; Kampagne 1940122004033, Reference 35 / 3 / 18) of Staphylococcus gallinarum (Tü 3928; DSM4616) was used to sterile inoculate the agar plates. The agar culture was incubated at 37°C for 1 day, followed by 1 day at 4°C (with Parafilm - but this step is not necessary). This culture was used to inoculate the first generation of seeds. For each production, a new vial must be used.

[0062] plate culture medium

[0063] Yeast Extract Hy-Yest 455 5g / L Kerry Bioscience Glucose x H2O 1g / L Cerestar or Merck NaCl 5g / L Fluka or Merck Bacto Agar 12g / L Bekton Dickinson h 2 o Deionization pH 7.3 (before sterilization)

[0064] Preculture or first generation seeds (2 shake flasks; 500ml):

[0065] One cultured plate (approximately 0.5 x 0.5 cm) was aseptically transferred into two 500 ml baffled shake flasks (a ba...

Embodiment 2

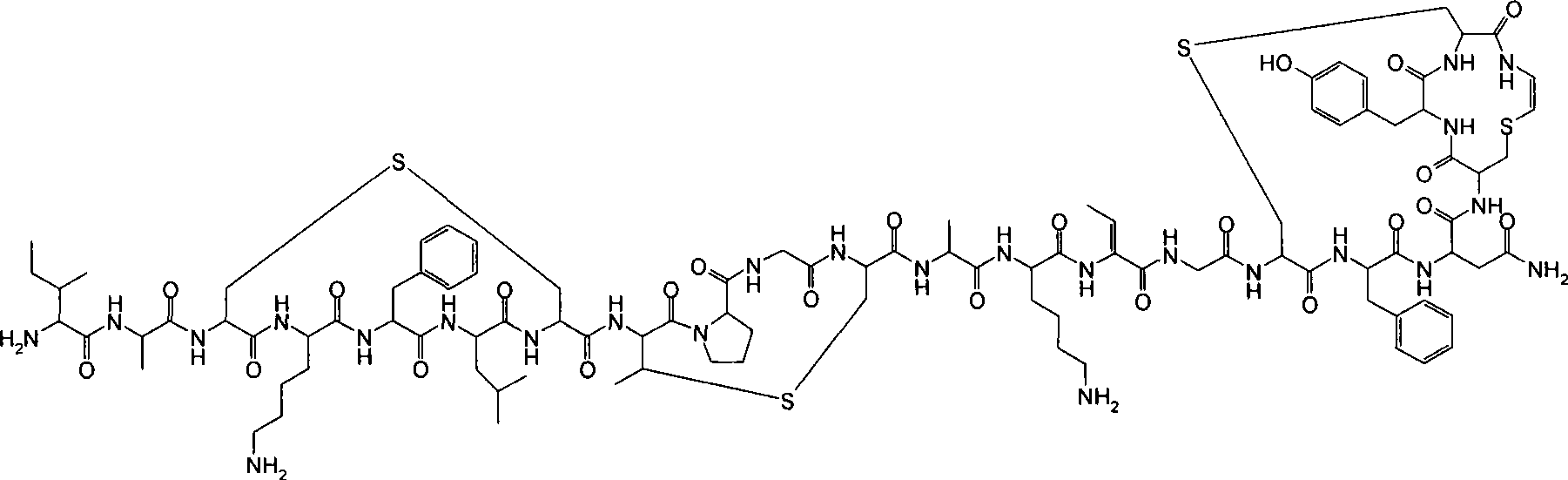

[0086] Purification of gallidermin

[0087] Starting from the culture supernatant of the fermentation process as described in Example 1, gallidermin was purified as follows:

[0088] Method A: Precipitation with Ammonium Sulfate

[0089] After fermentation, the cells were removed by centrifugation, and the cell-free supernatant (pH 6. 7) to precipitate the product.

[0090] In a separate experiment, precipitation with various concentrations of (saturated) ammonium sulfate was tested.

[0091] % Saturation of Ammonium Sulfate Yield(%) 20 9 30 31 40 69 50 76 60 74

[0092] The suspension was stirred slowly for another 30 minutes, then the precipitate was collected by filtration. The precipitate was dissolved in 40% ethanol, 1% aqueous acetic acid (1 / 4 of the starting volume). The yield of the product was 87% with a purity of 93.6 area % as determined by analytical HPLC.

[0093] The purity of the product can be further improved to >...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com