Plant breeding substrate and production method thereof

A cultivation substrate and plant technology, applied in the field of soilless cultivation substrate, can solve problems such as excessive burden on buildings, achieve the effects of reducing specific gravity, good ventilation, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

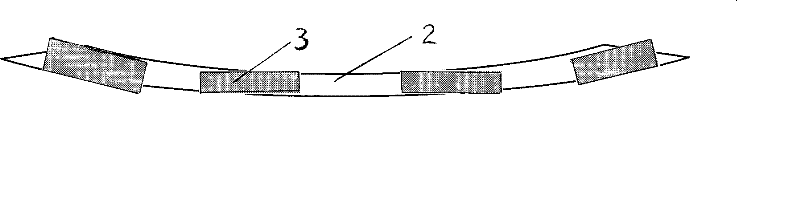

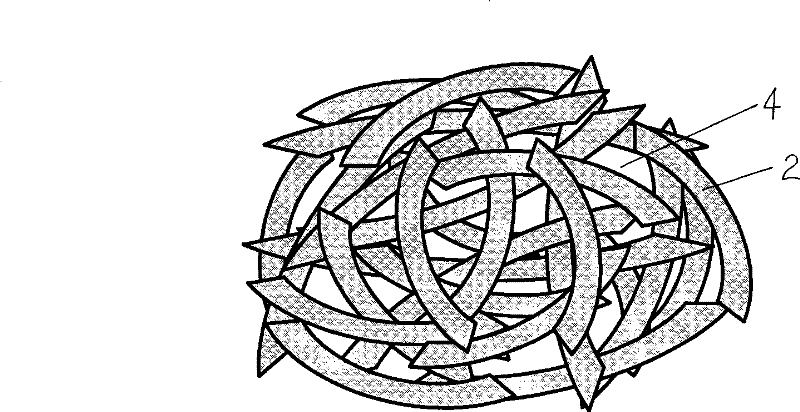

[0019] Such as figure 1 The plant cultivation substrate shown is the block plant cultivation base 1, and the raw material and volume ratio are: 94.3% of arcuate flake shavings wood fragments with a length of 5mm; 2.9% of adhesive; 1.8% of soil conditioner charcoal particles; nutrient particles body 0.09%; water 0.91%, the surface part of the wood chip 2 is coated with the adhesive 3, and the structure after coating the adhesive is as follows figure 2 As shown, the wood fragments are then joined by adhesive points, such as image 3 As shown, it has uniform voids 4 to ensure good air permeability and water storage. If all adhesives are applied, it will be as Figure 4 As shown, the air permeability and water storage are slightly poor, which affects the growth of plants. The matrix blocks connected by the above points are heated and fired to form an integrated matrix, and soil amendments and nutrient particles are uniformly arranged in the matrix. The best shape is a cuboid wi...

Embodiment 2

[0021] According to the method described in Example 1, the plant cultivation substrate is prepared, and the raw materials and specific volume percentages are as follows: Figure 5 The shaving length shown is 90% of linear flake shaving woody chips of 6 mm; binder 2.5%; soil conditioner porous ceramic particles 1.5%; nutrient granules 0.5%; water 5.5%.

Embodiment 3

[0023] According to the method described in Example 1, the plant cultivation substrate is prepared. The raw materials and specific volume percentages are: 96% of arcuate flake shaving wood fragments with a length of 4mm; 2% of adhesive; 1.05% of soil improver porous ceramic particles; nutrient granules 0.05%; water 0.90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com