Single-mode optical fiber optimizing dispersion characteristic

A technology of single-mode fiber and dispersion characteristics, applied in the field of optical communication, can solve the problems of increased additional loss, increased reflection, etc., and achieve the effects of PMD performance improvement, balanced stress distribution, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

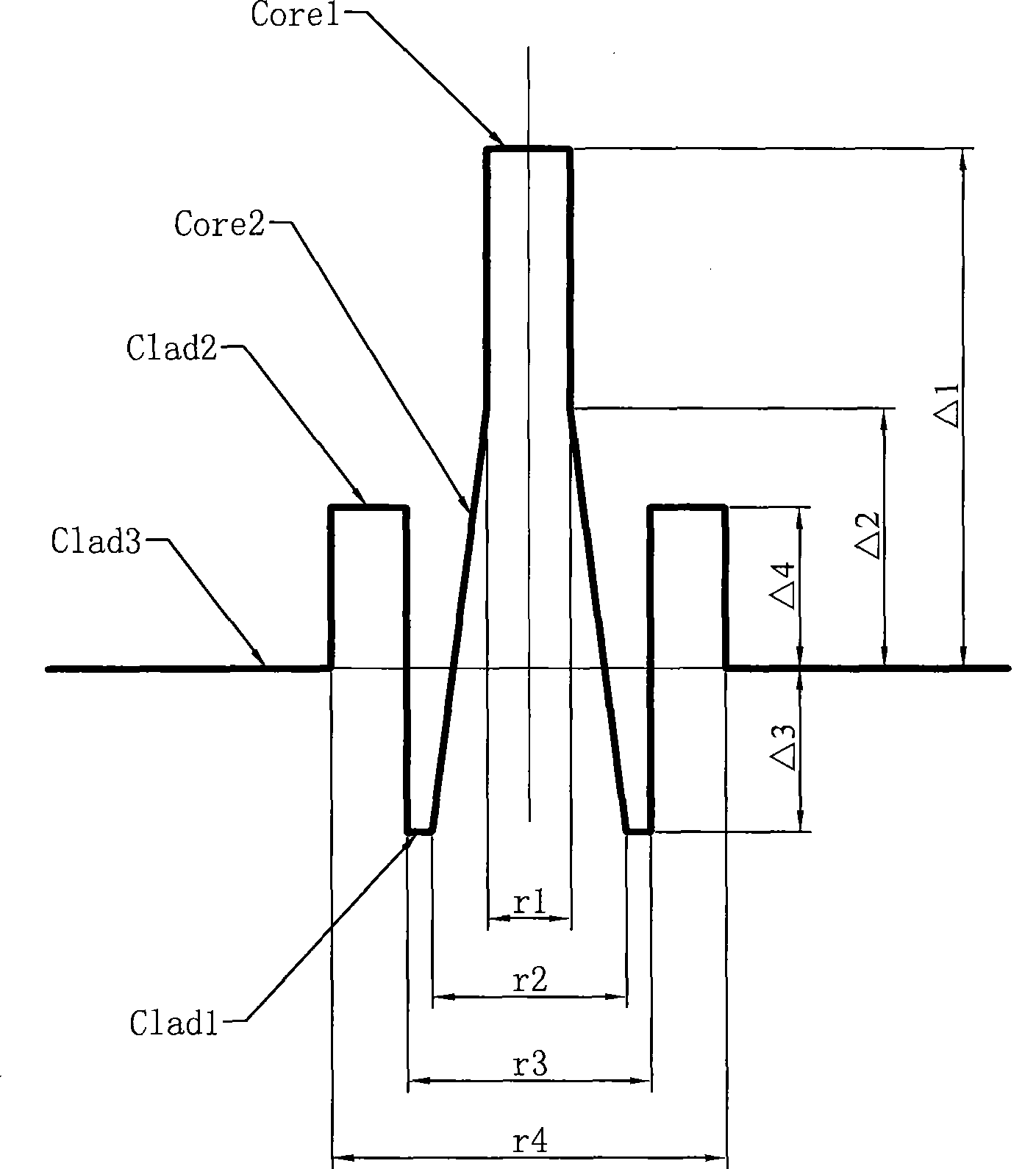

[0035] MCVD (modified chemical vapor deposition) process is used to manufacture the optical fiber core layer, and OVD (outside vapor deposition) process is used to manufacture the optical fiber cladding, according to figure 1 The shown optical fiber waveguide refractive index distribution curve, the following is a set of relative refractive index difference distribution parameters:

[0036] The parameters of the first core layer Core1 are: Δn1 is about 0.45%, r1 is about 6.0um,

[0037] The parameters of the second core layer Core2 are: Δn2 is about 0.35%, r2 is about 7.3um,

[0038] The parameters of the first cladding layer Clad1 are: Δn3 is about -0.14%, r3 is about 10.8um,

[0039] The parameters of the second cladding layer Clad2 are: Δn4 is about 0.12%, r4 is about 18.5um,

[0040] The outermost cladding is layered as a pure silica glass layer.

[0041] The properties of the resulting fiber are as follows:

[0042] 1550nm effective area: 58um 2 ,

[0043] Zero disp...

Embodiment 2

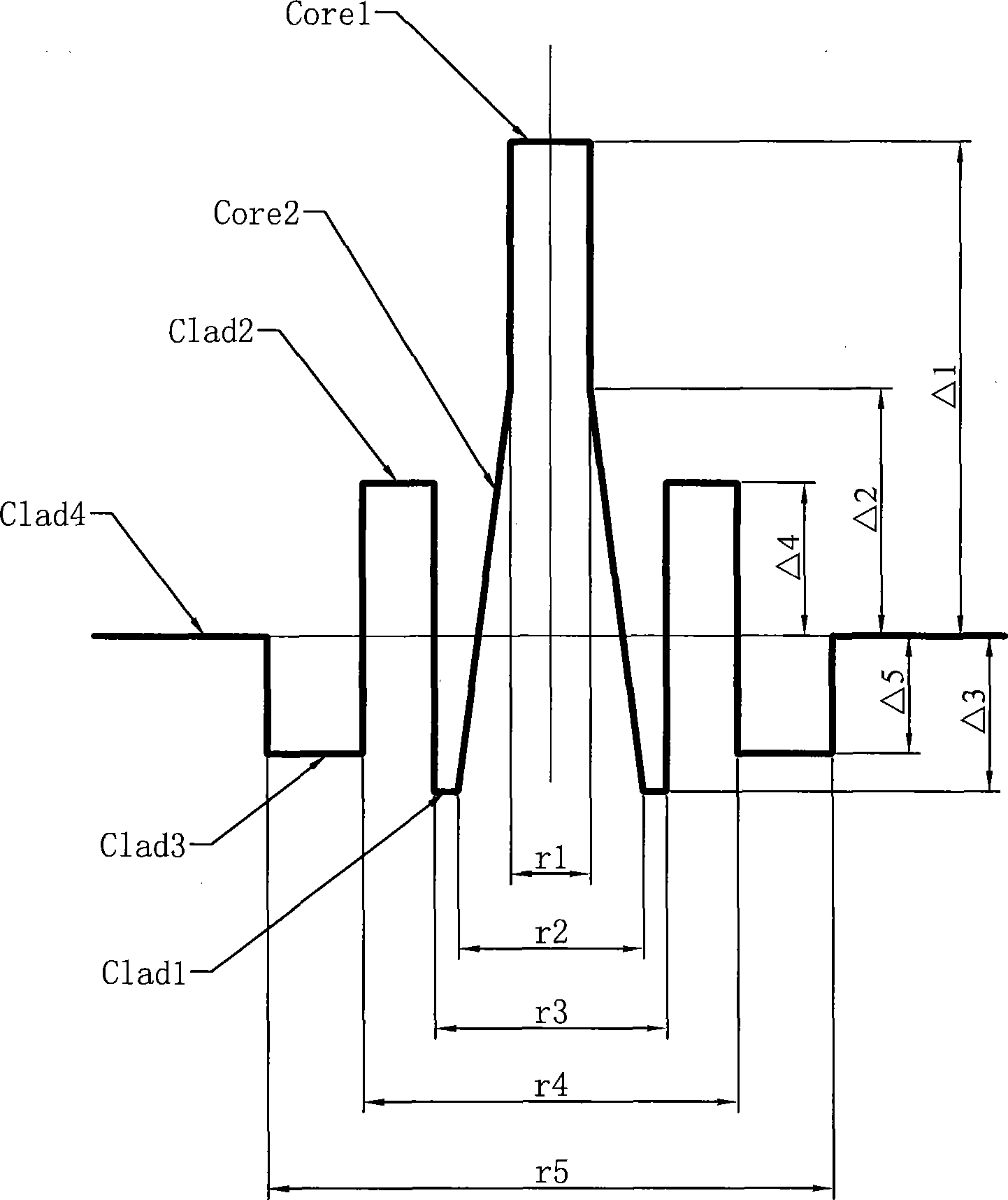

[0053] The optical fiber core layer is manufactured by plasma chemical vapor deposition (PCVD), and the optical fiber cladding is manufactured by OVD process, according to figure 2 The shown optical fiber waveguide refractive index distribution curve, the following is a set of relative refractive index difference distribution parameters:

[0054] The parameters of the first core layer Core1 are: Δn1 is about 0.44%, r1 is about 6.2um,

[0055] The parameters of the second core layer Core2 are: Δn2 is about 0.36%, r2 is about 7.3um,

[0056] The parameters of the first cladding layer Clad1 are: Δn3 is about -0.15%, r3 is about 10.8um,

[0057] The parameters of the second cladding layer Clad2 are: Δn4 is about 0.12%, r4 is about 18.5um,

[0058] The parameters of the third cladding layer Clad3 are: Δn5 is about -0.04%, r5 is about 28.5um,

[0059] The outermost cladding is layered as a pure silica glass layer.

[0060] The properties of the resulting fiber are as follows: ...

Embodiment 3

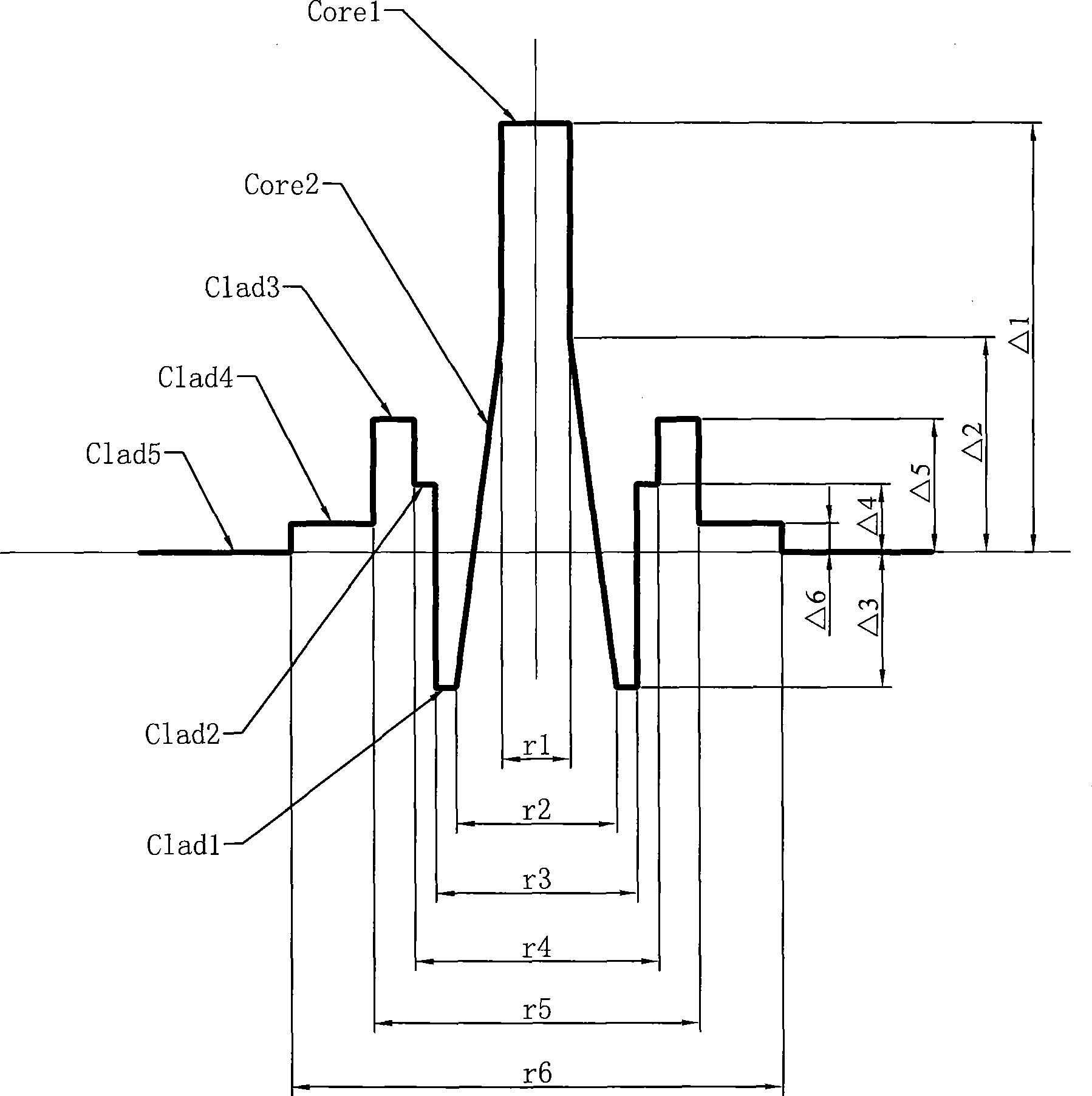

[0072] OVD process is used to manufacture the fiber core layer, and the OVD process is used to manufacture the fiber cladding, according to image 3 The shown optical fiber waveguide refractive index distribution curve, the following is a set of relative refractive index difference distribution parameters:

[0073] The parameters of the first core layer Core1 are: Δn 1 About 0.44%, r1 is about 6.0um,

[0074] The parameters of the second core layer Core2 are: Δn 2 About 0.35%, r2 is about 7.3um,

[0075] The parameters of the first cladding layer Clad1 are: Δn 3 About -0.15%, r3 is about 10.8um,

[0076] The parameters of the second cladding layer Clad2 are: Δn 4 About 0.06%, r4 is about 12.5um,

[0077] The parameters of the third cladding layer Clad3 are: Δn 5 About 0.12%, r5 is about 18.5um,

[0078] The parameters of the fourth cladding layer Clad4 are: Δn 6 About 0.01%, r6 is about 28.5um,

[0079] The outermost cladding is layered as a pure silica glass layer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com