Tyre expanding mechanism for X-ray tyre detecting machine

A detection machine and X-ray technology, which is applied to measurement devices, use of wave/particle radiation, material analysis using radiation, etc., can solve the difficulty of increasing the accuracy of control of the operating position of the tire support shaft, the complex structure, and the unstable operation. and other problems, to achieve the effect of simplified structure, stable operation and accurate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

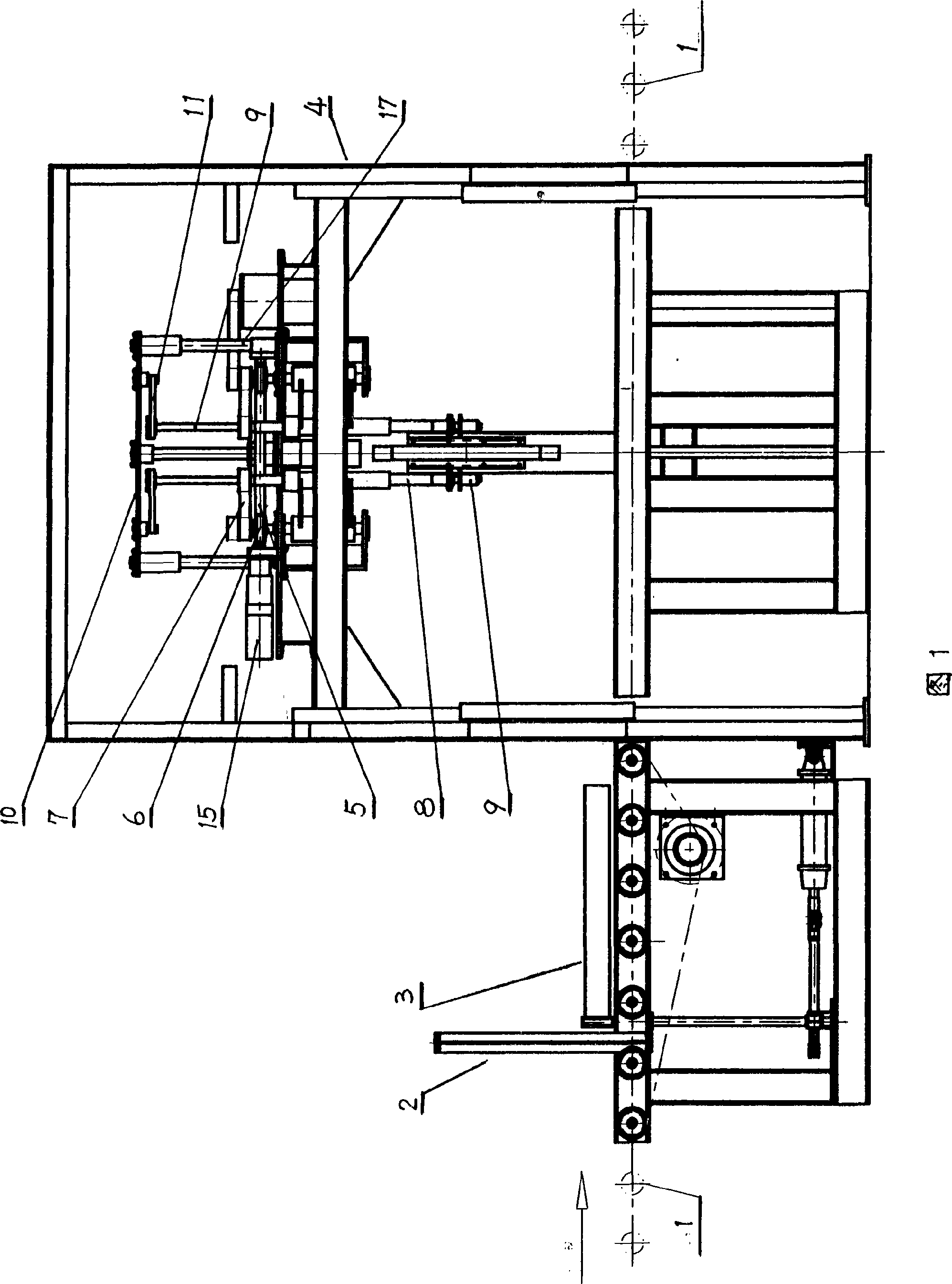

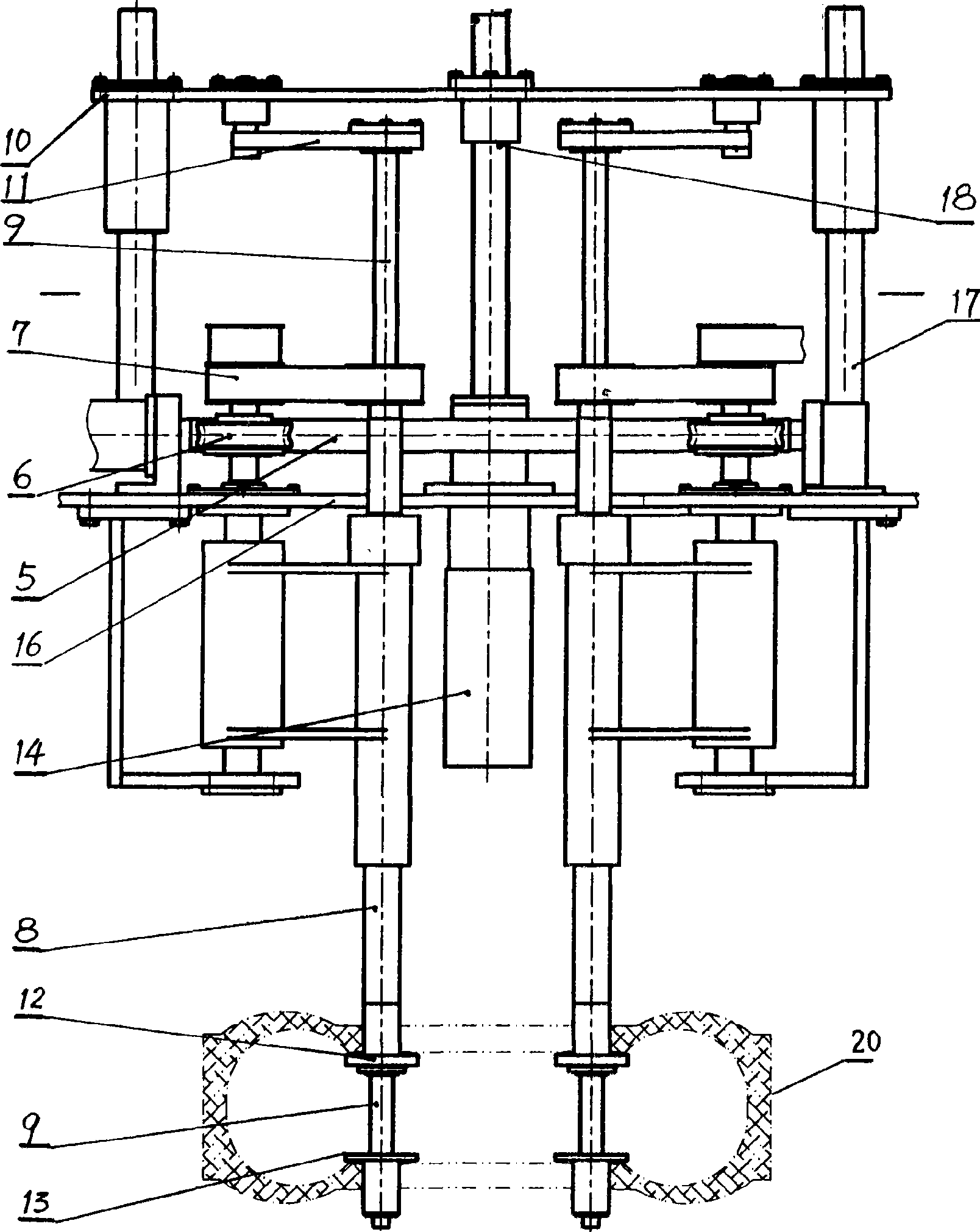

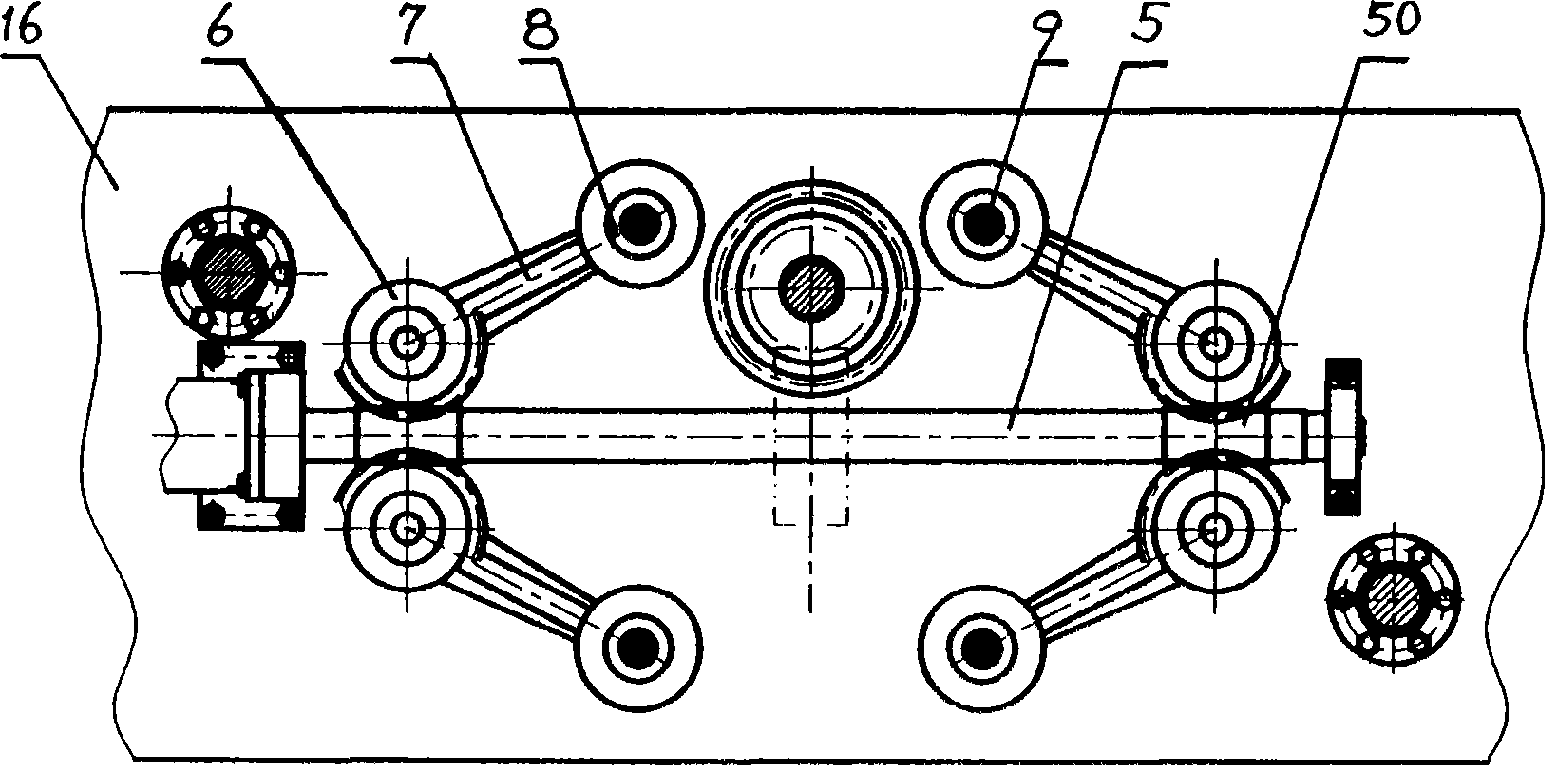

[0007] Figure 1 and figure 2 As shown, the X-ray tire inspection machine mainly includes a tire transmission part 1, a tire specification measurement part 2, a tire centering part 3, a tire expansion mechanism part 4, and an X-ray and imaging system part. In the figure, the X-ray and imaging system Some parts are omitted to fully demonstrate the tire expansion mechanism of this support. The X-ray tire inspection machine of the present invention supports the tire expansion mechanism, and the specific implementation structure of its main body is as follows: image 3 As shown, the mechanism is two sets of symmetrical worm and gear transmission parts driven coaxially. Two worm gears 6 are arranged symmetrically on both sides of the two worms 50, and the tire support arm 7 and the worm gear 6 assembled with the tire support shaft 8 are fixedly arranged and formed on the worm 50, which is also a tire support part symmetrical to the center line of the axis 5. Figure 1, figure 2 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com