Method for fixing nitrile hydratase strain by sodium alginate-chitosan microcapsules

A technology of nitrile hydratase bacteria and sodium alginate, which is applied in the direction of fixing on/in the organic carrier, can solve the problems of less reaction batches and large loss of enzyme activity, and achieve the effect of good operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

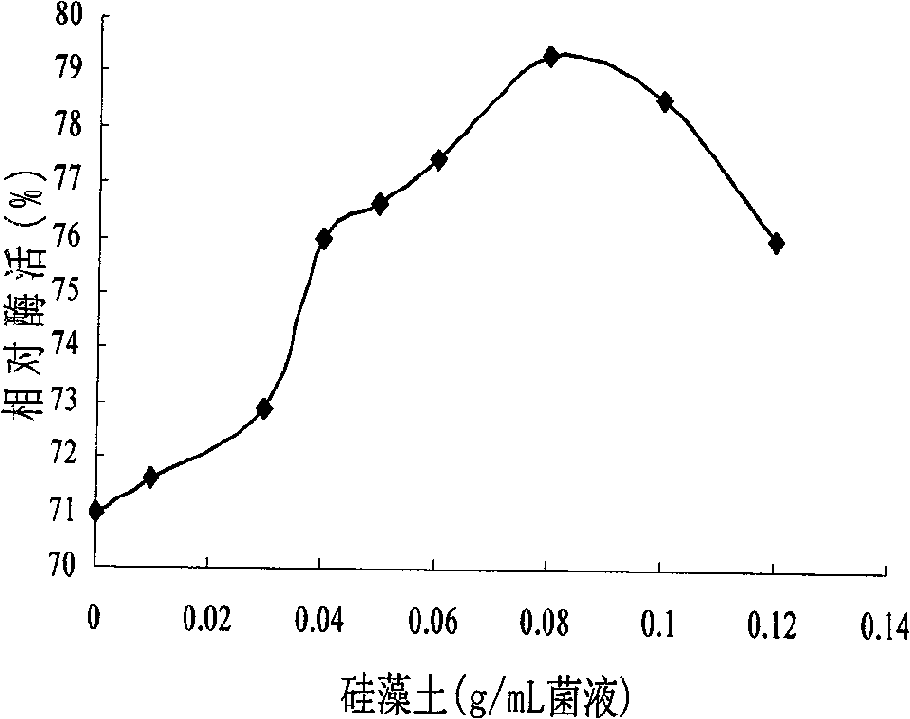

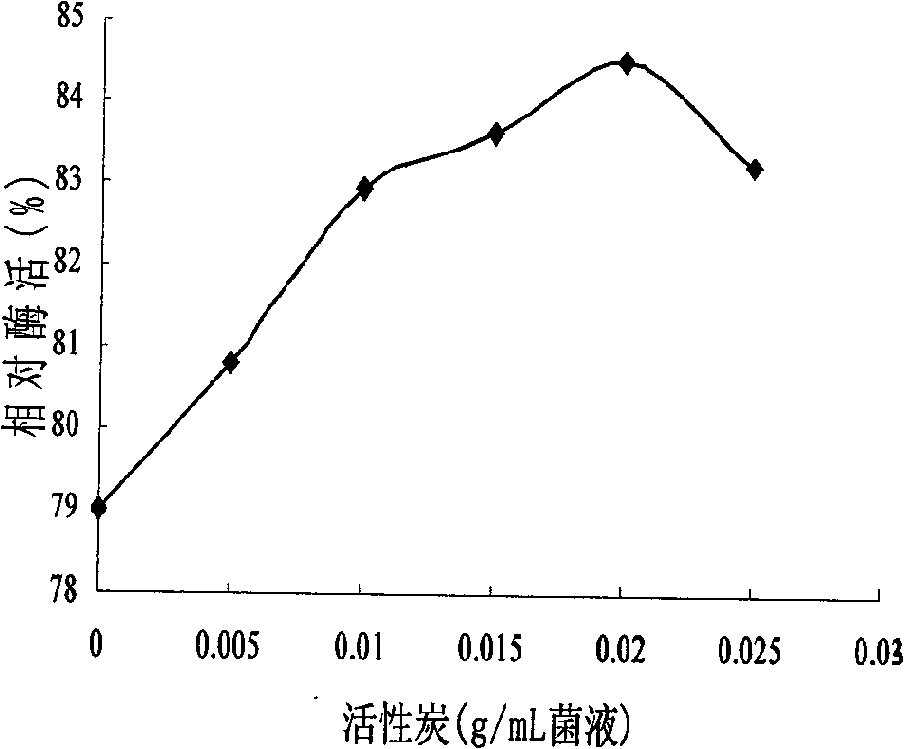

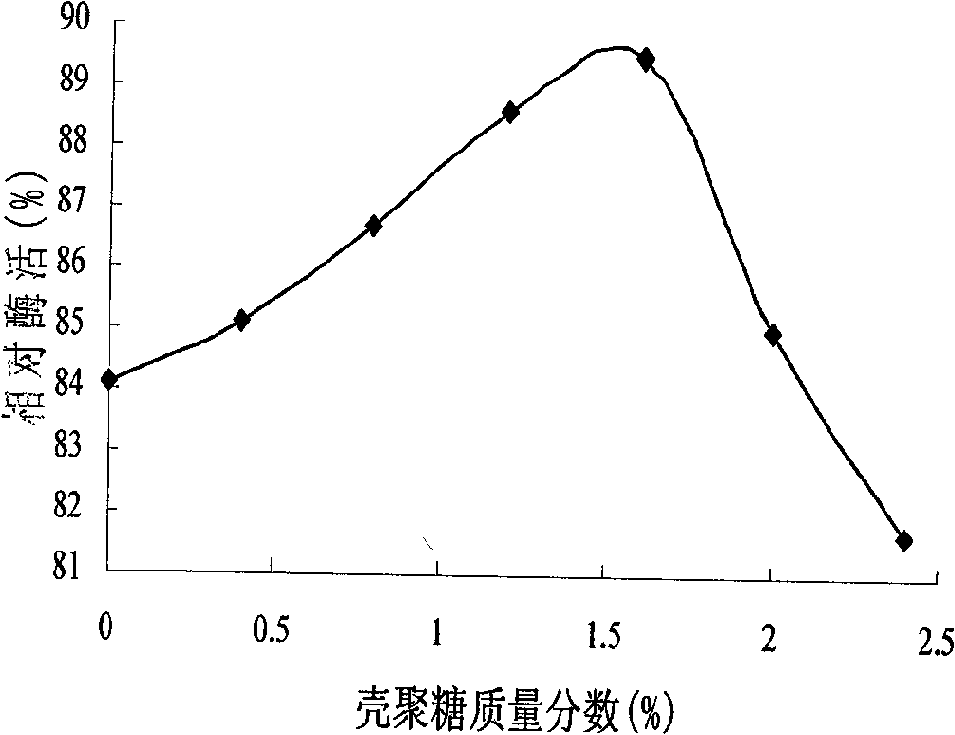

[0008] Specific embodiment one: the method for sodium alginate-chitosan microcapsule immobilization nitrile hydratase bacterial strain in the present embodiment is as follows: one, the sodium alginate that mass concentration is 3.0%-4%, concentration is 50000cfu / ml~80000cfu The nitrile hydratase bacterial suspension, diatomaceous earth and activated carbon of / ml are mixed evenly, then the mixed solution is dripped into the CaCl with a mass concentration of 3.5%-8%. 2 In the solution, after obtaining pellets with a diameter of 2.5-3.5mm, solidify the pellets at a temperature of 4°C for 24 hours, and then filter out the pellets; 2% and chitosan mass fraction of 1.2%-1.8% chitosan acetic acid solution for 20min-40min, then filter out the pellets, and then wash 3 times with distilled water to obtain sodium alginate-chitosan Microcapsules; wherein the volume ratio of the nitrile hydratase bacterial suspension with a concentration of 50000cfu / ml to 80000cfu / ml and the sodium algina...

specific Embodiment approach 2

[0012] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the concentration in step one is the volume of the nitrile hydratase bacterial suspension of 50000cfu / ml~80000cfu / ml and the mass concentration of 3.0%-4% sodium alginate The ratio is 1:15-25. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the concentration in step one is the volume of the nitrile hydratase bacterial suspension with a concentration of 50000cfu / ml~80000cfu / ml and the sodium alginate with a mass concentration of 3.0%-4%. The ratio is 1:20. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com