Adapter gear box in pre-control

A gearbox and pre-control technology, which is applied to vehicle gearboxes, bicycle gear shifting mechanisms, bicycle accessories, etc., can solve the problems of heavy gearbox weight, unsmooth shifting operation, and inability to meet various needs of operation modes, etc. Compact structure and weight saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

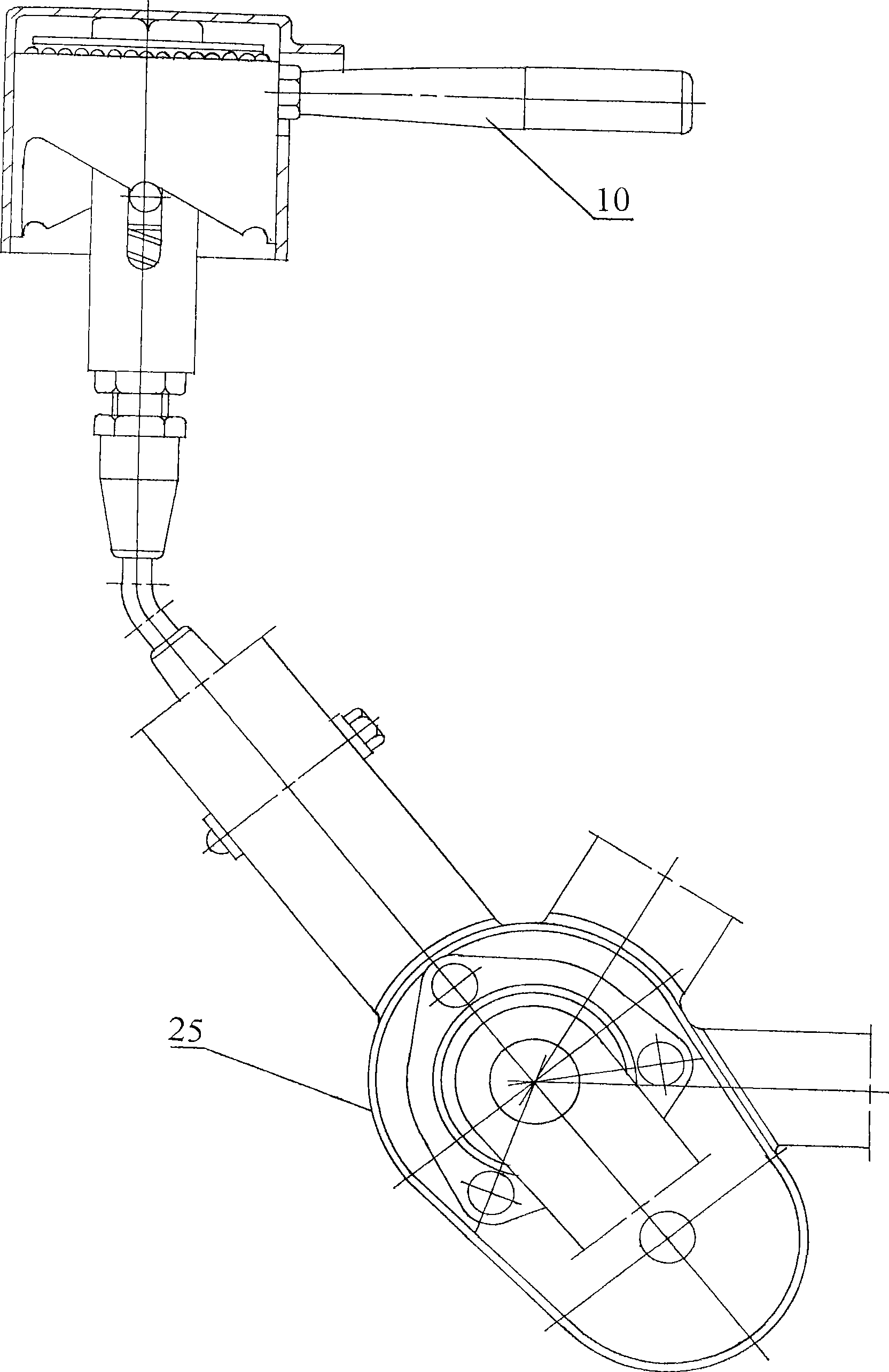

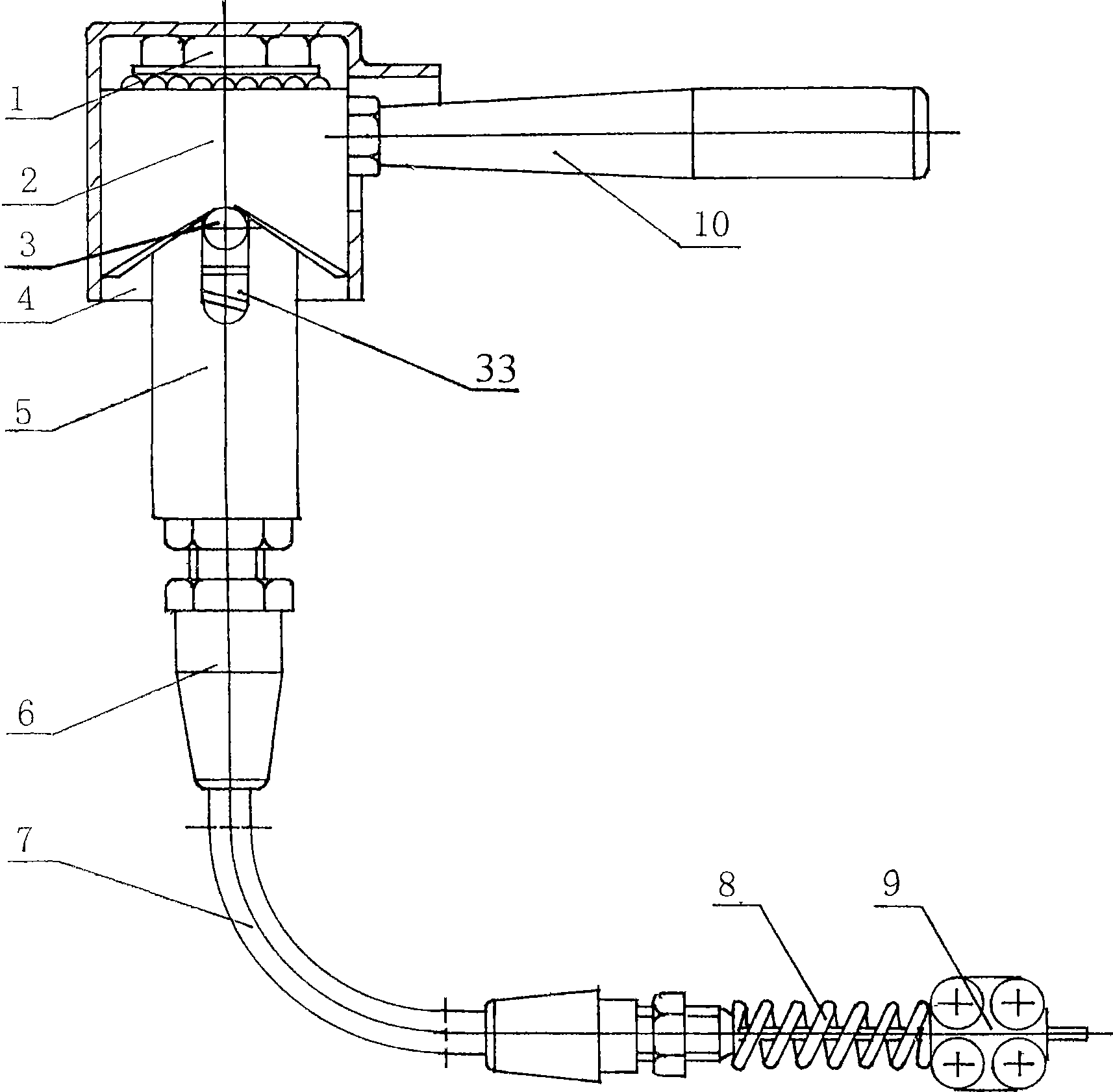

[0022] see image 3 , Figure 4 , Figure 7 , present embodiment comprises controller and gearbox, and controller is installed on the handlebar of bicycle or tricycle, or the position that other wants to install, and it comprises operating rod 10, protective cover 4, standpipe 5 and wire clip 9, in protective A spinning ring 2 is installed in the cover 4 through a nut 1 , and an operating rod 10 is connected to the spinning ring 2 . There is a U-shaped groove 33 at one end of the standpipe 5, and there is a slider 12 at one end of the U-shaped groove in the standpipe. . The other end of standpipe 5 connects guide tube 7 by leather sheath 6, connects small spring 8 at the other end of guide tube 7, and the other end of little spring 8 connects wire clip 9, and one end of slide block in standpipe 5 connects steel wire 34 and Surrounding the large spring 13 outside the steel wire, the steel wire 34 passes through the conduit 7 and the small spring 8 to be connected to the lin...

Embodiment 2

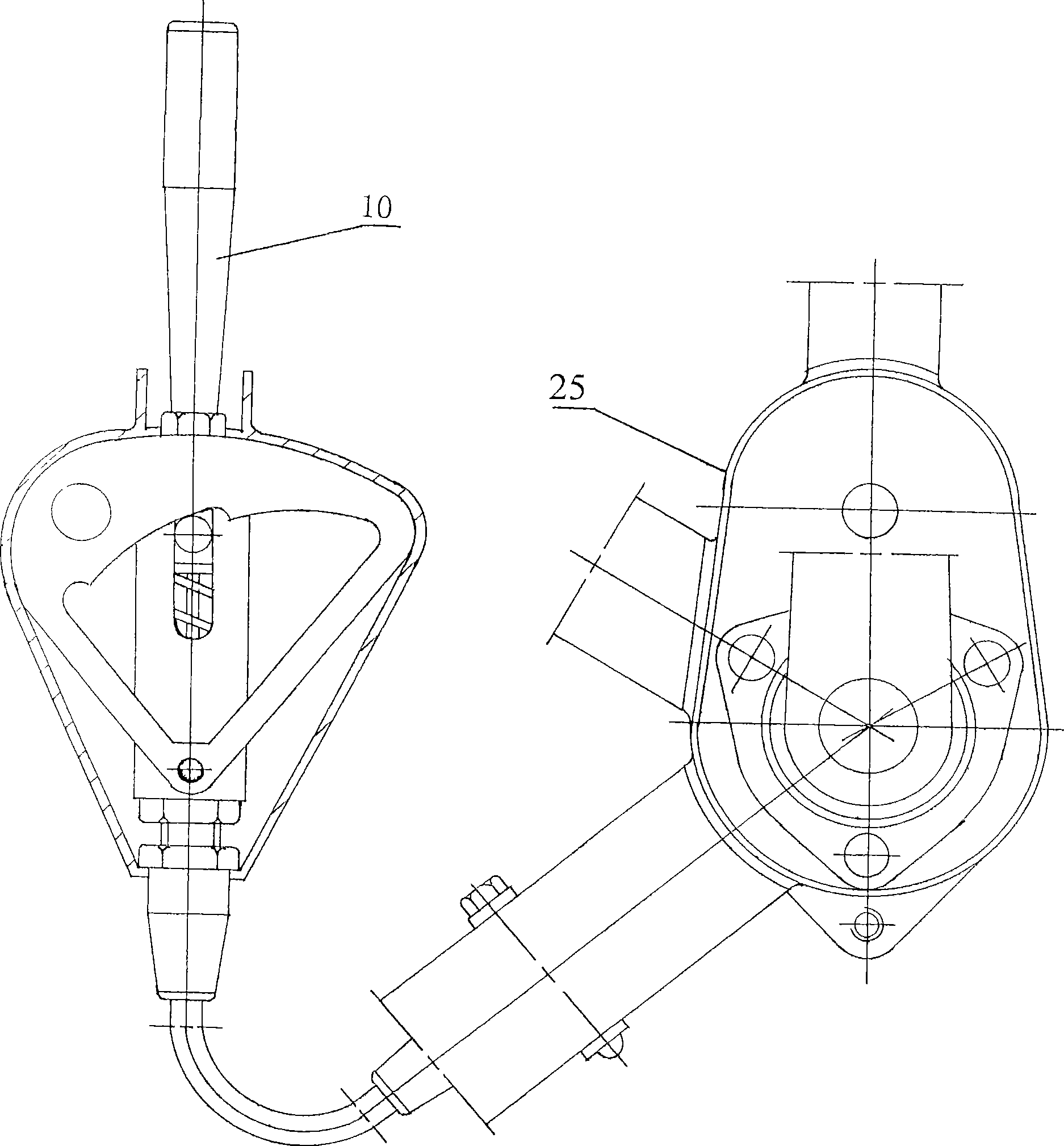

[0024] see Figure 5 , Figure 6 , Figure 7 , the controller of this embodiment is a Shunba two-speed controller, and the other structures are the same as those of Embodiment 1. The operating rod 10 of the controller is connected to the top of the spinning ring 2 , the lower end of the spinning ring 2 is connected to the lower end of the standpipe 5 through a pin 15 , and the protective cover 4 is covered on the lower end of the standpipe 5 .

Embodiment 3

[0026] see figure 1 and Figure 8 , the gearbox of this embodiment is a three-speed gearbox. Compared with Embodiment 1, a three-tooth reverse gear 23 is installed on the rear axle 24 through a rear needle bearing 31, and there is one more middle gear than the two-speed reverse gear. Teeth 32, constitute a three-speed gearbox with left, middle and right gears (see Figure 8 ). The controller is a three-speed handlebar controller, and the spinning ring of the three-speed controller is one more step than that of the two-speed controller (see figure 1 ). Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com