Air drop automatic energy-absorbing vibration absorption flat-bed of heavy device

A technology for heavy equipment and cargo platforms, which is applied in the field of air-dropped self-absorbing energy-absorbing and vibration-reducing cargo platforms for heavy equipment. The effect of small parachute area and reduced time in the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

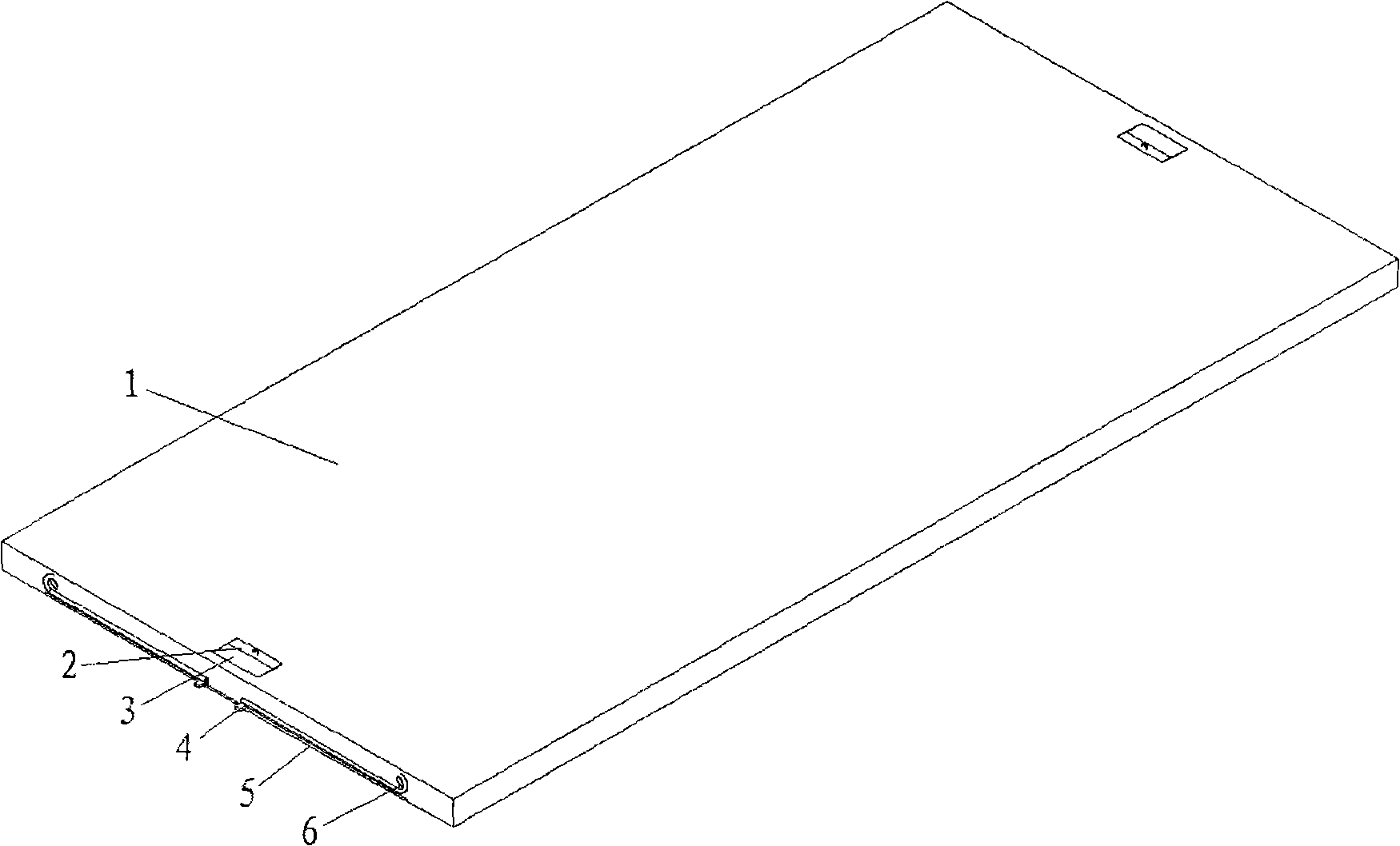

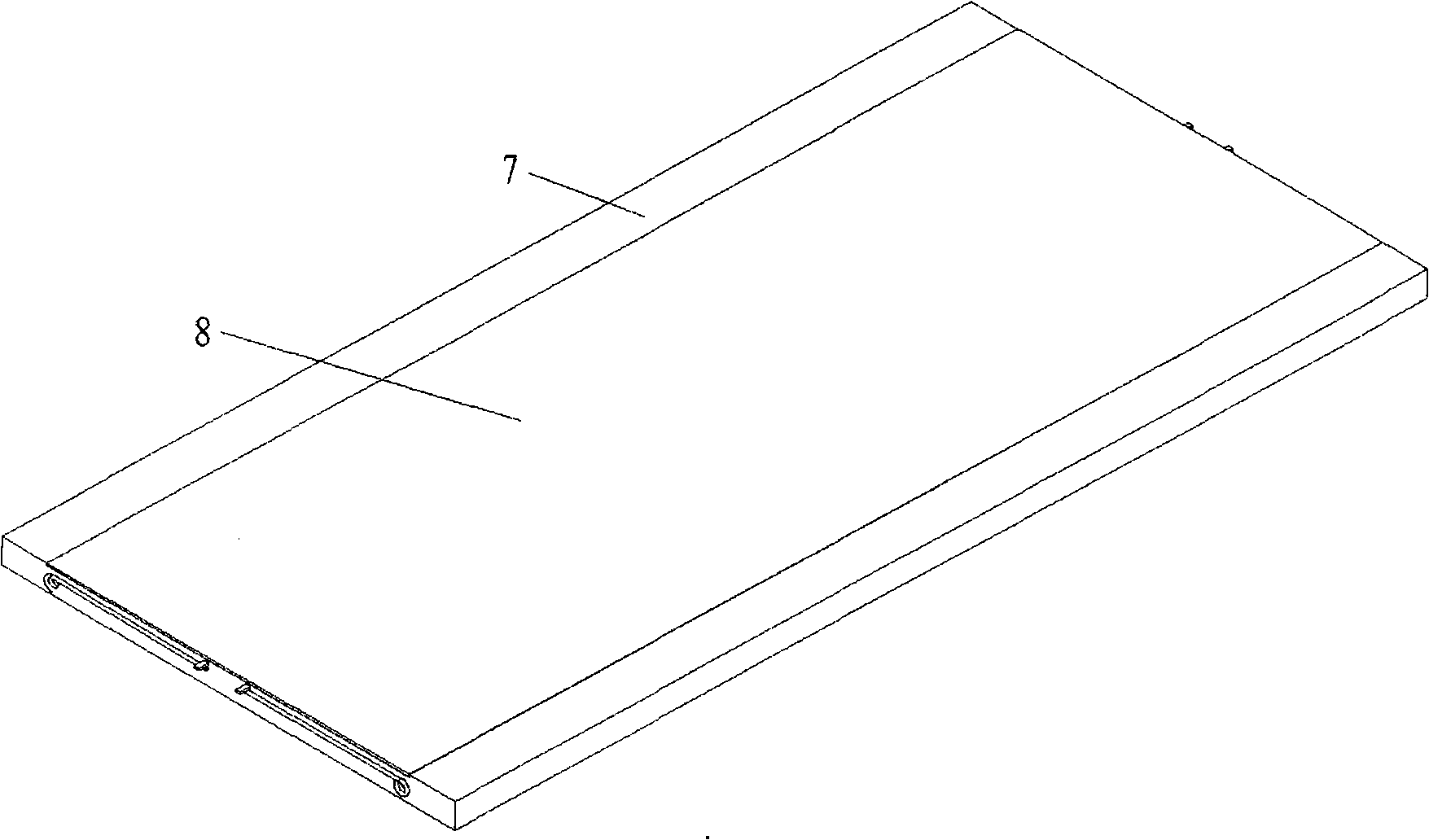

[0015] Such as figure 1 As shown, when the airdrop is in the installed and ready-to-drop state, the release lock and unlock slider 2 is in the cargo platform, the release lock and unlock slider is against the release slider 3, and the release slider compresses the reverse push spring 12, and the dead bolt 4 Arrive at the edge of the delivery platform, block the torsion spring rod 5, and the buffer mechanism of the delivery platform is in a locked state, as Figure 5 , Figure 7 shown. When the airdrop is off the aircraft, the main parachute lifts the sling, and the unlocking pull rope (one end connected to the connecting ring of the unlocking slider) connected to the main parachute sling is straightened with the main parachute, and the release lock is pulled up to unlock the slider 2, lock Tongue 4 returns to the inside of the cargo platform under the action of the anti-thrust spring force, such as Figure 8 As shown, the torsion spring bar 5 is released, and the torsion sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com