Corrosion inhibitor of internal combustion engine cooling liquid and production process

A technology for internal combustion engines and coolants, applied in water/sludge/sewage treatment, chemical instruments and methods, descaling and water softening, etc., can solve problems such as misleading research directions, rare raw materials, high prices, etc., to overcome toxicity problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Add the corrosion inhibitor of the present invention to tap water, clean well water, river water and spring water, and the ingredients in it will form a dense, thin and tough film on the metal surface to slow down cavitation and corrosion. The scale inhibitor and scale dissolver It can make the scale-forming ions form stable complexes and prevent scale deposition.

[0014] The patent is illustrated below with some examples that can illustrate the present invention rather than limit the present invention. Unless otherwise specified, all percentages are percentages by mass.

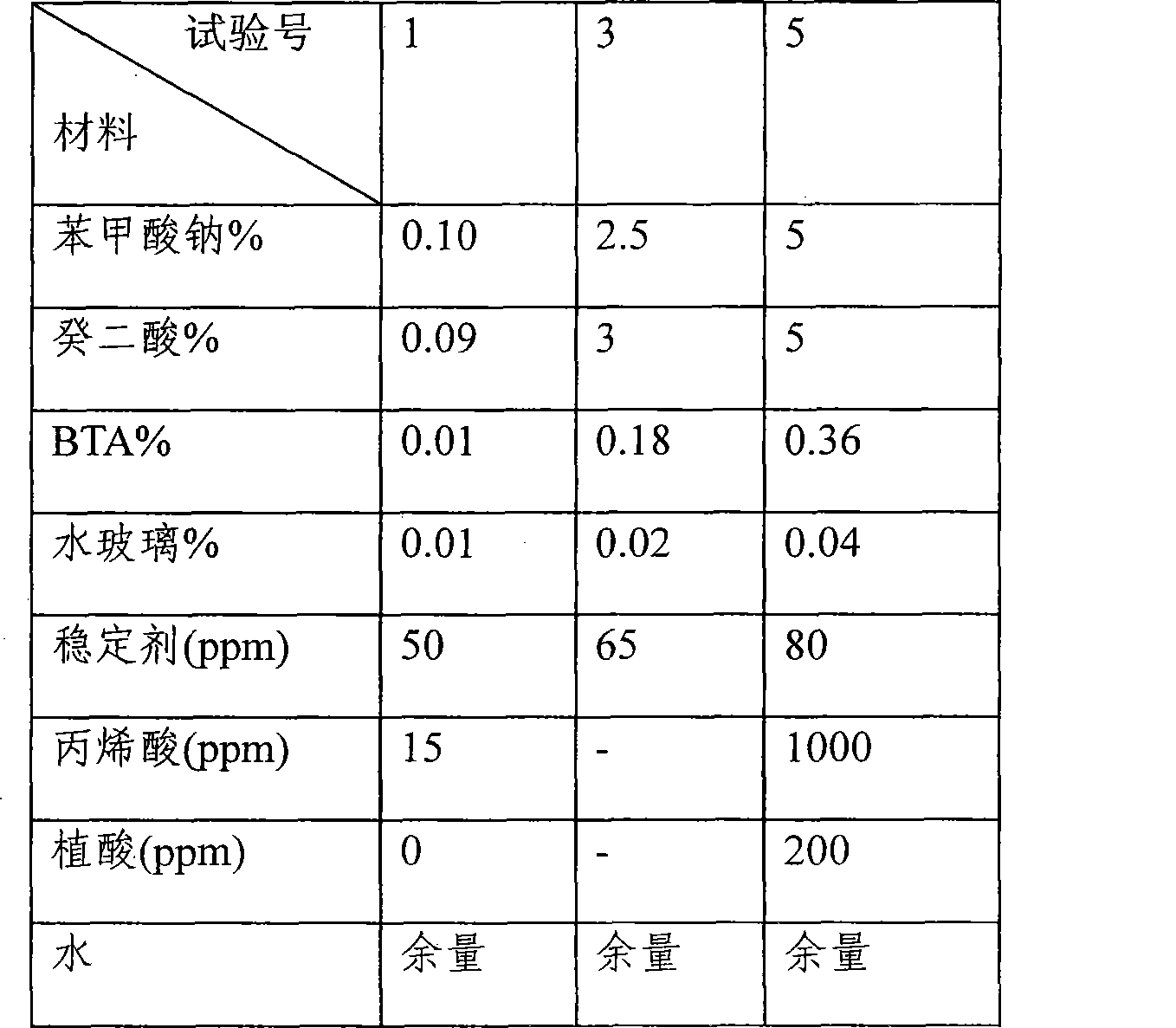

[0015] Example 1 According to the components in Table 1, adjust the pH value of the solution with sodium hydroxide to be 8-9 to prepare a corrosion inhibitor and rust preventive agent

[0016] Table 1 Composition of samples

[0017] sample Phytic acid Borax Hydroxyphenylhydrazine carbohydrazide polyacrylamide sodium hydroxide water 1 1% 0.3% 0.5% 0.01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com