Process for rapidly cleaning surface of nickel-coated billet cake

A steel billet and nickel-clad technology, which is applied in the field of rapid cleaning process of nickel-clad steel billet cake surface, can solve the problems of large product quality fluctuation, secondary pollution, high work intensity, etc., achieve low cleaning cost and labor intensity, increase service life, Good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

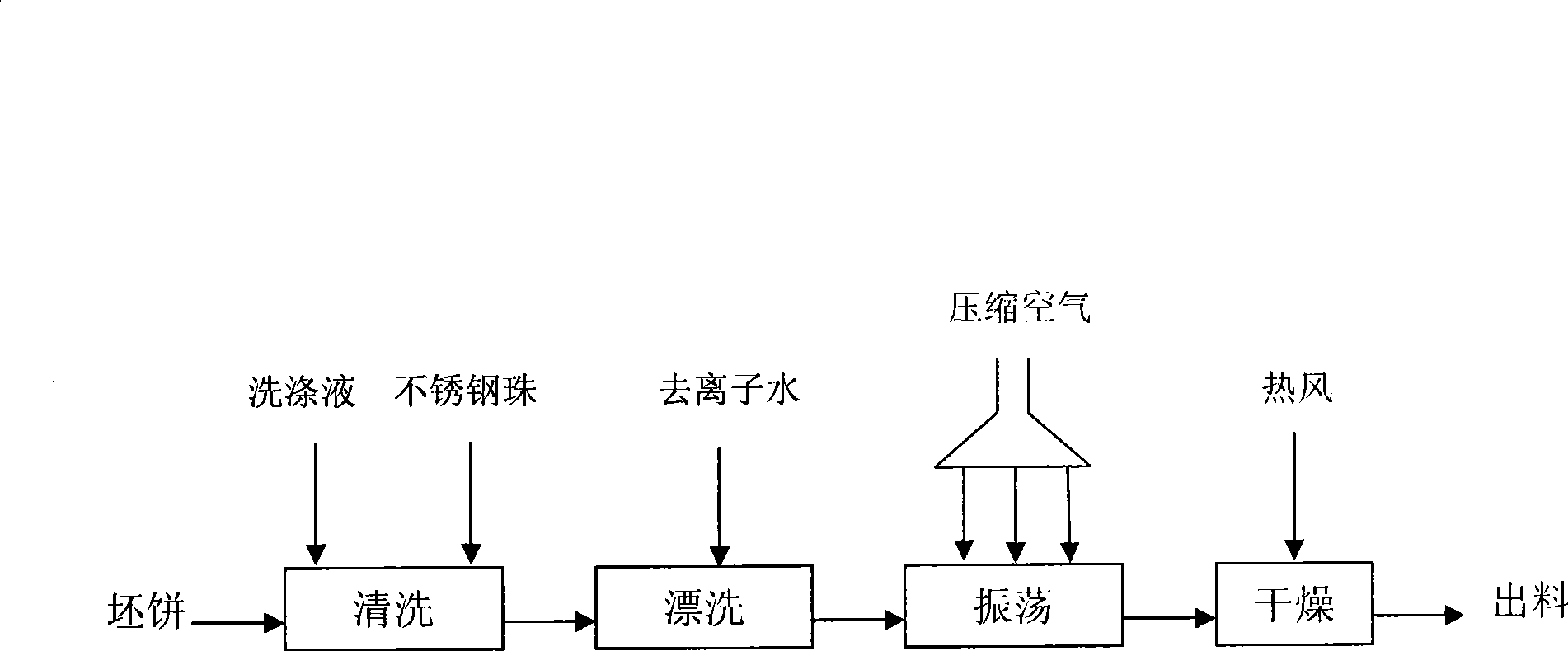

[0030] See attached figure 1 , Put the nickel-clad steel billet into the washing liquid for cleaning, after cleaning, rinse with deionized water, blow off with compressed air vibration, and dry with hot air to form a clean billet, wherein: the washing liquid is composed of detergent A, detergent B, alcohol, WA The dehydrating agent and water are mixed, and the specific steps are as follows:

[0031] (1), preparation of washing liquid

[0032] A. Mix and prepare detergent A by following components, and described substance is by weight percentage:

[0033] Sodium stearate (content ≥ 98%): 16%

[0034] Sodium oleate (content≥90%): 16%

[0035] Nonylphenol polyoxyethylene ether (content≥99%): 15%

[0036] Sodium silicate (content ≥99%): 8%

[0037] Sodium sulfate (content ≥ 99%): 12%

[0038] Sodium carbonate (content ≥ 99.1%): 10%

[0039] Borax (content≥99%): 8%

[0040] Alkanolamide (content≥92%): 15%

[0041] B. Mix and prepare detergent B by following components, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com