Printer-labeler and labeler

A technology for labeling machines and printers, applied to labeling machines, typewriters, labels, etc., can solve problems such as inability to ensure that labels are removed, and peeling has started

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A printer-labelling machine and a labeling machine each embodying the present invention will be described below with reference to FIGS. 1 to 8 .

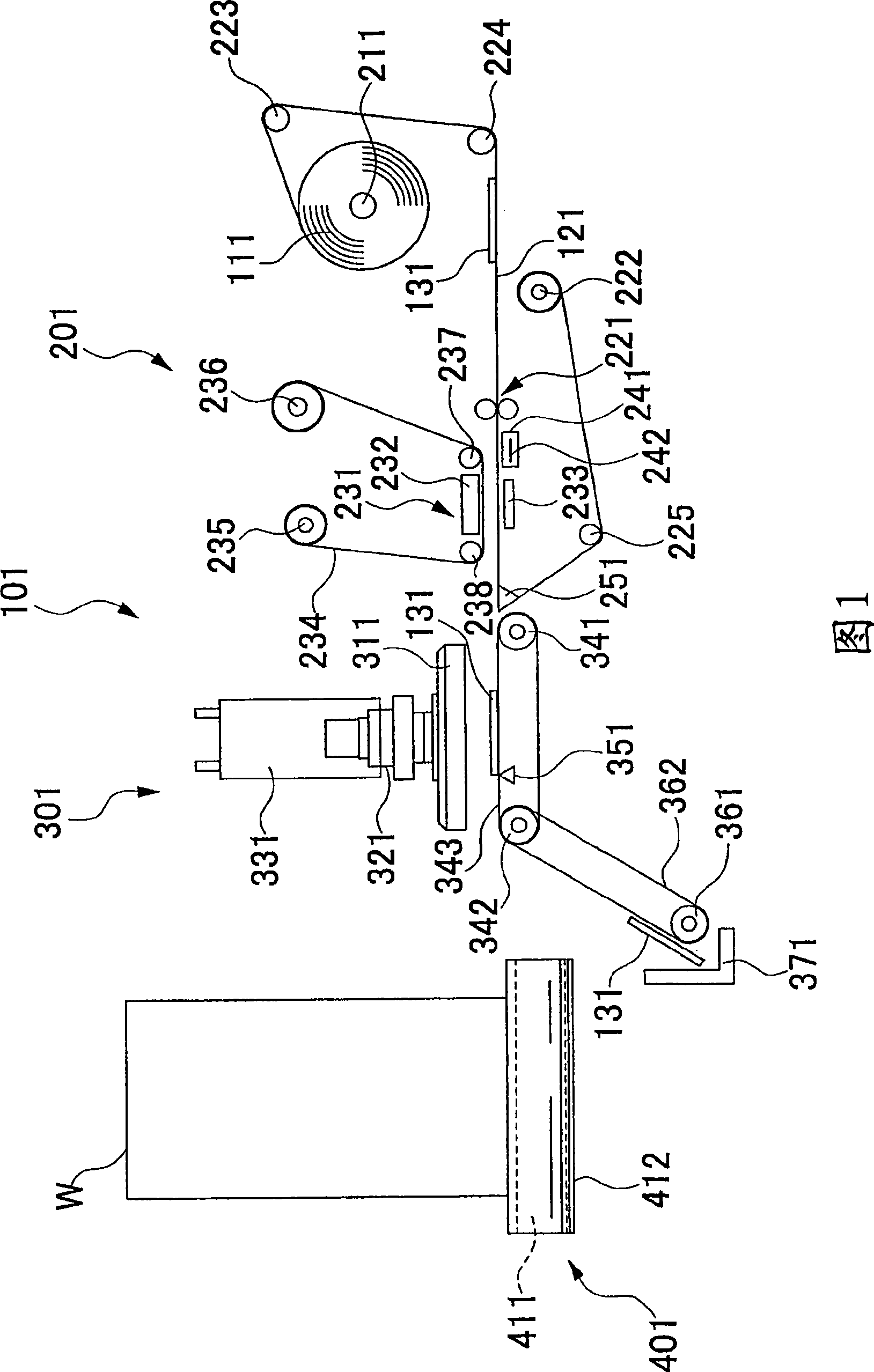

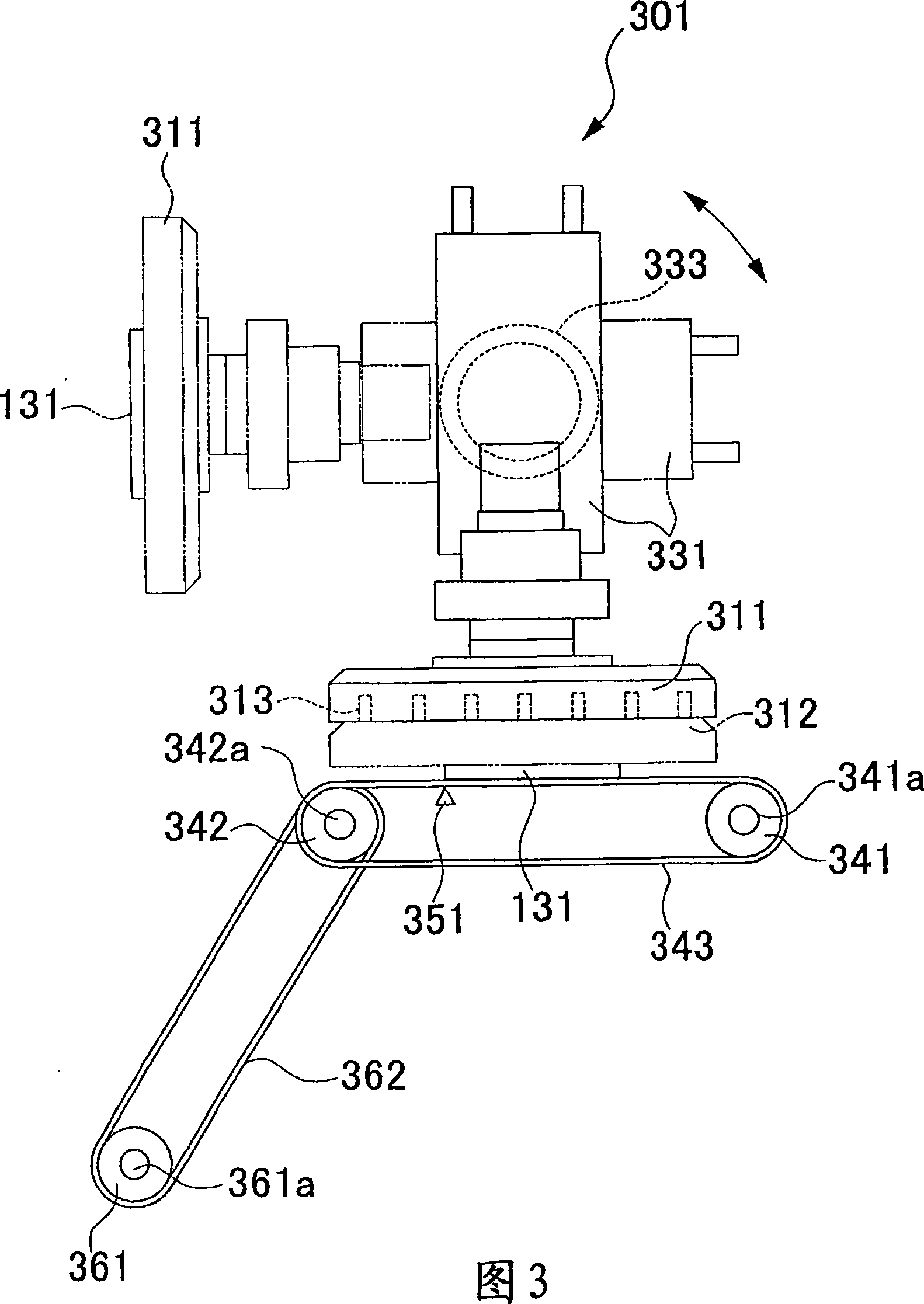

[0025] As shown in FIG. 1 , a printer-labeling machine 101 embodying the present invention mainly includes a printer 201 and a labeling machine 301 arranged side by side. Adjacent to the printer-labeller 101, a workpiece transfer unit 401 is provided. The workpiece transfer unit 401 transfers the workpiece W, which is an object to which the label 131 is to be attached, to a position facing the labeling machine 301 .

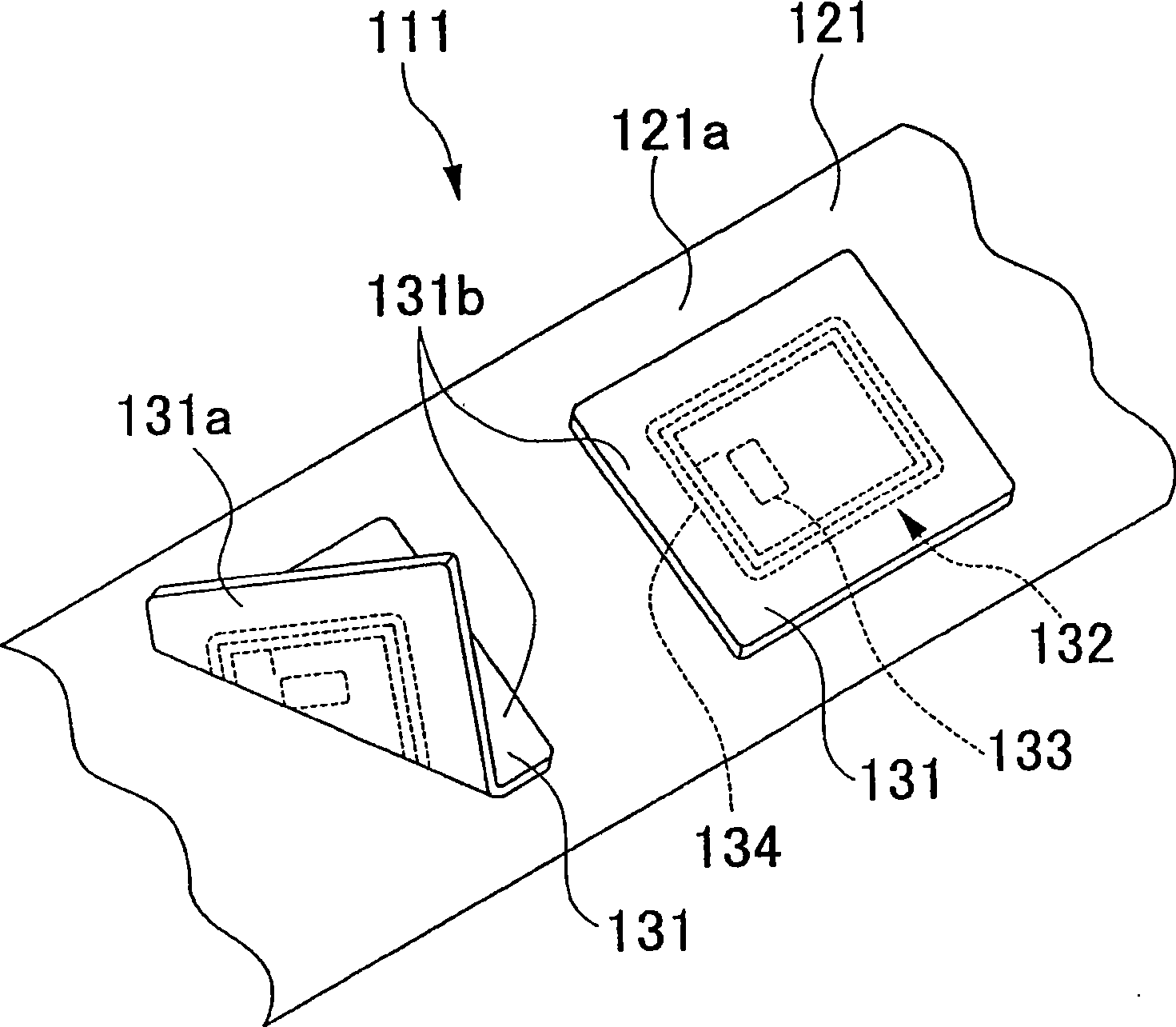

[0026] First, a description is given about the printer 201 . A holding shaft 211 that rotatably holds rolled label paper 111 is provided inside a housing (not shown) of the printer 201 . The label paper 111 has a structure in which a plurality of labels 131 are arranged at predetermined intervals on a long base paper 121 (see figure 2 ).

[0027] The label paper 111 held by the holding shaft 211 is drawn out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com