Twin-fluid nozzle for cleaning substrate

A dual-fluid nozzle and dual-fluid technology, applied in the direction of liquid injection devices, cleaning methods and appliances, spraying devices, etc., can solve the problems of lower cleaning efficiency and inability to generate uniform-sized dual-fluid droplets, etc., to improve cleaning efficiency and stabilize pressure and flow, improve the effect of spray uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

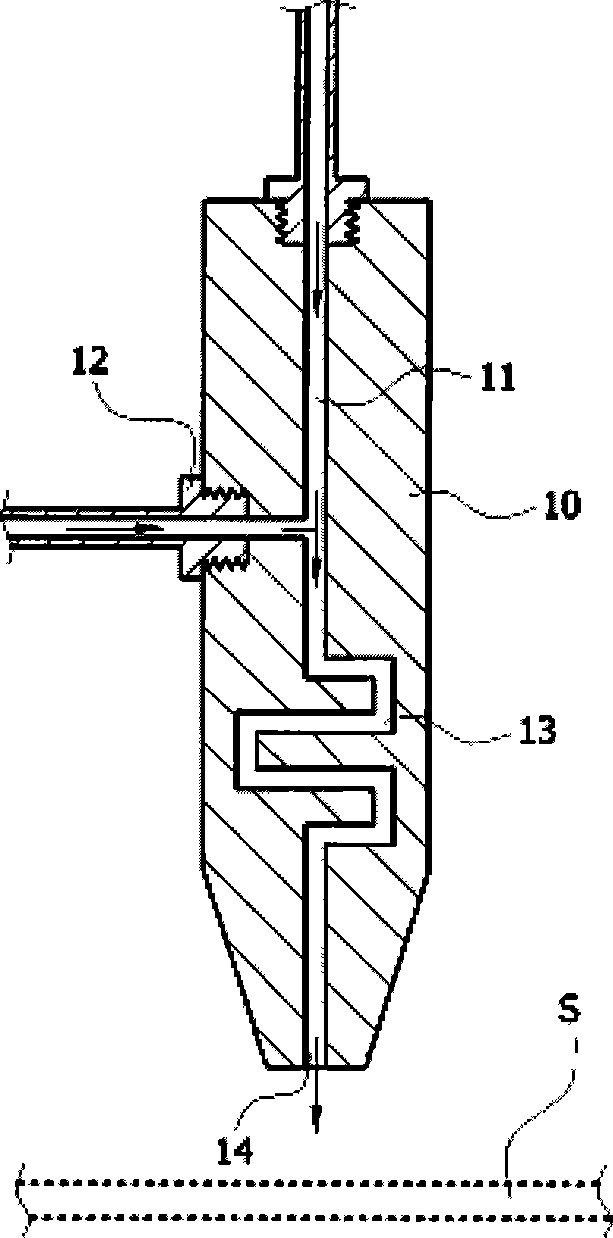

[0016] Hereinafter, preferred embodiments of the two-fluid nozzle for cleaning a substrate provided by the present invention will be described in detail with reference to the accompanying drawings.

[0017] figure 2 It is a cross-sectional view and a partially enlarged cross-sectional view of a dual-fluid nozzle for cleaning a substrate according to an embodiment of the present invention.

[0018] Such as figure 2 As shown, the dual-fluid nozzle for substrate cleaning provided by the embodiment of the present invention includes: a first housing part 100 and a second housing part 200 for respectively housing different fluids; The first injection port 111 for the first fluid; the second passage 210, which has the second injection port 211 for injecting the second fluid, and the dual-fluid discharge part 400, for injecting the dual fluid produced by mixing the first fluid and the second fluid. fluid.

[0019] The above structure will be described in detail as follows.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com