Electric lamp with an outer vessel and a built-in lamp and method for production of same

An embedded, electric lamp technology, applied in discharge lamps, gas discharge lamps, gas discharge lamp parts, etc., can solve problems such as high cost, damage to appearance, damage to outer bulbs, etc., to reduce this force, avoid shadows, good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

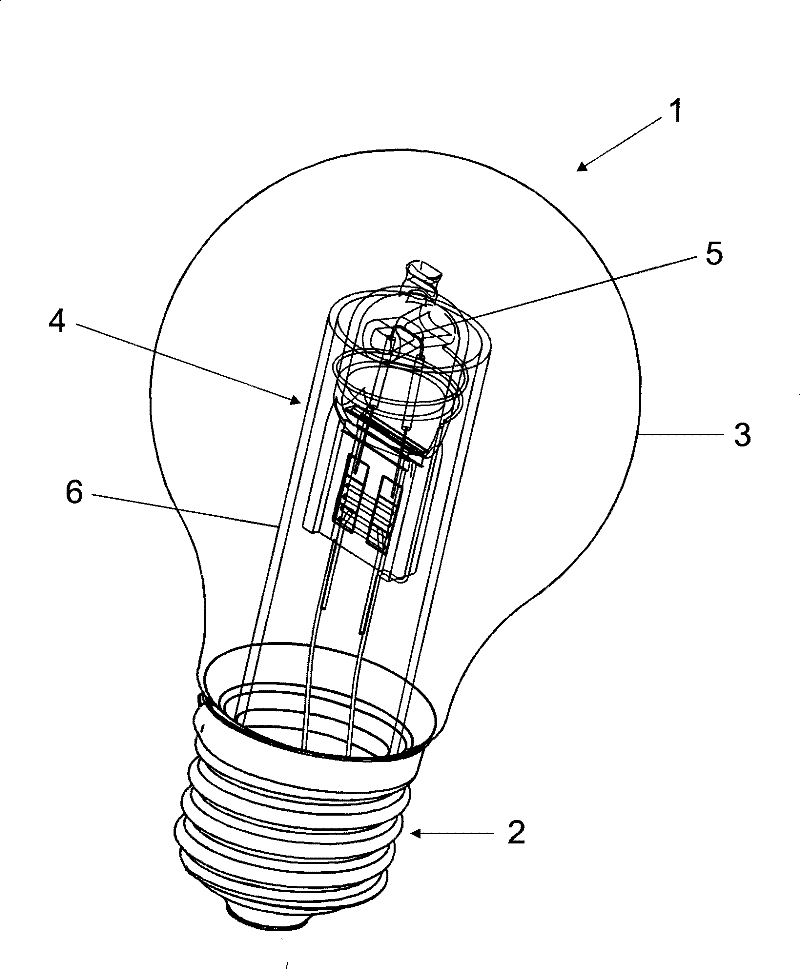

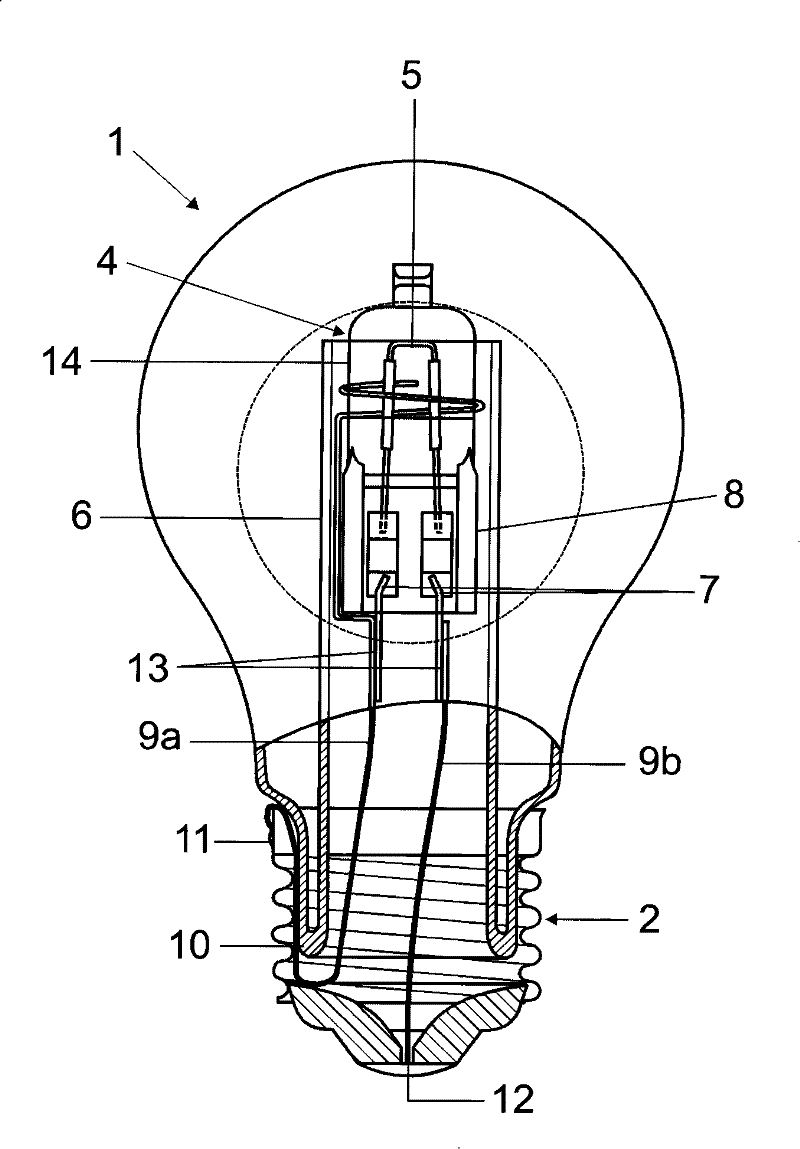

[0057] figure 1 A perspective view of a lamp 1 according to the invention is shown. The outer bulb 3 of type A55 is held in a lamp base 2 of type E27 which is common on the market. The built-in lamp 4 is arranged inside the outer bulb 3 such that the incandescent filament 5 of the built-in lamp 4 is located approximately within the outer bulb 3 at the position in which the incandescent filament is likewise arranged in a conventional incandescent lamp. The built-in lamp 4 is implemented as a so-called high-pressure halogen lamp using bulb extrusion technology, and such high-pressure halogen lamps are already known from the prior art. Furthermore, there is a cylindrical bulb 6 which surrounds the integral lamp 4 at most approximately its entire length and extends as far as the lamp base 2 .

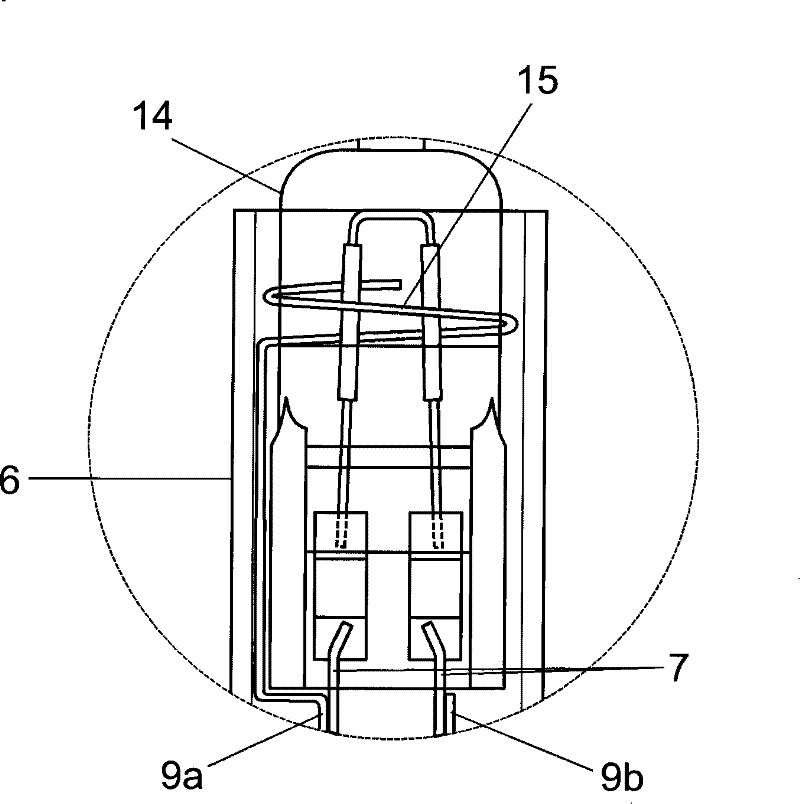

[0058] Details of the structure are available at figure 2 is particularly clearly seen. The incandescent filament 5 of the built-in lamp 4 is connected to a feeder 7 which protrudes fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com