Forming device for producing food with three layers of different stuffing and method

A molding device and molding method technology, applied in the field of spherical raw food, can solve the problem of inability to form spherical food and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

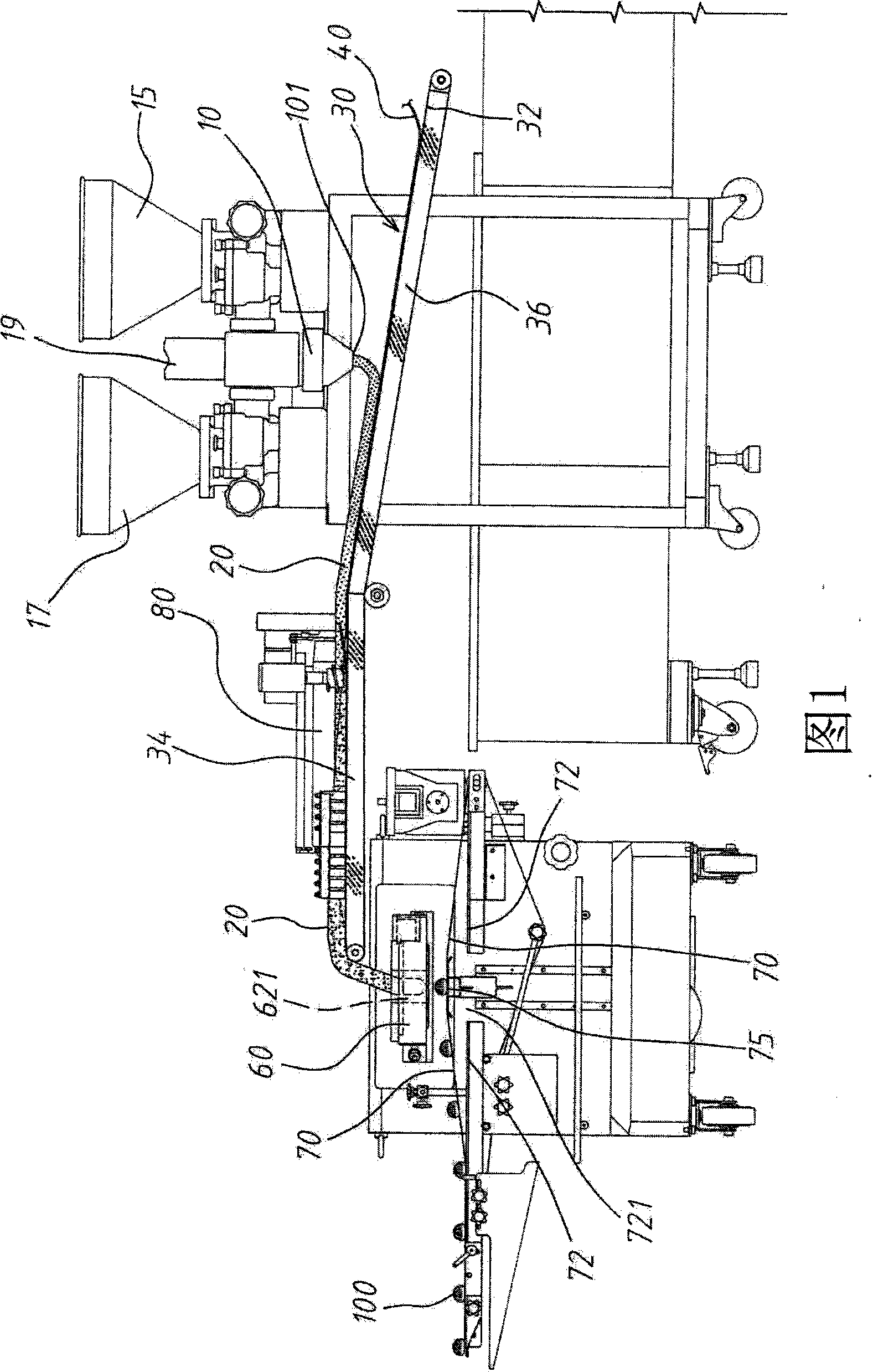

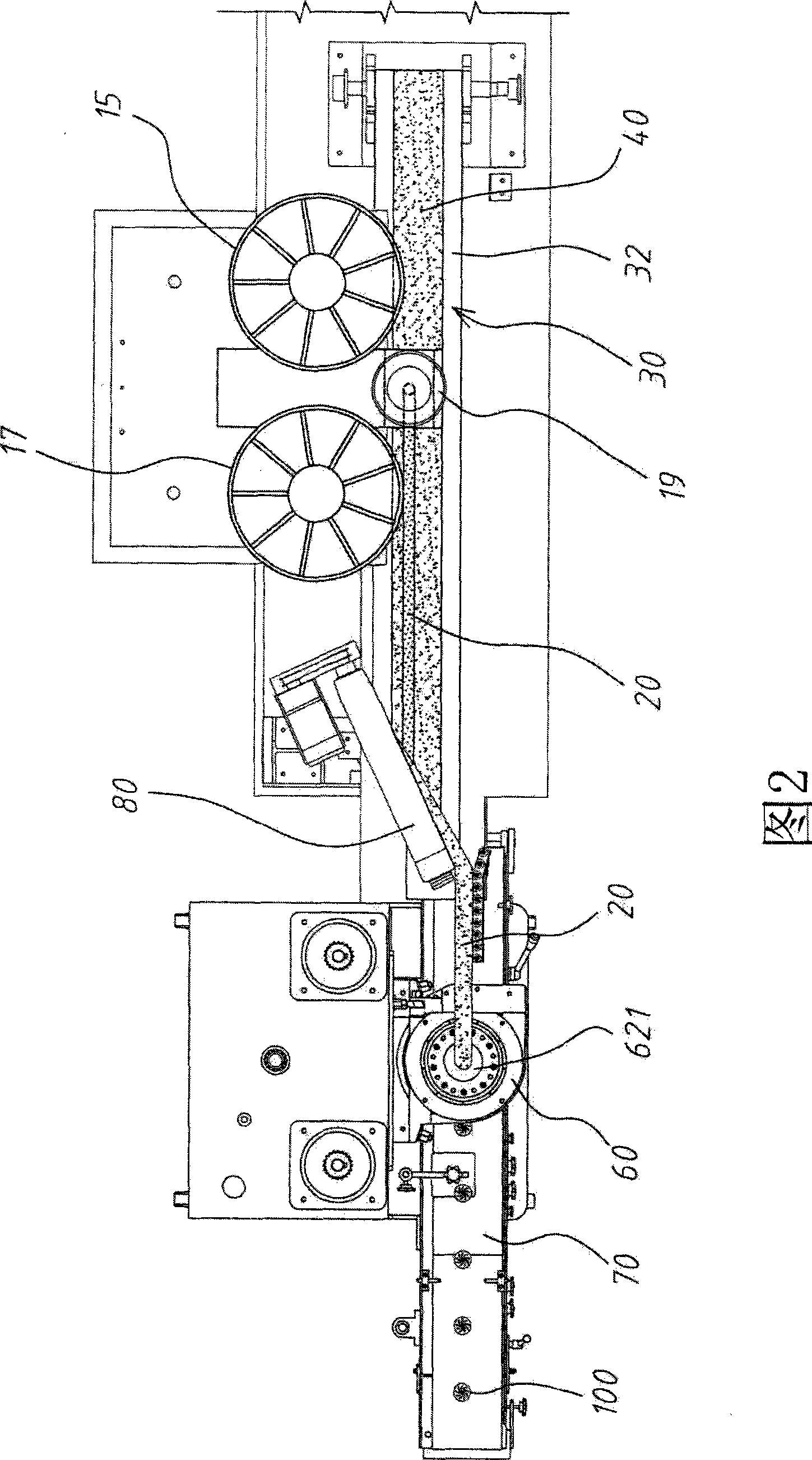

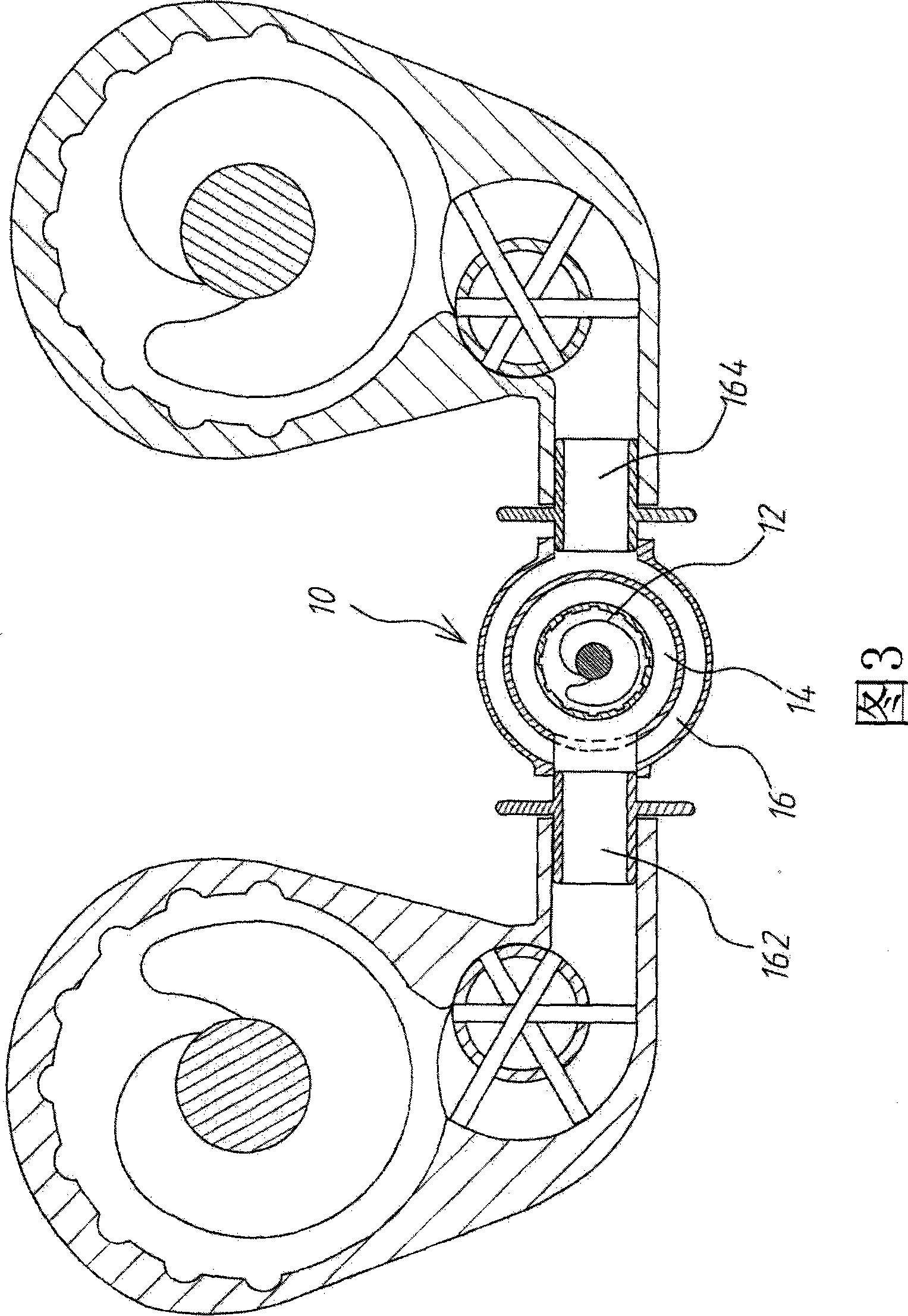

[0052] As shown in Figure 1, Figure 2, and Figure 3, a molding device for producing food with three layers of different fillings includes:

[0053] A combined nozzle 10 capable of outputting three layers of fillings. The combined nozzle 10 has an inner passage 12, a middle passage 14 and an outer passage 16. (The middle passage 14 has a circular ring shape and is arranged around the Outside the inner layer passage 12, the outer layer passage 16 has a circular ring shape, and is arranged outside the middle layer passage 14) The inner layer passage 12 can output a solid round strip-shaped inner layer filling 121 (as shown in FIG. 5), the middle passage 14 outputs a circular middle filling 141, the middle filling 141 wraps the inner filling 121, and the outer passage 16 outputs a circular outer filling 161, so The outer filling 161 described above wraps the middle filling 141 to form a three-layer filling cylindrical filling 20 from the outlet 101 of the combined nozzle 10, and is ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com