Method of preparing electronic device case

An electronic device and manufacturing method technology, applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, layered products, etc., can solve the problems of diffusion or volatilization, affecting the aesthetics of graphics, and smudged edges of graphics on the shell, etc. Simplify the manufacturing process, omit the paint baking process, and avoid the effect of edge stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

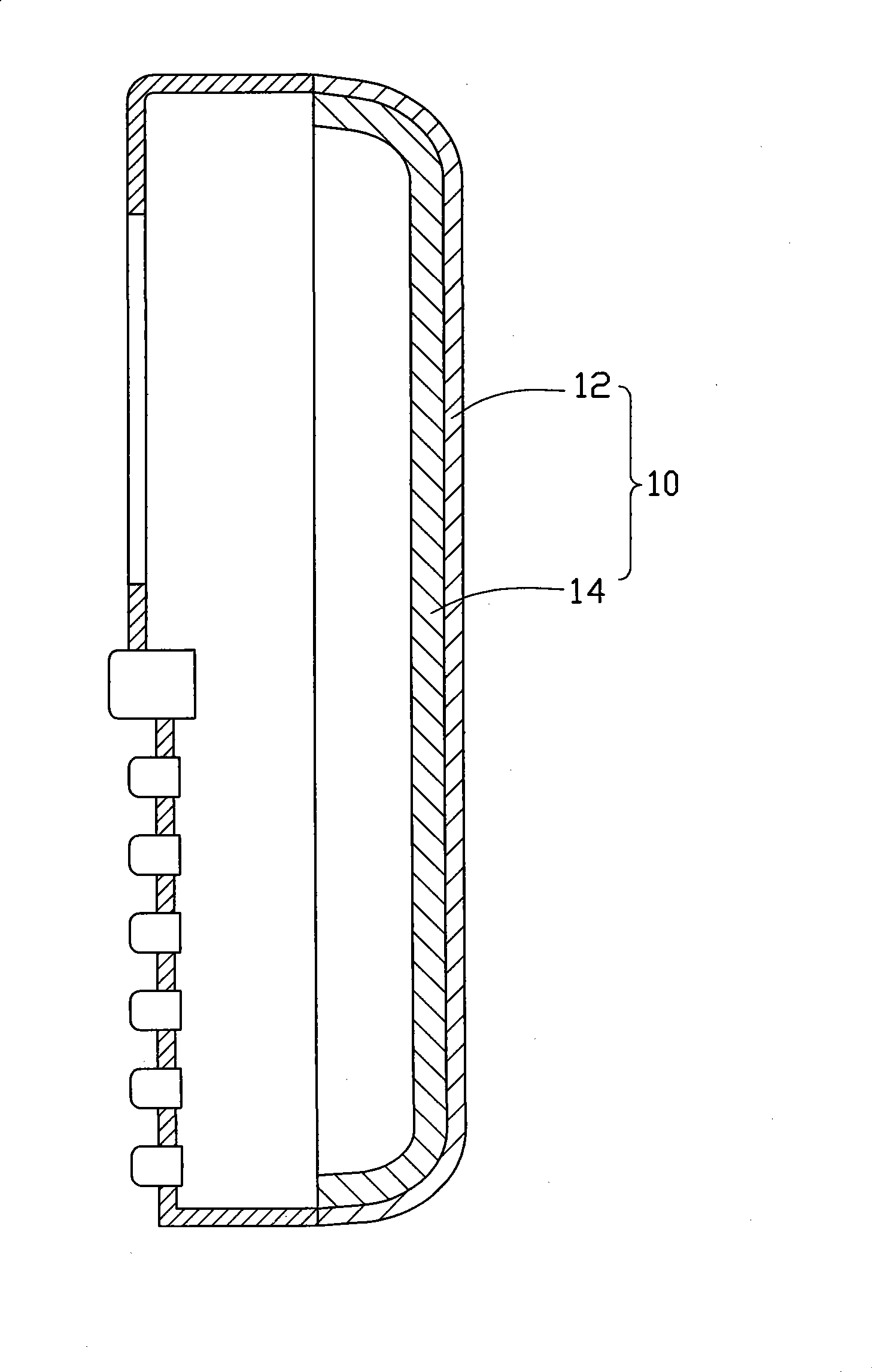

[0017] see figure 1 , shows an electronic device case 10 according to a preferred embodiment of the present invention, the case 10 includes a thin film layer 12 and a base body 14, the thin film layer 12 and the base body 14 are integrally formed and the thin film layer 12 is positioned on the base body 14 The outer layer, the film layer 12 is used to decorate the surface of the housing 10.

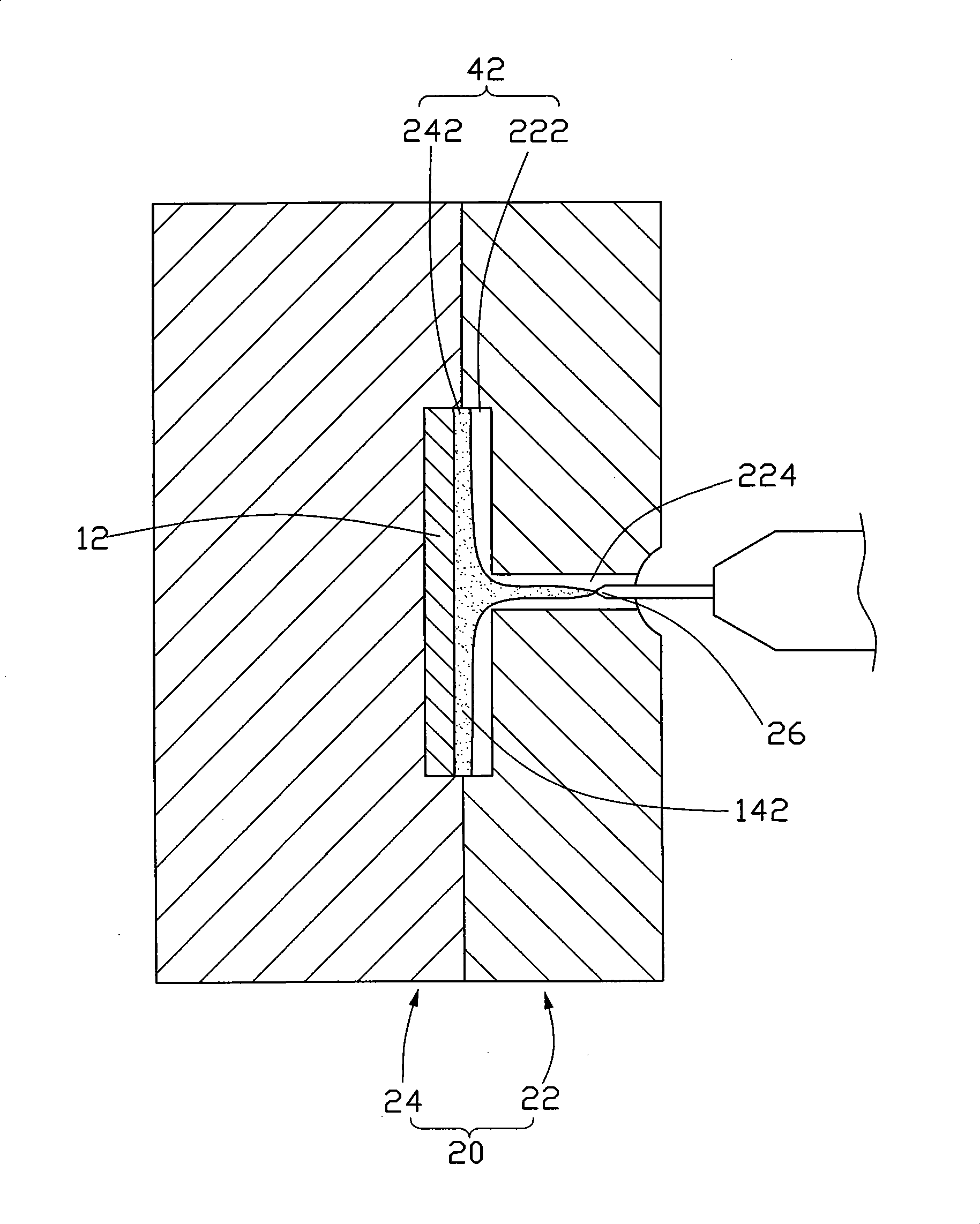

[0018] see figure 2 , the thickness of the film layer 12 is relatively thin, it has high temperature resistance, and its melting point is higher than the melting point of the material of the substrate 14, and can be selected from materials such as plastics, glass, ceramics, alloys, etc., which can be formed as transparent or The outer layer of the housing 10 is non-transparent. A pattern 122 is printed on the film layer 12 .

[0019] The base 12 constitutes the main component of the housing 10, which is selected from more common injection molding resins, such as: polyvinyl chloride, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com