Vacuum pump unit

一种真空泵、主泵的技术,应用在泵元件、泵、电气元件等方向,能够解决降低润滑性能、泵寿命缩短、管误连接等问题,达到避免过载和腐蚀、有效泵抽运行、防止误连接的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

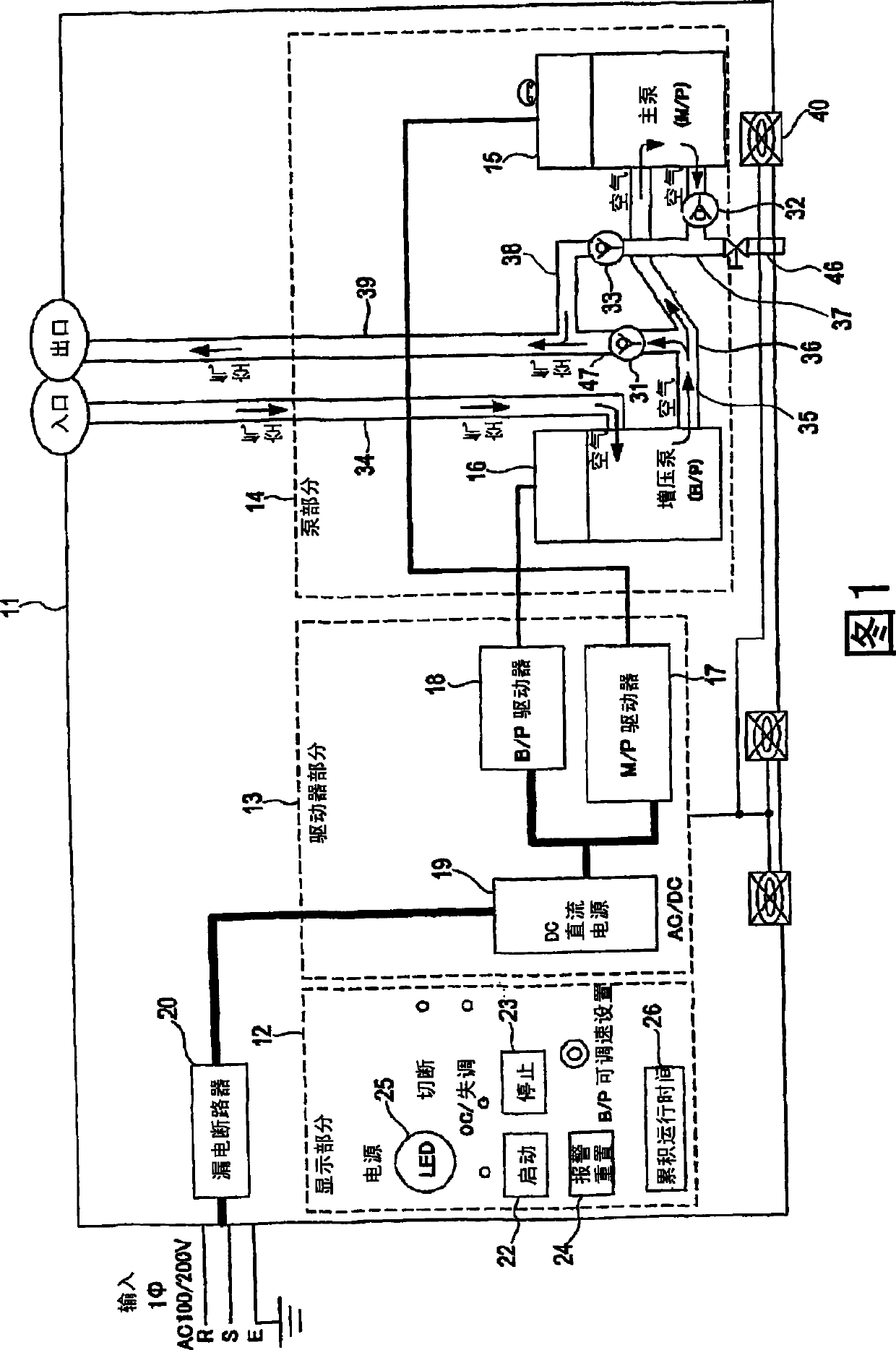

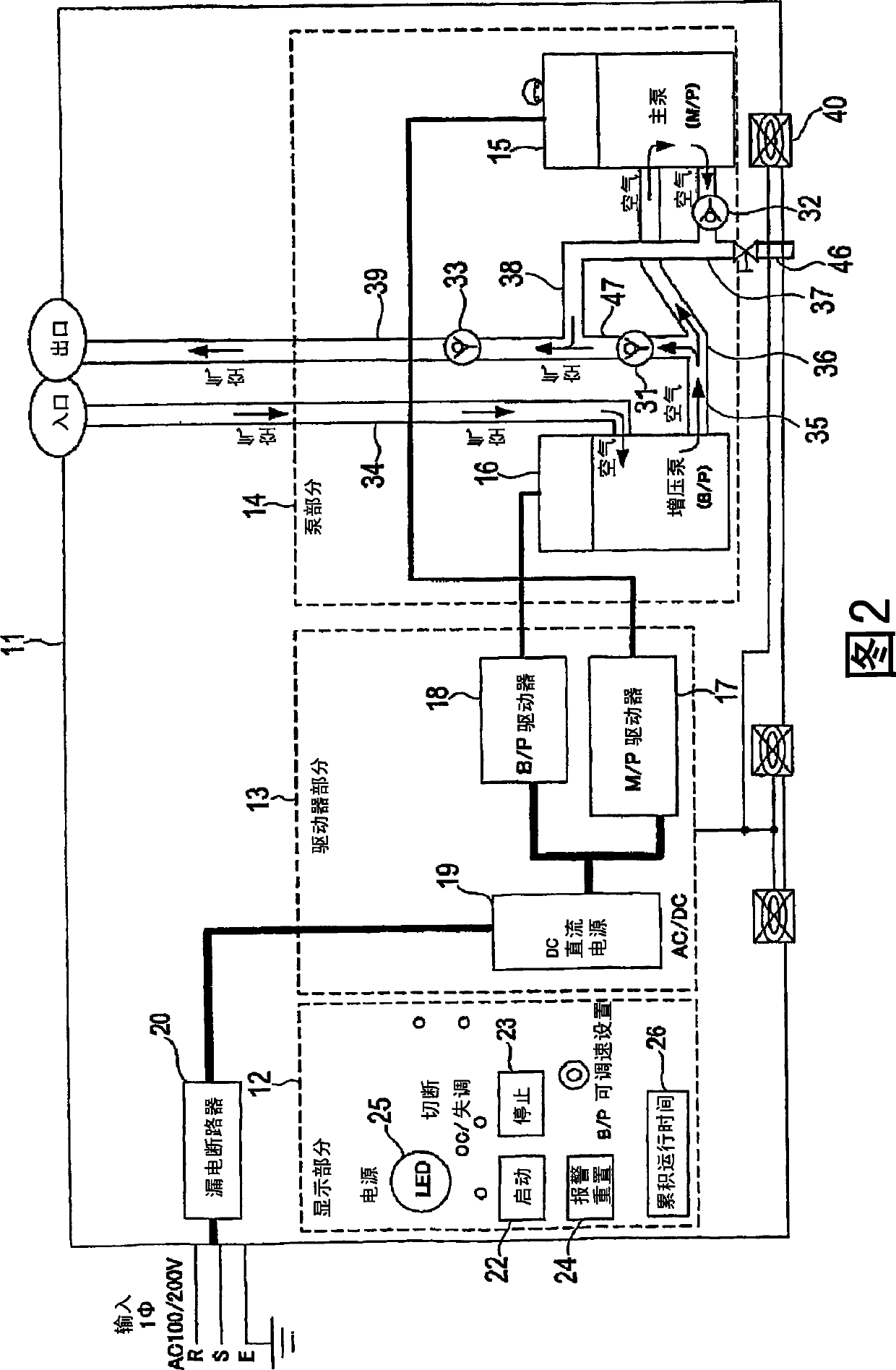

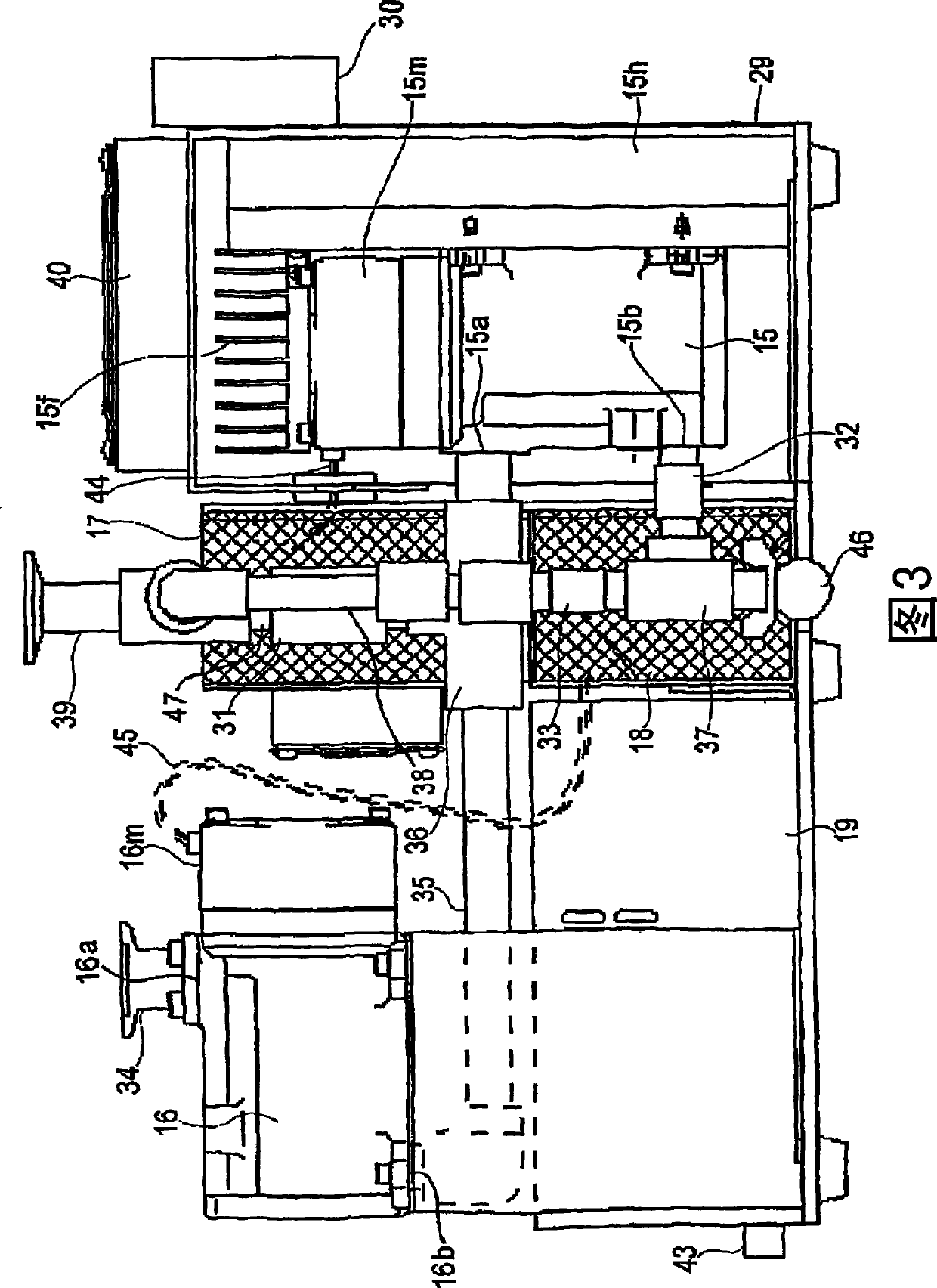

[0052] Embodiments of the present invention will be described below with reference to the drawings. The same or corresponding elements are denoted by the same reference numerals and will not be repeatedly introduced.

[0053] FIG. 1 is a schematic diagram showing a vacuum pump unit according to an embodiment of the present invention. FIG. 2 is a view showing a modified arrangement of valves shown in FIG. 1 . The vacuum pump unit 11 includes a display portion 12 , a driver portion 13 and a pump portion 14 . The pump section 14 includes two pumps, a main pump (rough vacuum pump) 15 and a booster pump 16 connected in series. These pumps have the same shape, same size and same displacement, ie, same structure. However, the main pump 15 and the booster pump 16 may have different structures.

[0054] Each of the vacuum pumps 15 and 16 is a two-shaft variable displacement screw pump that has no timing gears but uses a non-contact magnetic coupling that provides synchronous rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com