Heavy fraction oil hydrotreating method

A heavy distillate oil, hydrotreating technology, applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problem that catalytic cracking products do not meet the requirements of clean fuels, and reduce equipment investment and operating costs , load reduction, and effect improvement

Active Publication Date: 2011-10-12

CHINA PETROLEUM & CHEM CORP +1

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, FCC products do not qualify as clean fuels

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~4

[0025] Table 1 Raw Oil Properties

[0026] Raw oil name

[0027] *Raw oil-1 is mixed oil (where VGO:CGO:DAO=50:25:25 weight ratio)

[0028] **The raw material oil-2 is mixed oil (where VGO:CGO=60:40 weight ratio)

[0029] Table 2 Main composition and properties of hydrotreating catalyst

[0030] catalyst

[0031] CoO, wt%

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

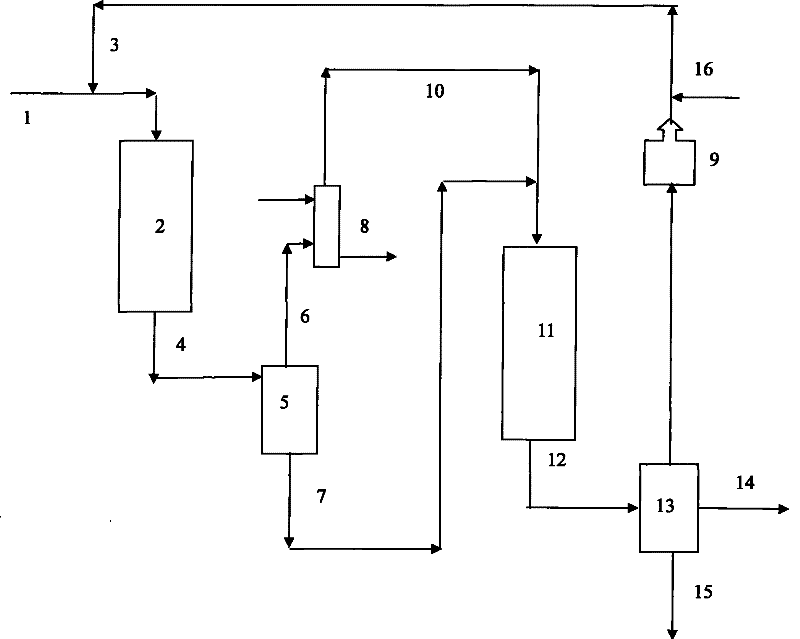

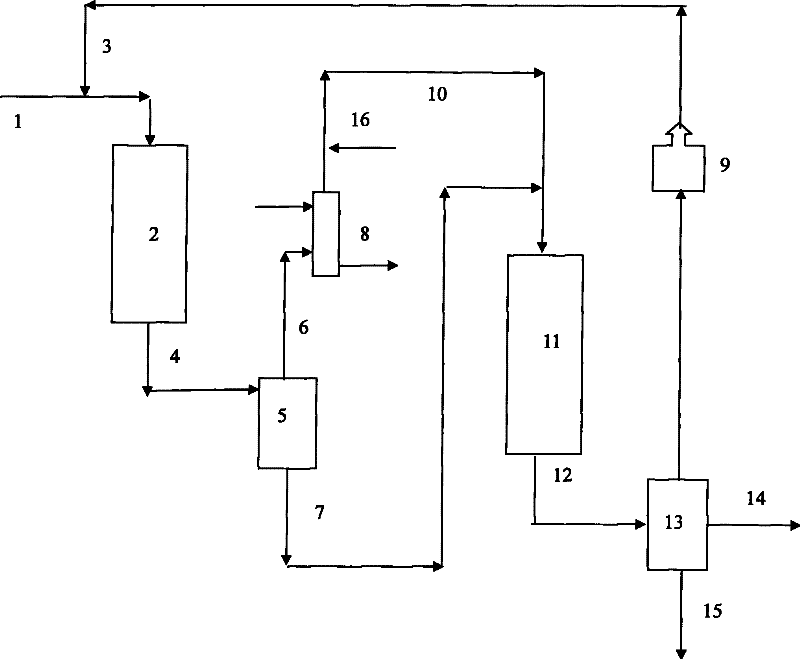

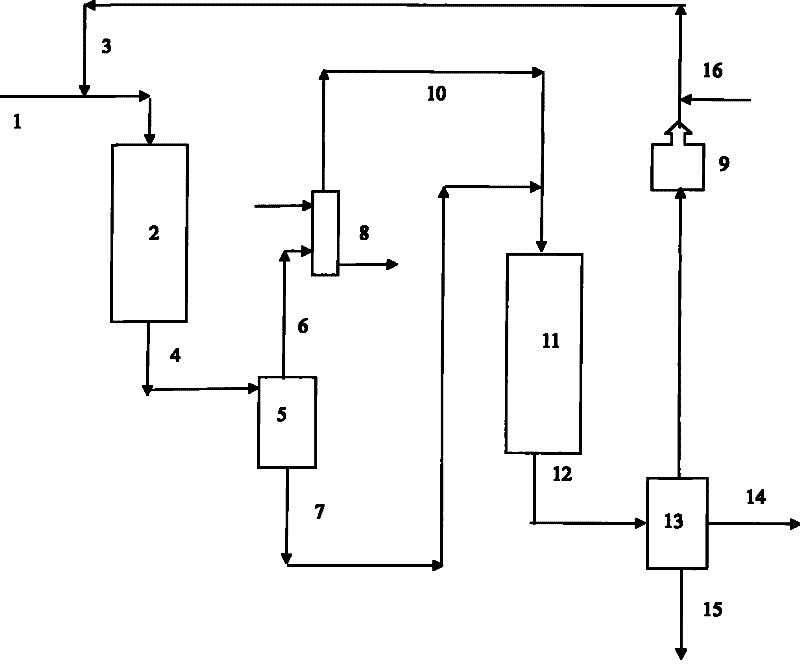

The invention relates to a hydrotreatment method of heavy diesel fractions. The heavy diesel fractions are used as material oil; under the hydrotreatment conditions, the material oil and circulated hydrogen are mixed and pass through a first hydrotreatment reaction area; gas and liquid are obtained through the high pressure separation of the oil generated by the hydrotreatment; the gas after being desulfurized is mixed with the liquid and then passes through a second hydrotreatment reaction area; the oil generated by the hydrotreatment is separated in a high pressure separator; the gas obtained through separation after passing through a compressor enters the first hydrotreatment reaction area; the liquid obtained through separation obtains a low-sulfur light oil product and a heavy oil product in a fractionating tower. Compared with the prior art, the method can effectively improve the hydrotreatment depth of the material oil; besides, the two hydrotreatment reaction areas only need one set of hydrogen circulating system; the device investment and the operation cost are low.

Description

technical field [0001] The invention relates to a hydrogenation treatment method, in particular to a method for deep hydrogenation treatment of low-quality heavy distillate oil by making full use of low-sulfur circulating hydrogen. Background technique [0002] At present, the nature of crude oil in the world is gradually becoming heavier and worse, coupled with the continuous development of the world economy and the increasingly stringent environmental protection regulations, it is necessary to produce a large amount of light and clean fuels. Cost to produce products that meet the requirements. [0003] Catalytic cracking (FCC) continues to play an important role in the processing of heavy feedstocks to produce light products. The quality of light oil products directly produced by catalytic cracking technology is poor, especially the sulfur content of catalytic gasoline is relatively high, the sulfur content and aromatic content of catalytic diesel are high, and the cetane...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10G67/02

Inventor 刘涛李宝忠曾榕辉石友良黄新露白振民张学辉

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com