Shaper for dust-free paper production line

A production line, dust-free paper technology, applied in applications, household components, household appliances, etc., can solve the problems of uneven thickness of paper, white lumps, etc., and achieve uniform thickness of paper, increase adjustability, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

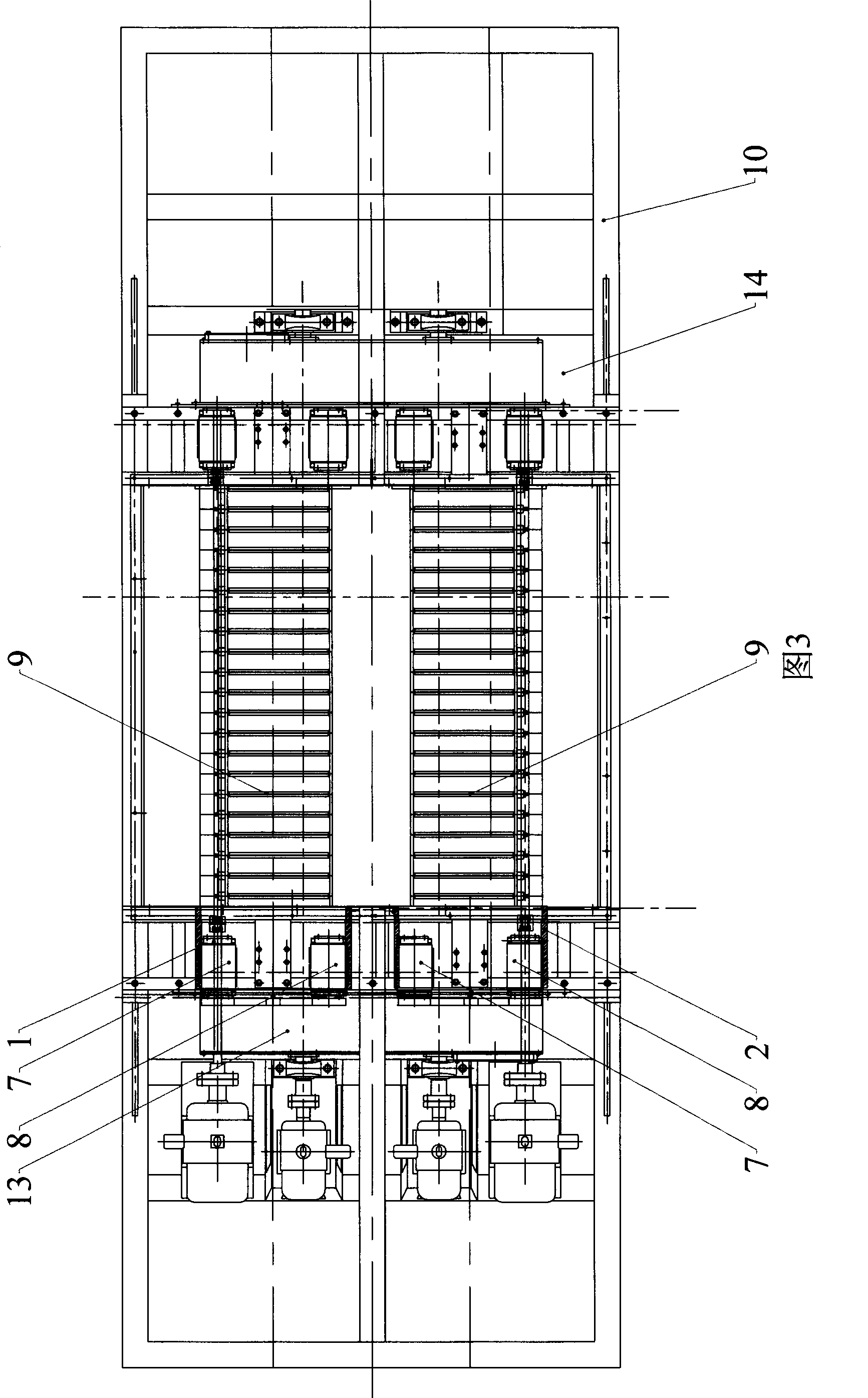

[0014] Referring to Fig. 1 to Fig. 3, Fig. 2 of this embodiment can best reflect the structural characteristics of the present invention. This embodiment includes a pair of sieve drums that rotate in half. The left and right ends of the drum are equipped with air guide enclosures, the upper part of the screen drum is supported and connected by the pressure roller 6, the lower part of the screen drum is connected by the transmission of the supporting rollers 7 and 8, and the air guide enclosures are the air guide enclosures of the vertical forming net. Plate 5, the air guide enclosure 5 of the vertical forming net is arranged inside the forming frame 10, and the lower end of the air guide enclosure 5 of the vertical forming net is supported by the sealing roller 11 of the forming frame; the screen drum includes clockwise The rotating left screen drum 1, the right screen drum 2 rotating counterclockwise; The second fiber breaker 4 rotating in the clockwise direction; above the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com