Method for making enameled aluminium flat wire

A production method and enameled aluminum technology, which are used in flat/ribbon cables, cable/conductor manufacturing, electrical components, etc. Defects and hidden dangers of performance defects, avoidance of performance instability, minus the effect of cleaning processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

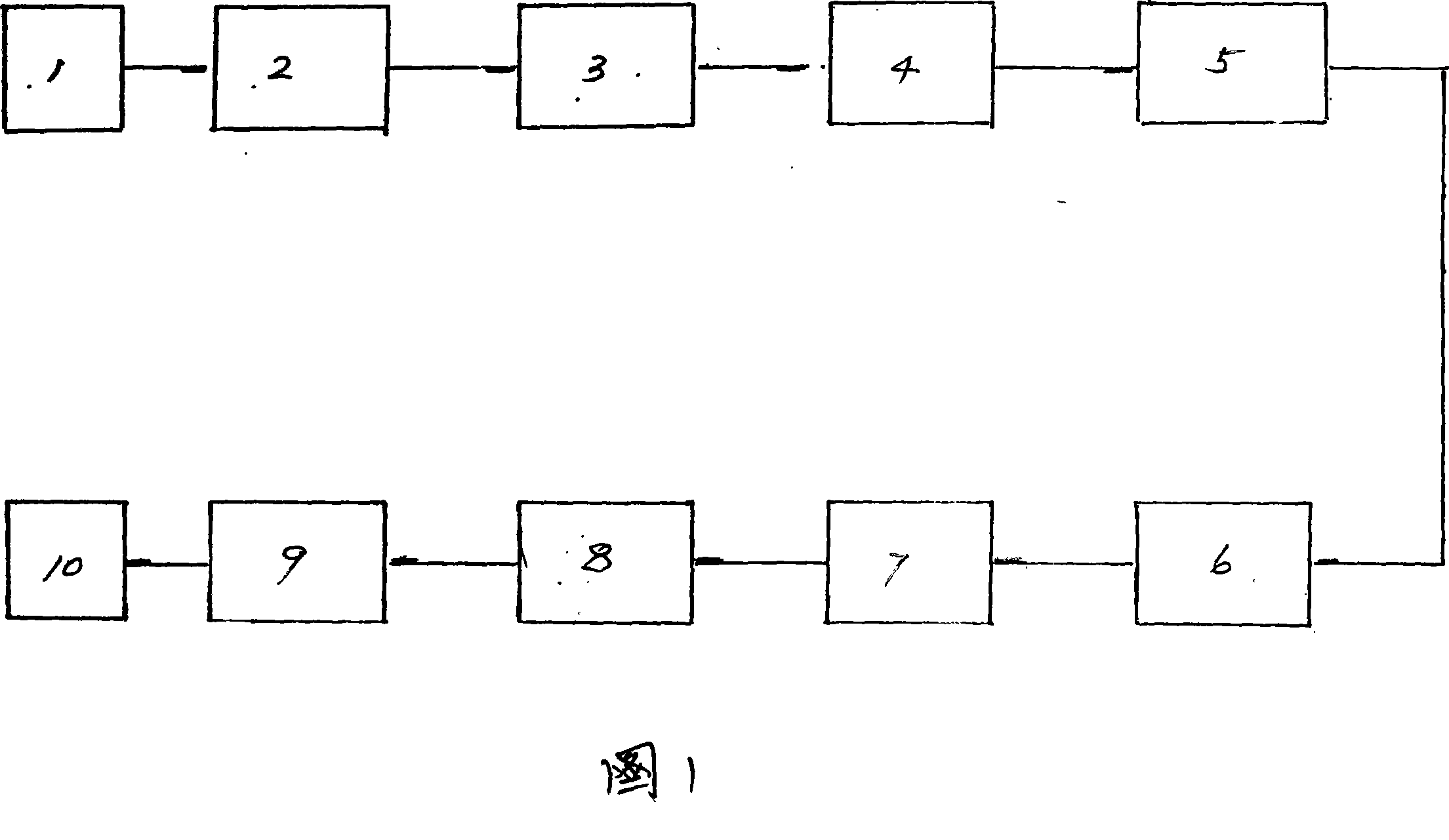

[0032] Pay out the aluminum rod 22 of ¢12.5mm from the pay-off reel 1, and straighten it on the TLJ300 straightening machine 2.

[0033] In the first cleaning tank, use the model DM-215 neutral solution "cooling agent" produced by Jiangyan Demei Chemical Co., Ltd. to clean the aluminum rod 22 for the first time 3; then in the second cleaning tank The aluminum rod 22 is cleaned 3 for the second time with clean water; finally, the aluminum rod 22 is cleaned 3 for the third time with clean water in the third cleaning tank.

[0034] The cleaned aluminum rod 22 enters the extrusion molding equipment for continuous extrusion 4 .

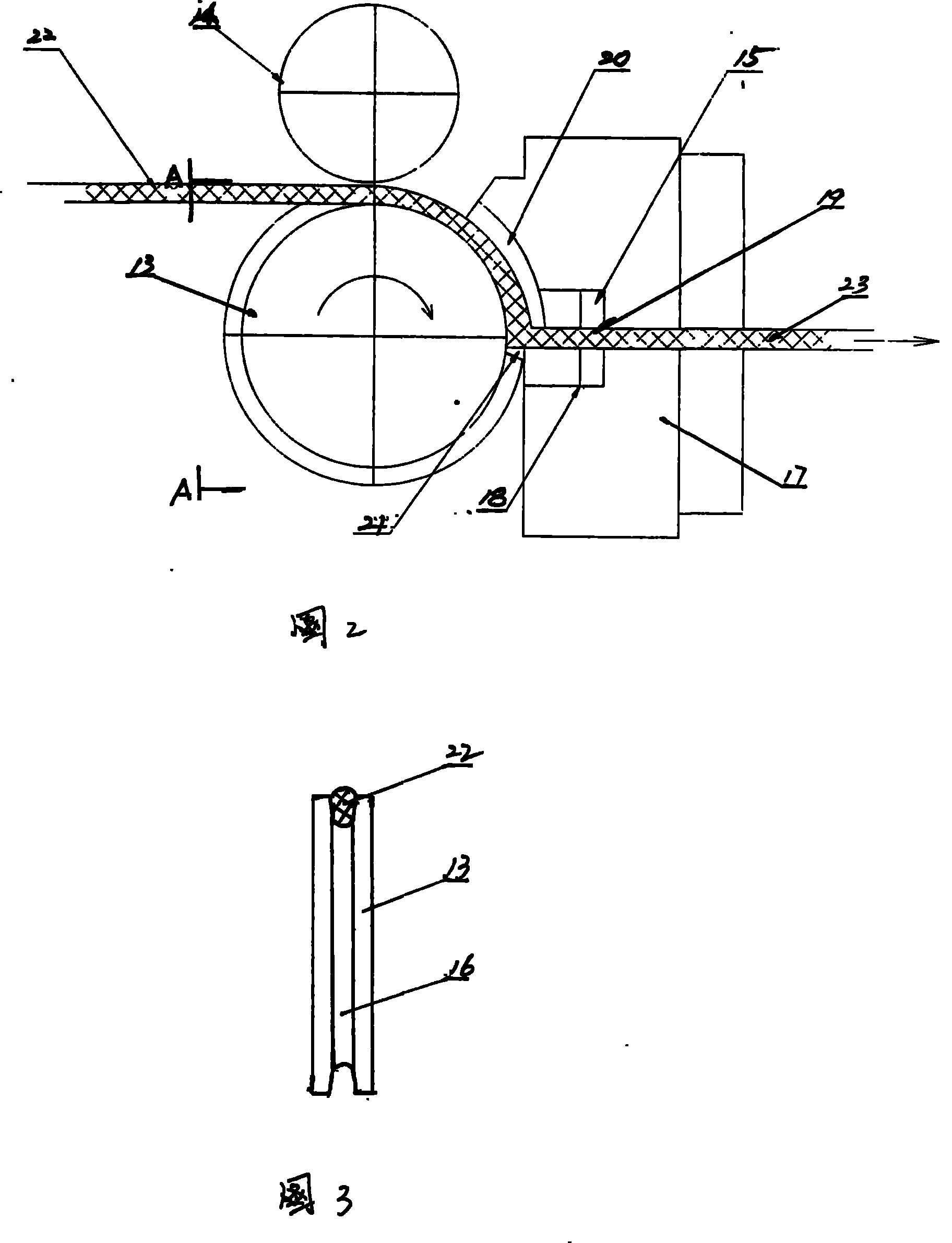

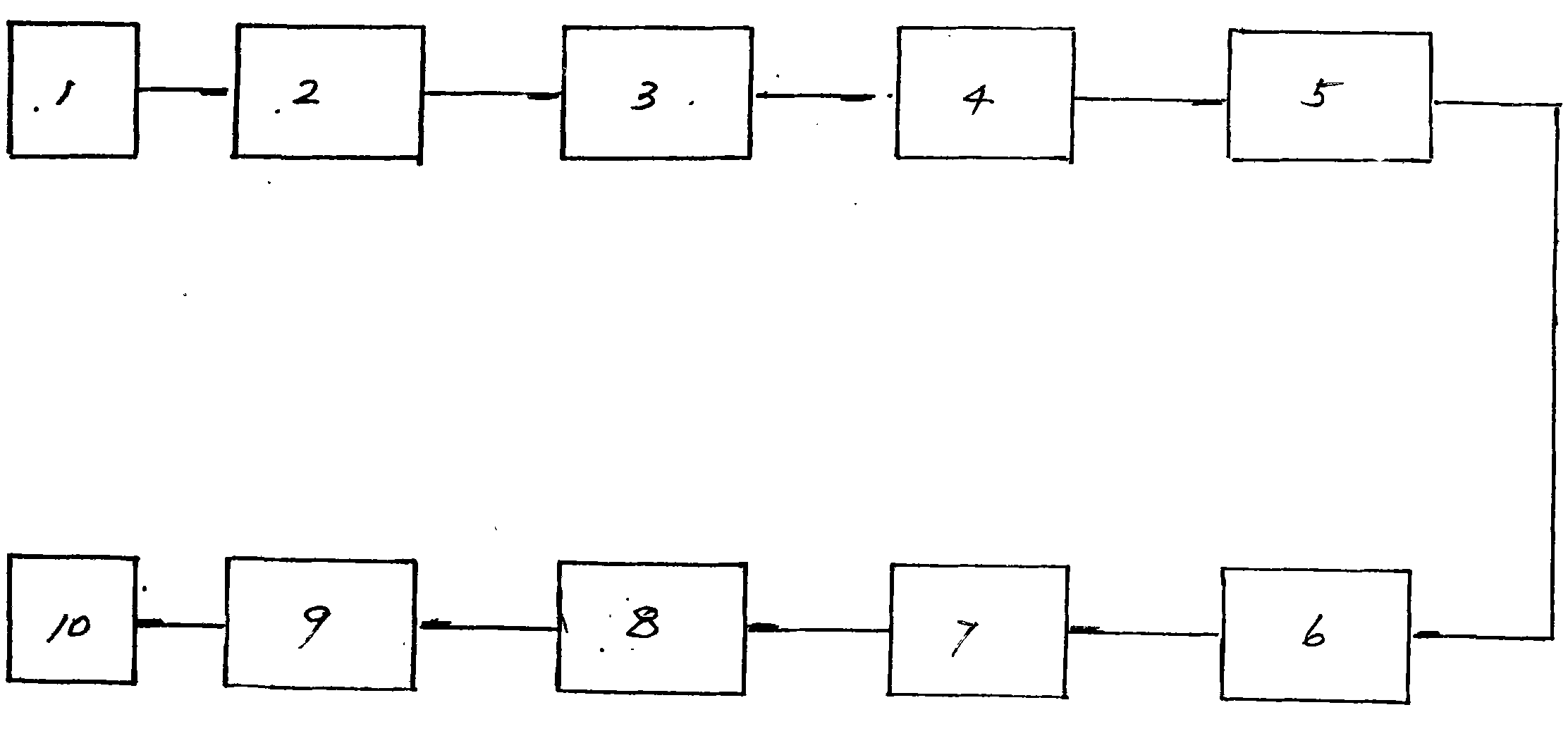

[0035] In the extrusion molding equipment, the aluminum rod 22 enters the position of the annular groove 16 on the roller surface of the extrusion wheel 13, and due to the relative rolling of the extrusion wheel 13 and the compaction wheel 14, the aluminum rod 22 is pressed into the edge of the extrusion wheel 13 In the annular groove 16, and with the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com