Anti-cross valve without choke

An anti-stringing and spool technology, applied to valve details, control valves, valve devices, etc., can solve the problem of interference with the normal flow of air in the spool cavity, poor flue exhaust performance, and poor exhaust in the valve cavity, etc. problem, to achieve the effect of simple installation, low processing cost and smooth exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

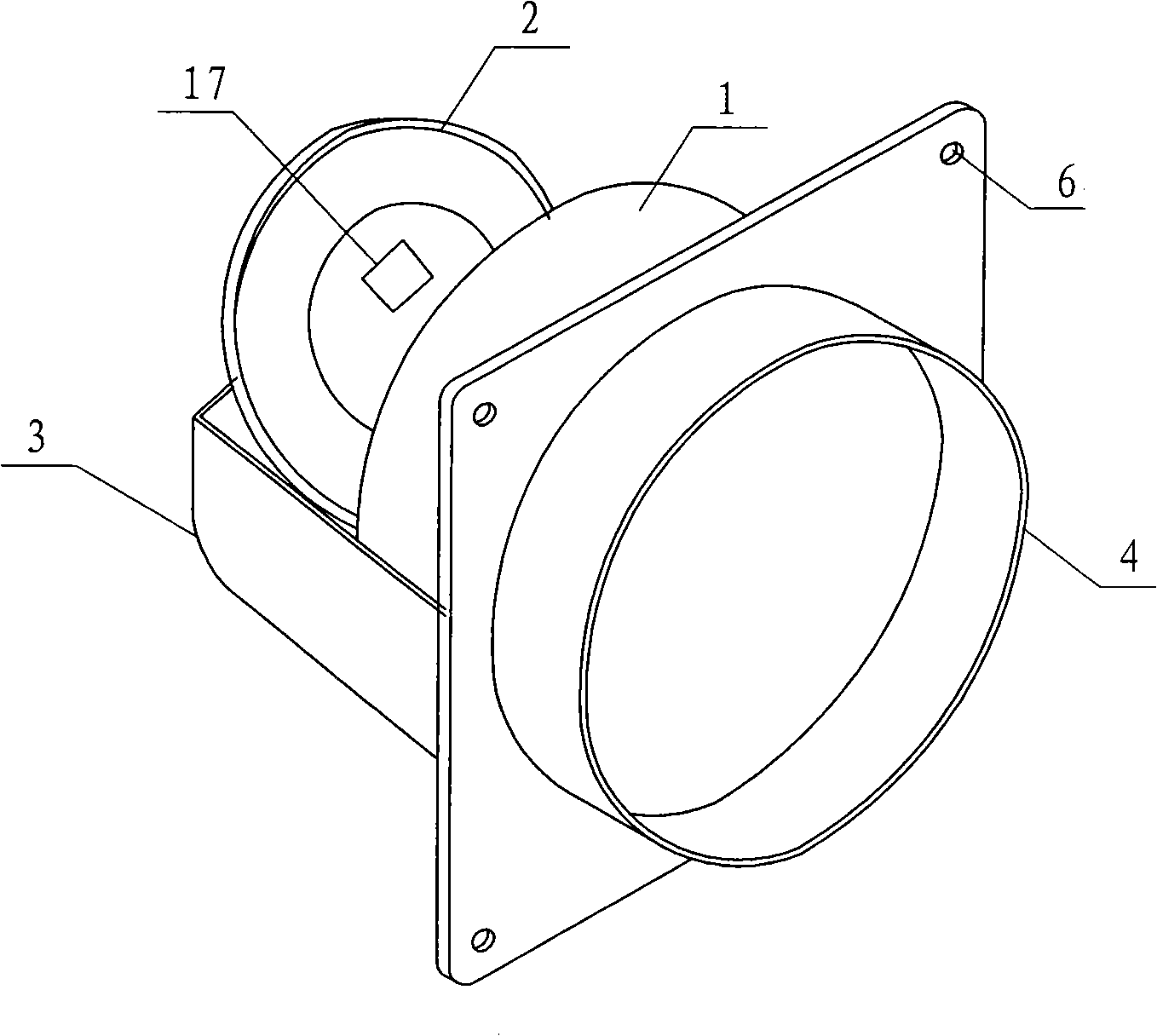

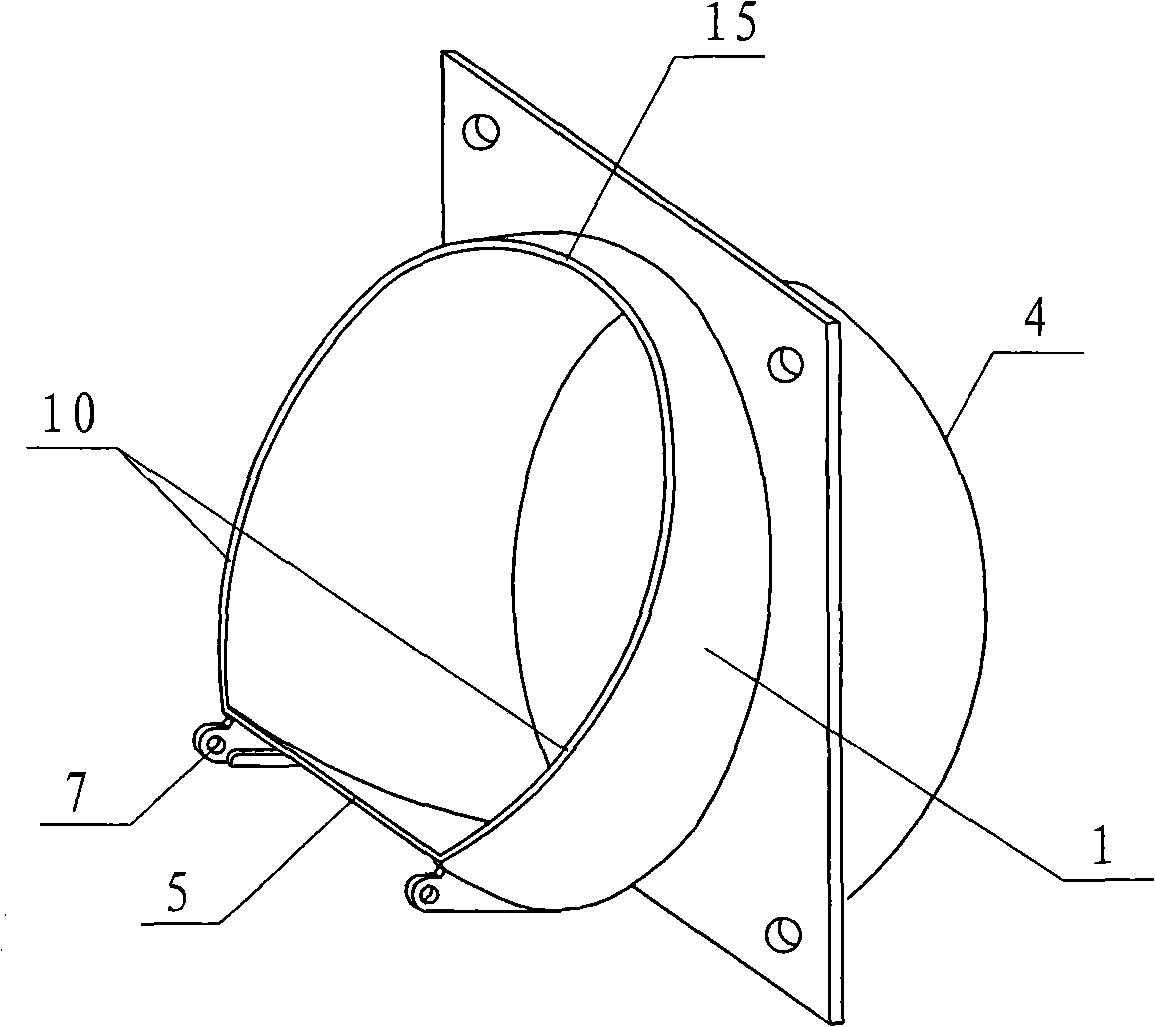

[0027] The specific structure of the non-impeding flow anti-string valve of the present invention is described in detail below in conjunction with the accompanying drawings and specific embodiments:

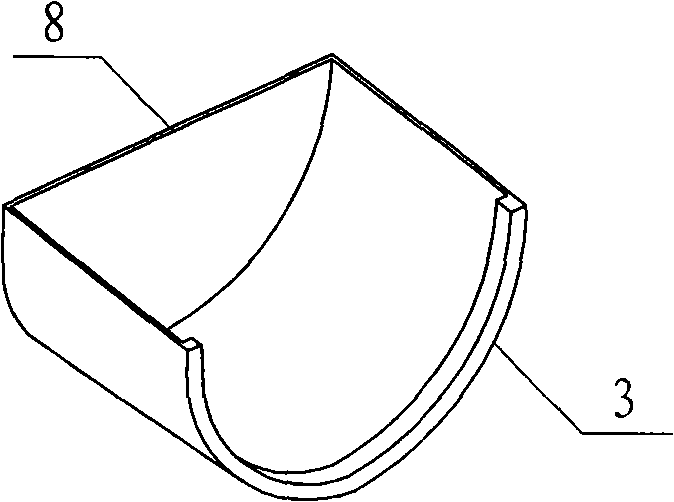

[0028] see Figure 1 to Figure 8 shows a non-restricted flow anti-column valve, which includes: a cylindrical or square cross-section valve core 1, a valve cover 2, a flange port 4, and a semi-cylindrical or square cross-section air guide funnel 3, The angle between the outlet slope 15 of the spool 1 and the horizontal plane is 60-70 degrees, the lower end of the bonnet 2 is hinged to the bottom 5 of the spool 1 through the bonnet shaft 16, and the bonnet 2 return device is The counterweight iron embedded in the inner surface of the bonnet 2, when there is air flow in the cavity of the spool 1, the bonnet 2 opens the bonnet 2 through the bottom shaft 16, due to the role of the embedded counterweight iron 17, the bonnet 2 is in the The center of gravity of the maximum opening pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com