Lagged type sensor for breaking when cover opening

A technology of opening the cover and power off, sensor, applied in circuits, electrical switches, electrical components, etc., can solve the problems of complex structure, can not be used for equipment modification, etc., to ensure production safety, facilitate on-site installation and use, and avoid violations or misoperations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

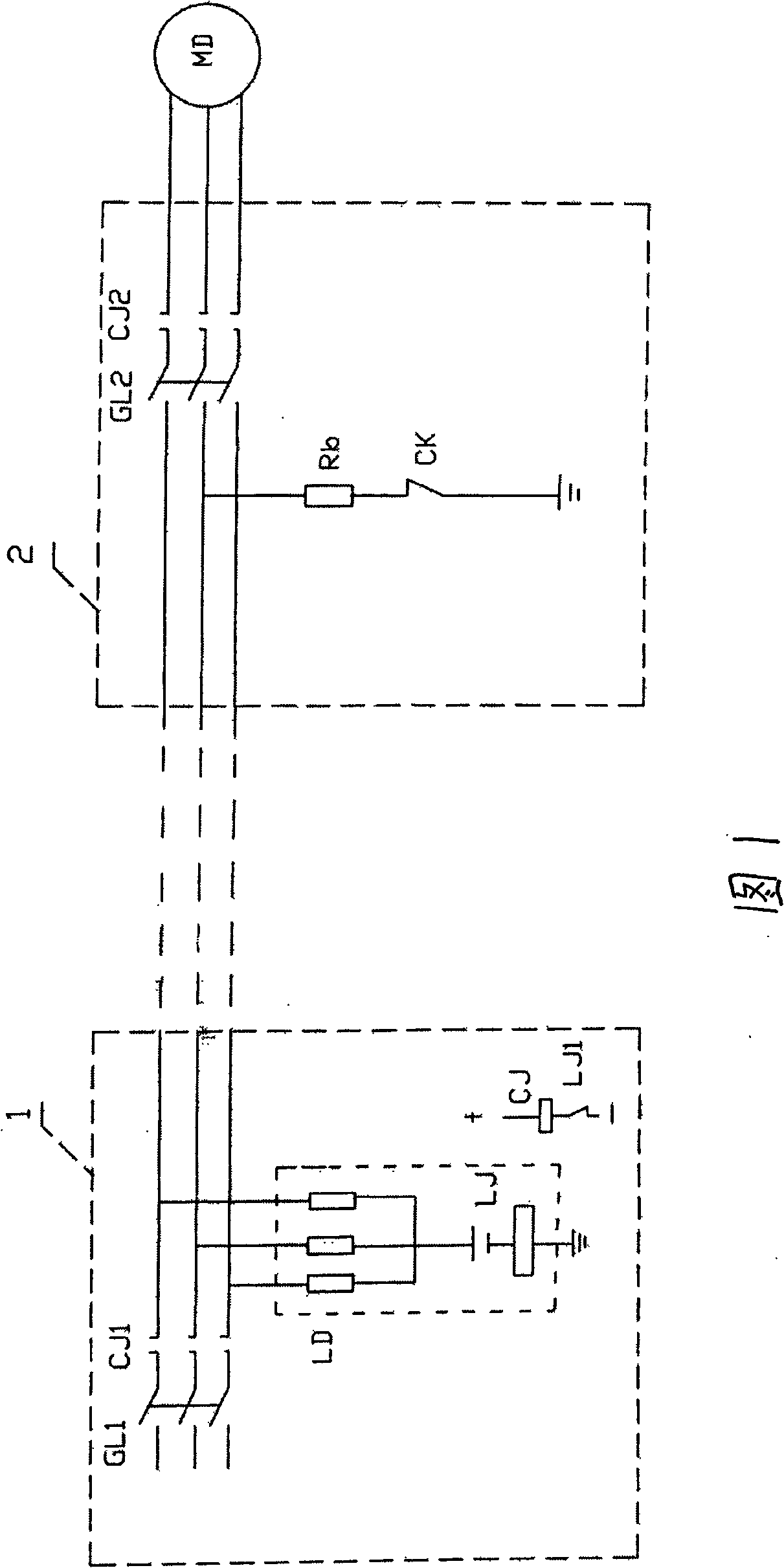

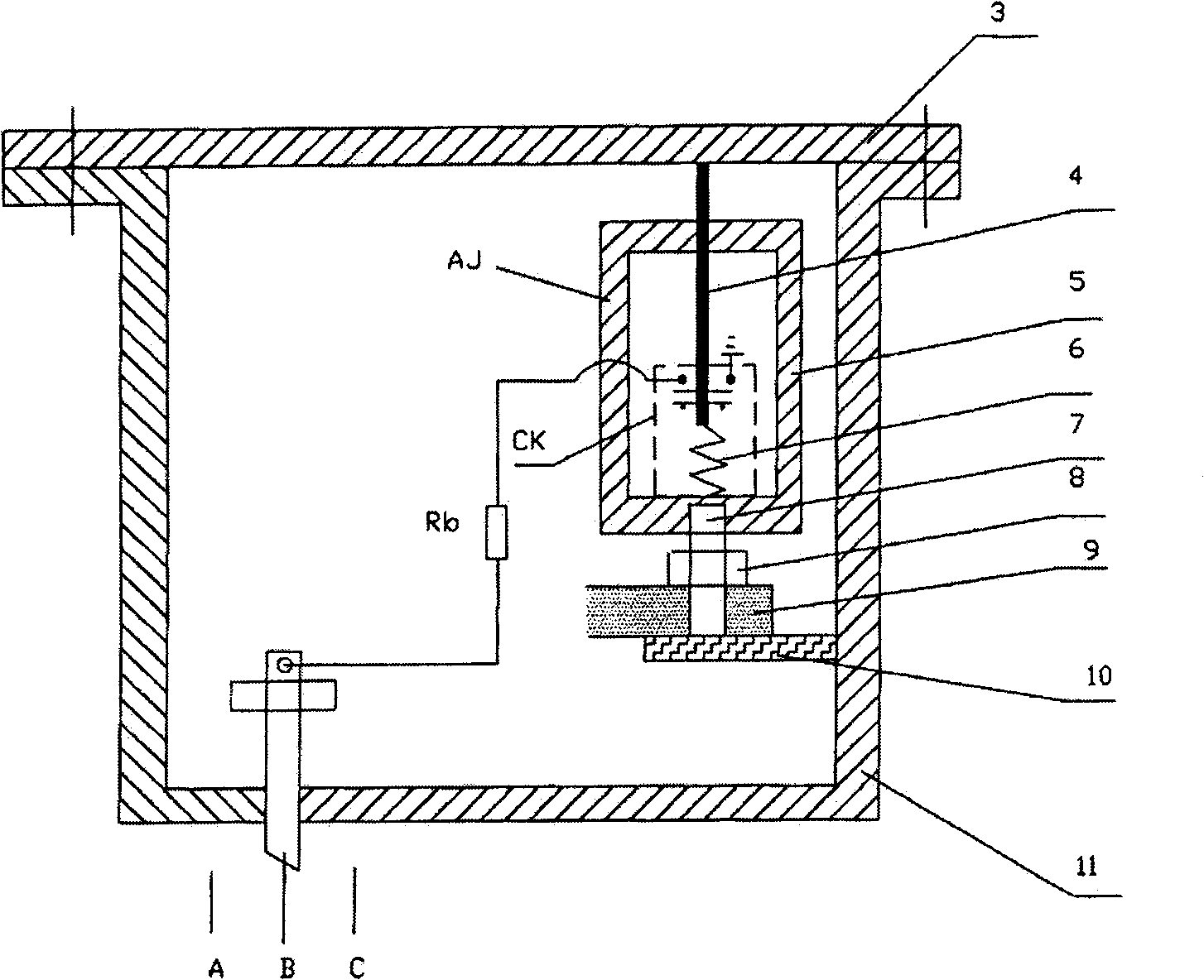

[0013] Figure 1, figure 2 The hysteresis-type cover-opening power-off sensor shown includes electrical components such as a disconnector GL, a leakage protector LD, a leakage relay LJ, a contactor CJ, and a junction box 11; The sensor AJ and the contact of the sensor button switch CK are connected to one end of the blocking resistor Rb, the other end of the blocking resistor Rb is connected to a certain phase on the power supply side of the isolation switch GL2, and the other end of the sensor button switch CK contact is grounded.

[0014] The sensor AJ is composed of a casing 5 , a button switch CK encapsulated in the casing 5 , a spring 6 , and a sensor rod 4 . The top of the sensor rod 4 is in contact with the upper cover 3 of the junction box 11 , and the bottom of the sensor rod 4 is equipped with a spring 6 . Components such as button switches can be replaced by touch switches, photoelectric and other non-contact switches.

[0015] The ground wire post 7 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com