Slump retaining polyocarboxy acid superplasticiser

A technology of superplasticizer and type polycarboxylate, which is applied in the field of concrete admixture, can solve the problem of low water-reducing rate of polycarboxylate superplasticizer and achieve high slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

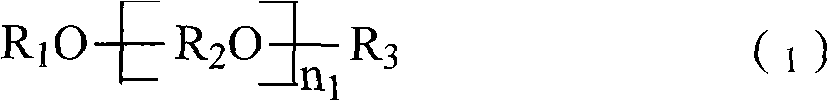

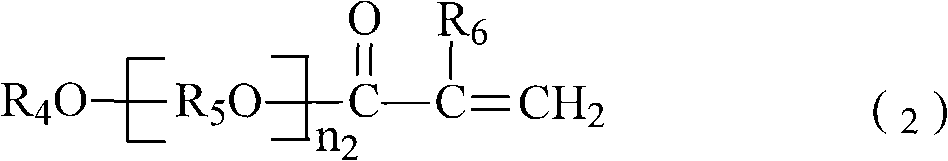

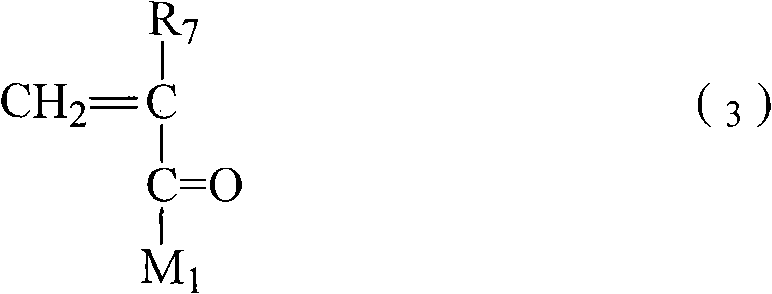

Method used

Image

Examples

Embodiment 1

[0038] Add 45.0g of A-1, 7.5g of itaconic acid, and 100.0g of deionized water into a 500ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, stir and heat up to 80°C, and dropwise add 22.5g of 10% Aqueous solution of ammonium persulfate and monomer aqueous solution composed of 90.0g of B-1, 7.5g of methacrylic acid, 0.80g of 2-mercaptopropionic acid and 45.0g of water, the dropping time is controlled at 120 minutes and 90 minutes respectively, and the reaction The temperature is controlled at 78-82°C. After the dropwise addition, keep the temperature at 78-82°C for about 60 minutes to complete the polymerization reaction. After the heat preservation is finished, cool down to below 50° C. and add 27.0 g of 30% NaOH to obtain the polycarboxylate superplasticizer PC-1 of the present invention, which has a solid content of 45.4% and a weight average molecular weight of 22,500.

Embodiment 2

[0040] Add 82.5g of A-3, 9.0g of itaconic acid, and 120.0g of deionized water into a 500ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and stir to raise the temperature to 90°C; at the same time, dropwise add 22.5g of 10% Sodium persulfate aqueous solution and monomer aqueous solution composed of 48.0g of B-4, 10.5g of acrylic acid, 0.60g of 3-mercaptopropionic acid and 65.0g of water, the dropping time is controlled at 120 minutes and 90 minutes respectively, and the reaction temperature is controlled At 88-92°C. After the dropwise addition, keep the temperature at 88-92°C for about 60 minutes to complete the polymerization reaction. After the heat preservation is finished, cool down to below 50°C and add 37.9g of 30% NaOH to obtain the polycarboxylate superplasticizer PC-2 of the present invention, which has a solid content of 40.0% and a weight-average molecular weight of 25,000.

Embodiment 3

[0042]Add 67.5g of A-4, 3.0g of itaconic acid, and 120.0g of deionized water into a 500ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and stir to raise the temperature to 70°C; at the same time, dropwise add 22.5g of 10% Potassium persulfate aqueous solution and monomer aqueous solution composed of 67.5g of B-2, 12.0g of methacrylic acid, 1.20g of mercaptoacetic acid and 70.0g of water, the dropping time was controlled at 120 minutes and 90 minutes respectively, and the reaction temperature was controlled at 68 ~72°C. After the dropwise addition, keep the temperature at 68-72°C for about 60 minutes to complete the polymerization reaction. After the heat preservation finishes, cool down to below 50°C and add 24.8g of 30% NaOH to obtain the polycarboxylate superplasticizer PC-3 of the present invention, with a solid content of 40.4% and a weight-average molecular weight of 16,500.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com