Lathe-milling consubstantial machine tool

A machine tool, turning and milling technology, applied in metal processing mechanical parts, metal processing equipment, manufacturing tools, etc., can solve the problems of large structure size, large work space, inconvenient movement, etc., and achieve easy lightweight, wide applicability, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

[0036] Embodiment 2 differs from Embodiment 1 in that this embodiment describes another specific spindle device structure. refer to Figure 7 , said main shaft device 4 is a kind of split main shaft. The main shaft device 4 includes a box body 4-1, a main shaft motor 4-2, a main shaft motor bracket 4-3, a pulley 4-4, a belt 4-5, a pulley 4-6 and a main shaft 5. The main shaft motor support 4-3 is arranged on the box body 4-1, and the main shaft motor 4-2 is installed on the main shaft motor support 4-3. The main shaft 5 traverses the casing 4-1, and the rotation centerline of the output shaft of the main shaft motor 4-2 is arranged parallel to the rotation centerline of the main shaft 5. The belt pulley 4-6 that is arranged on the main shaft 5 is connected with the belt pulley 4-4 that is arranged on the output shaft of the main shaft motor 4-2 through the belt 4-5, and the rotary motion of the main shaft 5 around its own rotation center line is passed by the rotation of the...

Embodiment approach 3

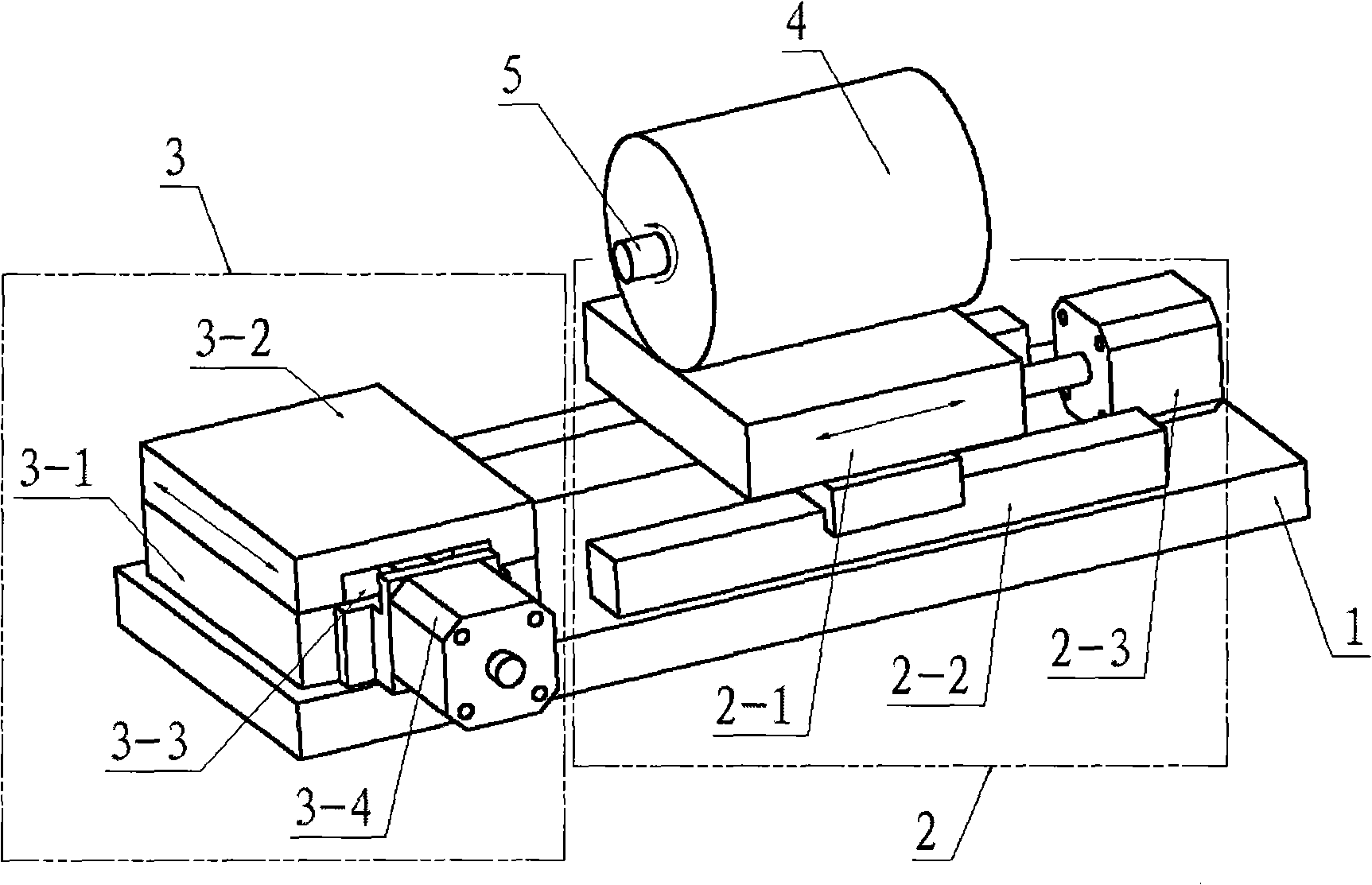

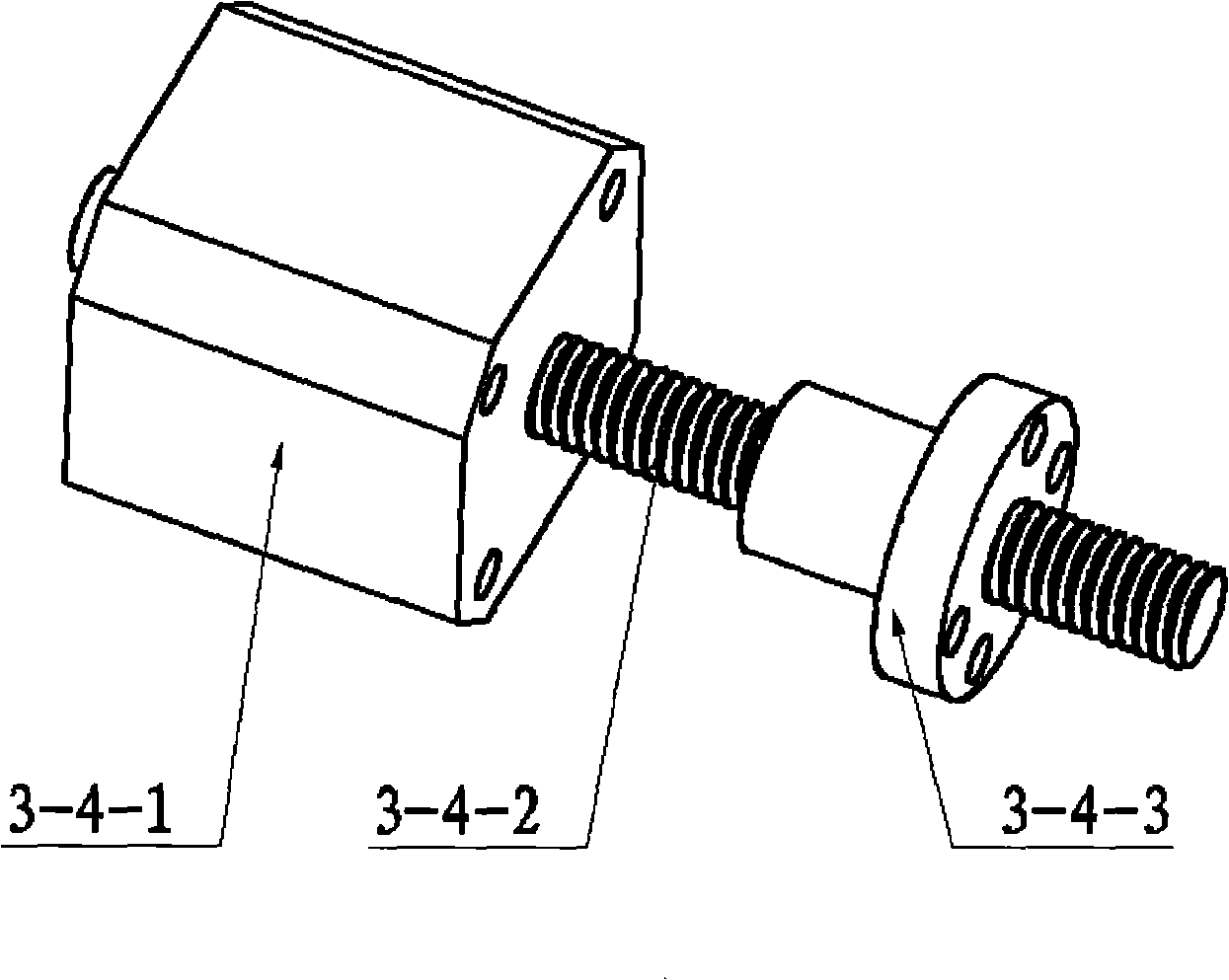

[0037] The difference between embodiment 3 and embodiment 1 or 2 is that this embodiment describes another improved structure of the work slide and the rotary table. like Figure 8 , The first working slide table 2 includes a slider 2-1, a rolling guide rail 2-2, a motor 2-3, and a hand wheel 2-4. The handwheel 2-4 is arranged on the motor 2-3 shaft, and the rotation of the handwheel 2-4 drives the linear reciprocating motion of the slider 2-1. like Figure 9 , The second working slide table 3 includes a slide table base 3-1, a slide block 3-2, a rolling guide rail 3-3, an integrated motor-screw nut pair 3-4 and a hand wheel 3-5. The handwheel 3-5 is arranged on the motor 3-4-1 shaft, and the rotation of the handwheel 3-5 drives the linear reciprocating motion of the slider 3-2. like Figure 10 , the third working slide 6 includes a slide base 6-1, a slider 6-2, a rolling guide 6-3, an integrated motor-screw nut pair 6-4 and a hand wheel 6-5. The hand wheel 6-5 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com