Apparatus on a combing machine for monitoring the noil percentage

A percentage, carding machine technology, used in fiber processing safety devices, combers, fiber processing and other directions, can solve problems such as inability to identify, and achieve the effects of simplified maintenance work, simple structure, and improved energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

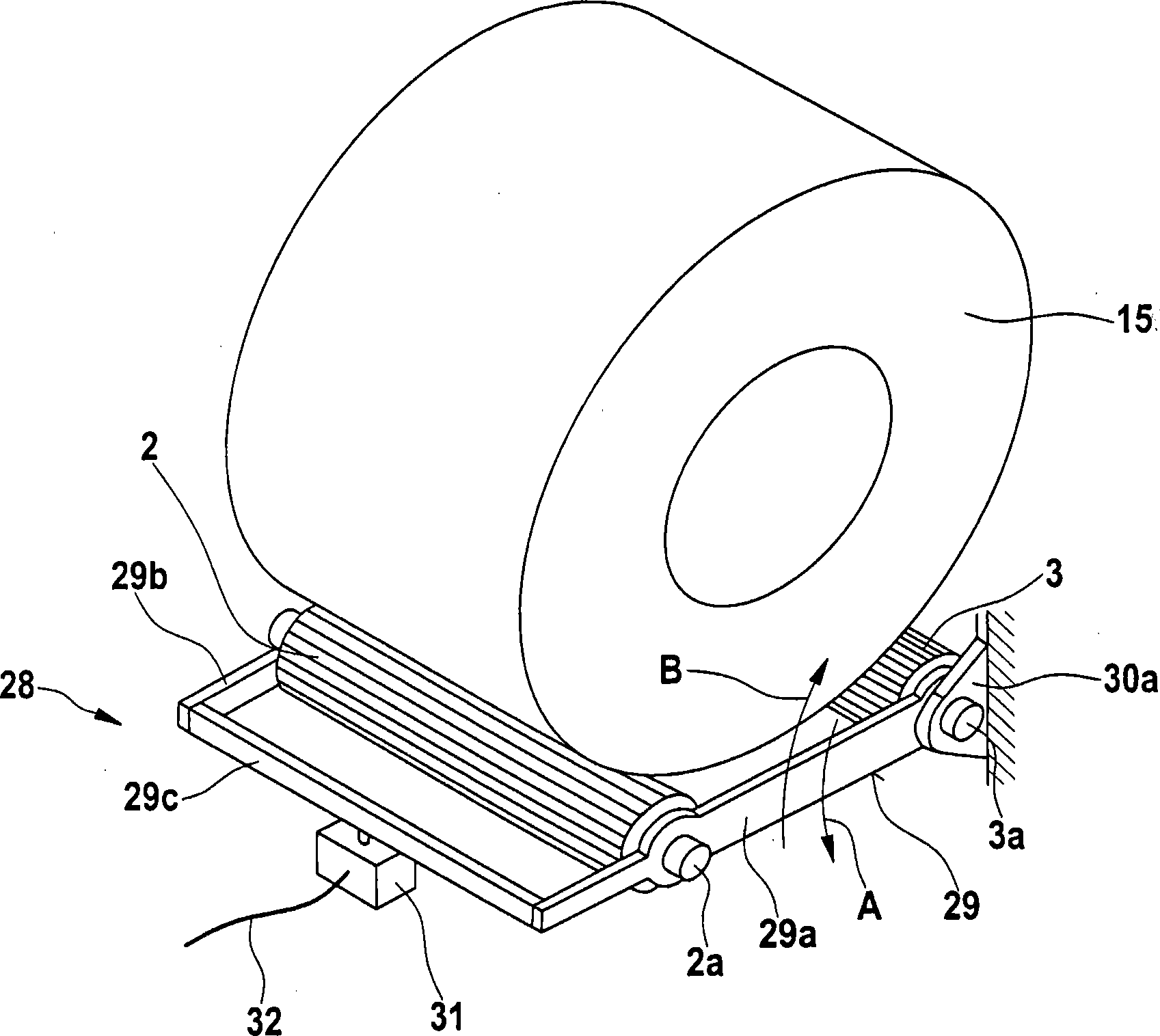

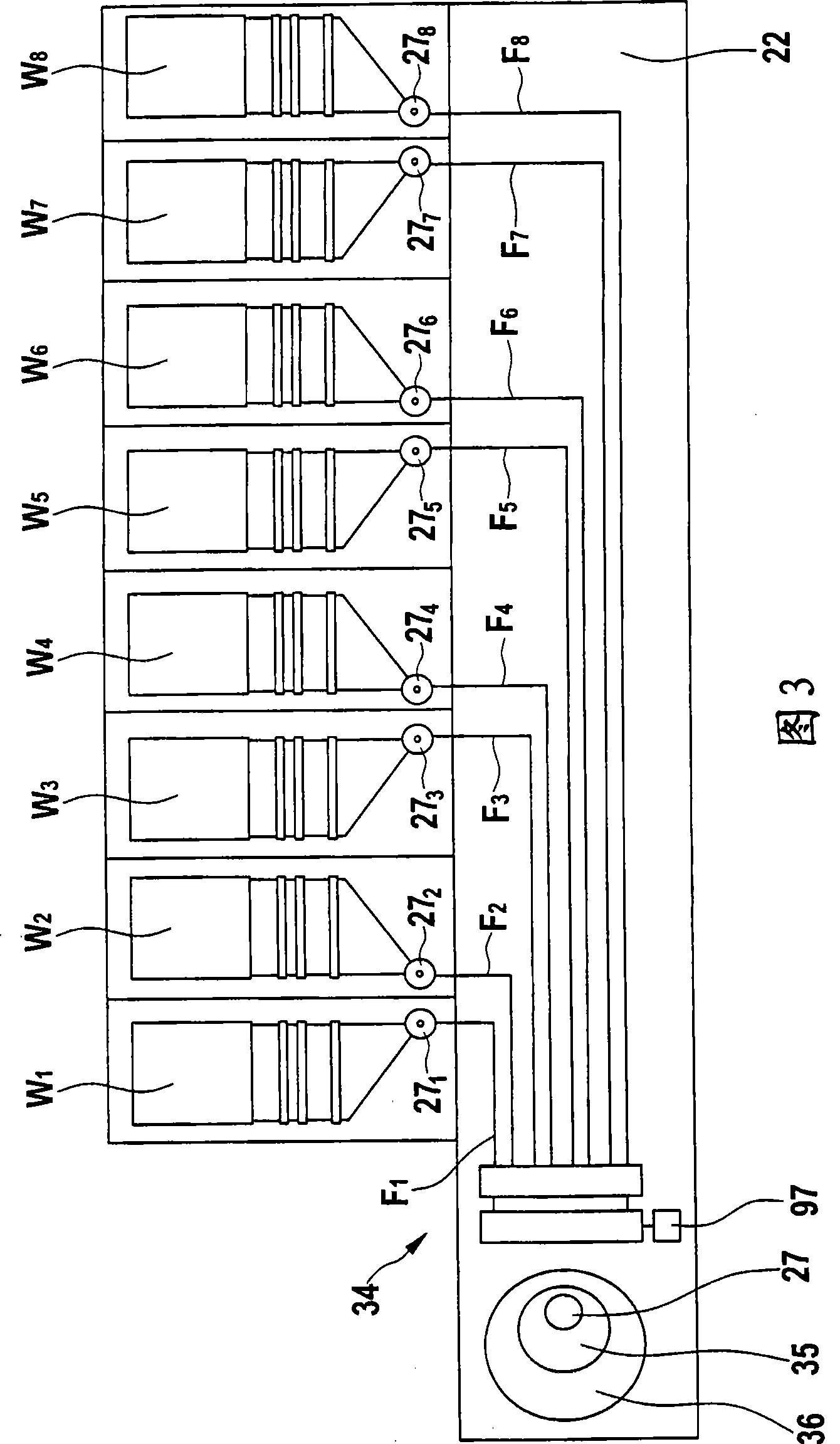

[0018] figure 1 The carding head K is shown, eight of which are installed on one carding machine. For the sake of clarity, this particular embodiment is shown and described with respect to only one carding head, each carding head having the illustrated features except for the common drive unit and sliver placement system. The carding head K comprises two fiber lap rollers 2 , 3 , the front fiber lap roller 2 is connected to a transmission 4 driven by an electric motor 5 . The fiber roll W rests on the fiber roll rollers 2, 3, and the fiber sheet 6 is unwound from the fiber roll by a rotary motion. The fiber sheet 6 is deflected at rollers 7 and conveyed to the feed roller 8 of the gripper assembly 9 . A press roller 12 mounted to pivot about a rod 10 under the bias of a spring 11 is arranged on a roller 7 , which is here likewise driven by a transmission 4 . The clamp 9 is arranged to be driven by reciprocating rods 13 , 14 driven by a shaft 15 connected to the drive mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com