Formwork seal butt-joint rim and unionized type adjustable structure

A technology for butt joints and formwork, which is applied to the joints of formwork/formwork/workframes, building structures, and on-site preparation of building components. and other problems to achieve the effect of preventing slurry leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

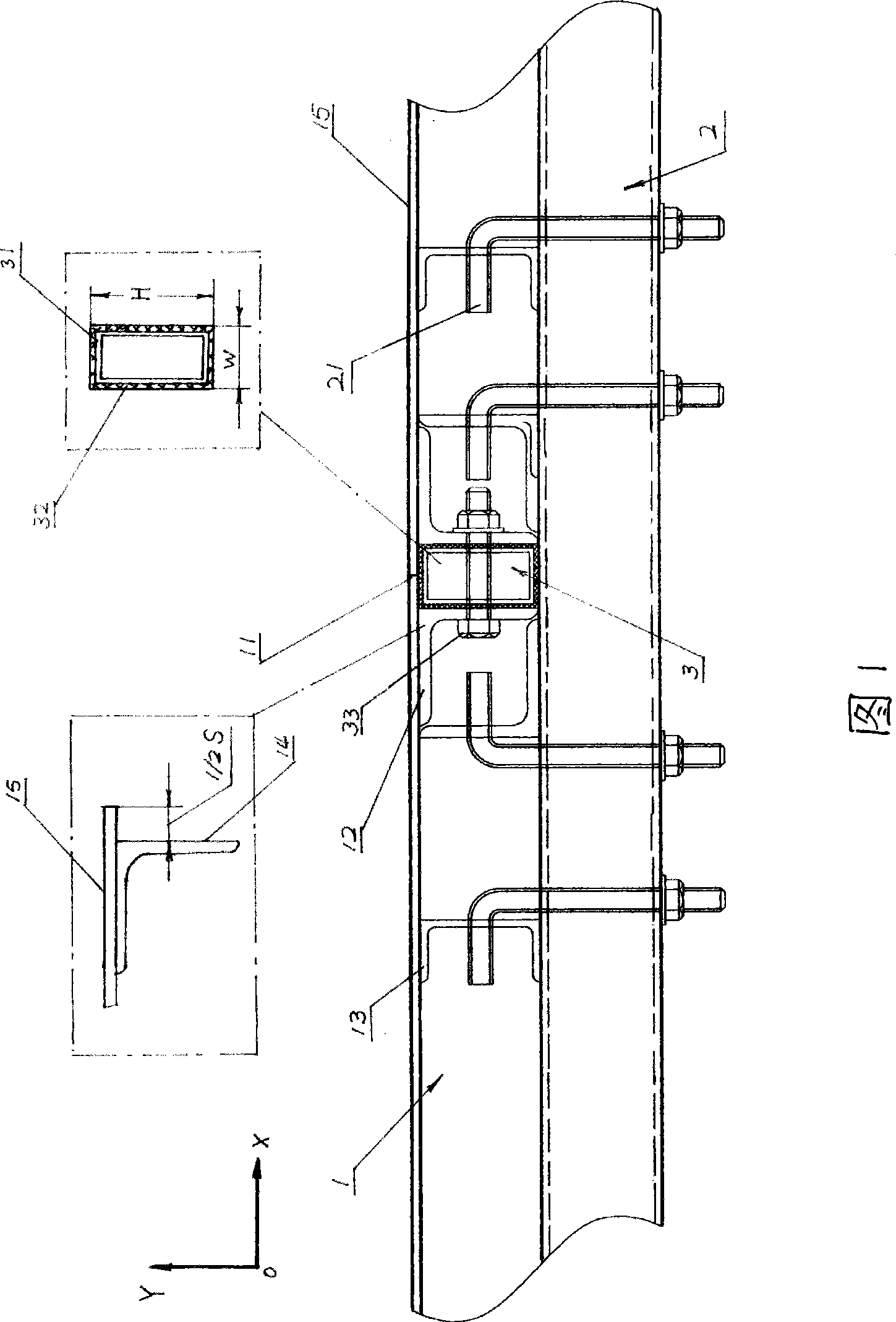

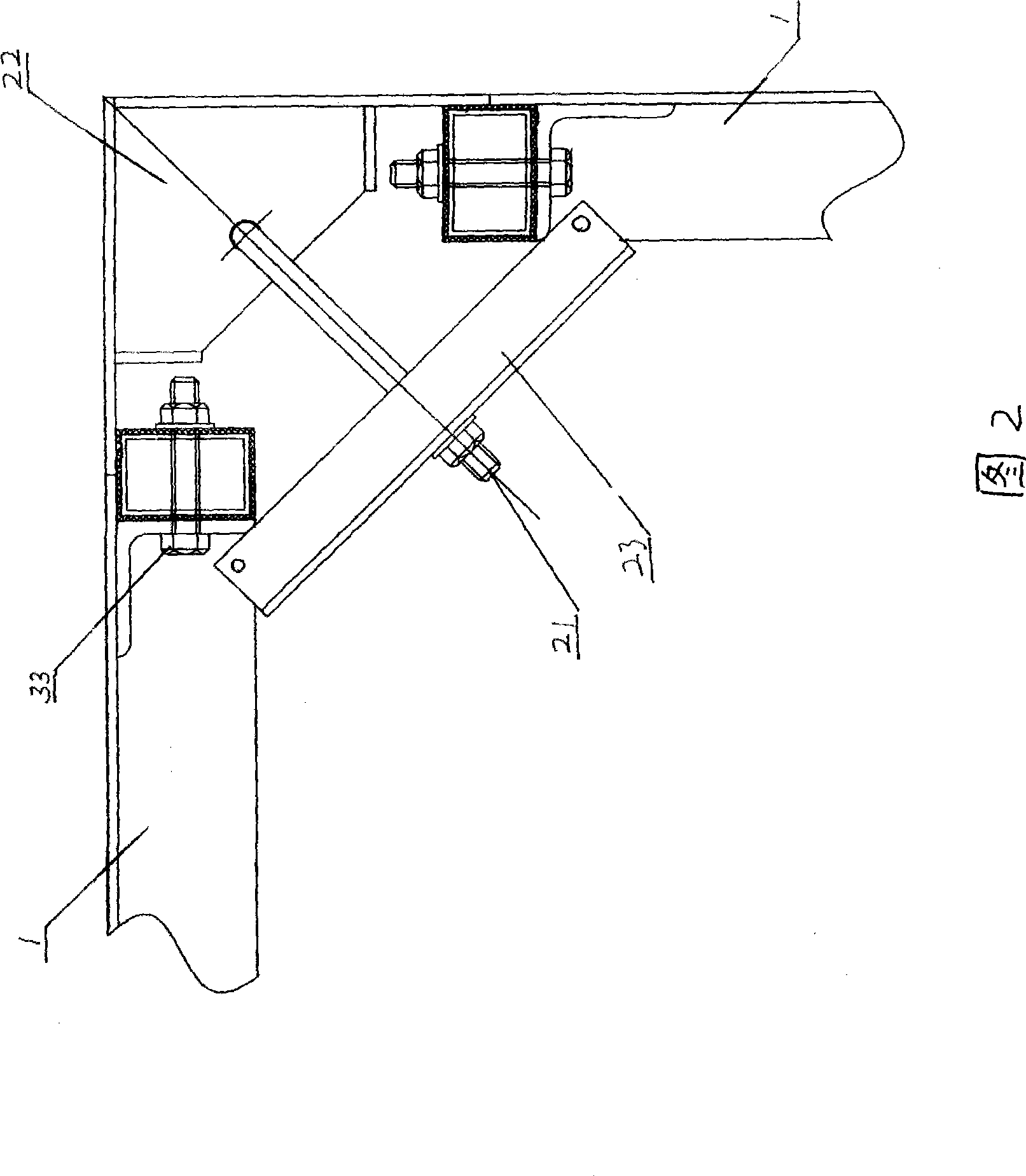

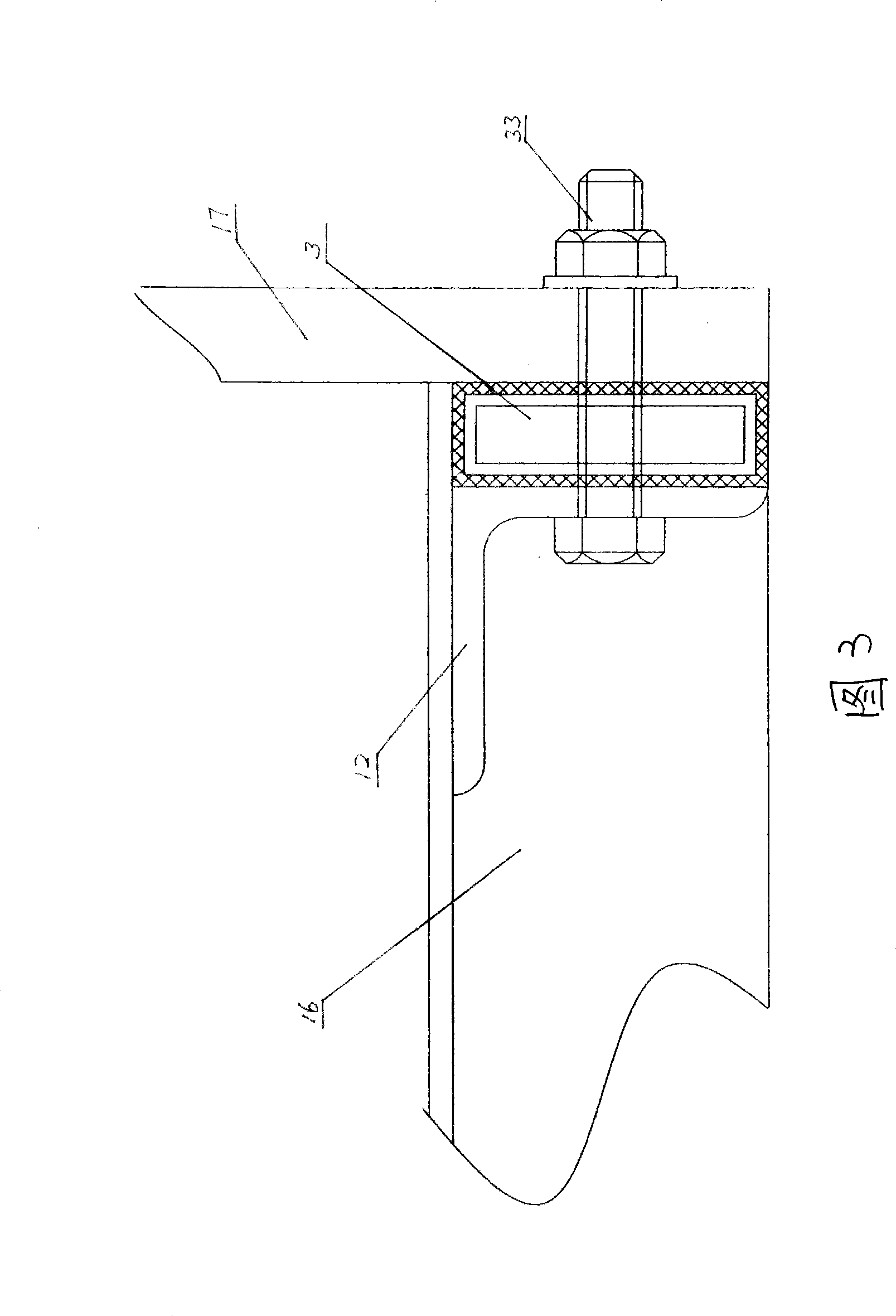

[0014] As shown in Figure 1, a formwork sealed butt joint edge and unified adjustable structure is mainly composed of a formwork 1, a reinforcing rib 2 and a butt joint edge adjustment member 3, wherein two corner profiles 12 are arranged at the butt joint edge 11 of the formwork 1 , the edge of the formwork plate surface 15, the opposite corner profile side wall 14 protrudes outward for a distance of 1 / 2S, and the gap of size S is formed between the two planar formwork 1 corner profile side walls 14, and a steel pipe sleeve 31 is provided. The butt edge adjustment part 3 composed of the elastic sleeve 32 is put on, and the two together form an adjustable butt edge structure of a unified structure. The width W of the butt edge adjustment part 3 should be slightly larger than S, and the height H should be equal to the side wall of the corner profile The length of 14, the setting of width W and height H should be able to eliminate the deviation in the X direction and Y direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com