Circulating fluid bed flue gas desulfurization technique and device

A circulating fluidized bed and desulfurization process technology, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc. Low maintenance cost, simple system structure, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

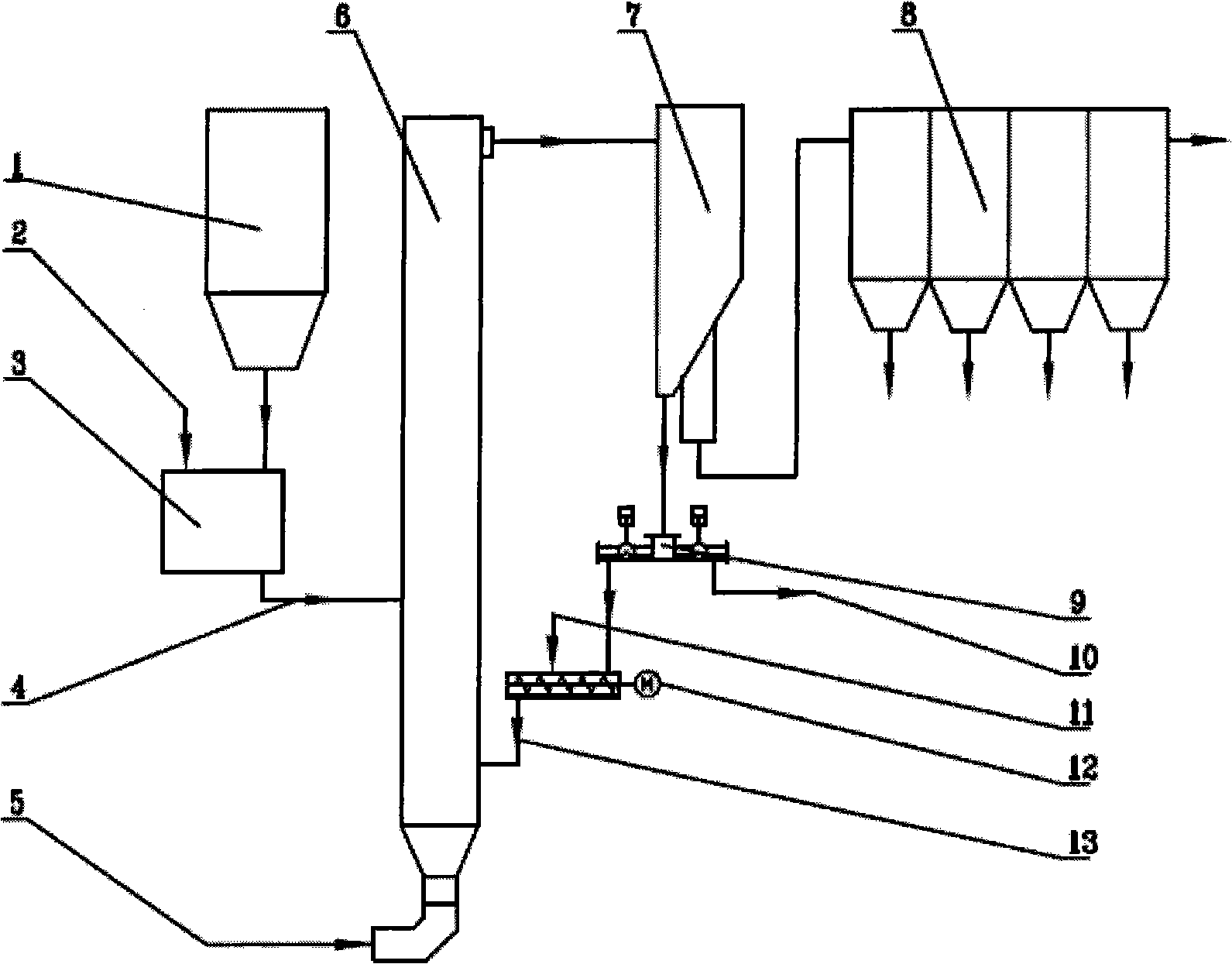

Embodiment 1

[0027] A power station boiler emits 120,000 Nm of flue gas 3 / Hour, flue gas temperature 145℃, sulfur content 3770mg / Nm 3 , The desulfurization device adopts a single tower structure, equipped with a single cyclone separator, the diameter of the desulfurization tower is 3.5m, the diameter of the cyclone separator is 4m, and the cyclone separator is designed with two ash outlets, and the separation efficiency is 92%. The humidification activator adopts mechanical stirring, spraying water for humidification, and the humidification water consumption is 4.2T / h. The secondary dust collector adopts a four-electric field electrostatic precipitator. The desulfurized ash from the first two electric fields is returned to the desulfurization tower, and the desulfurized ash from the latter two electric fields is directly sent to the ash storage. Slaked lime powder is used as the desulfurizing agent, the fineness is 150-300, and the molar ratio of Ca / S is 1.3.

[0028] The hot flue gas enters ...

Embodiment 2

[0030] A power station boiler emits 210,000 Nm of flue gas 3 / Hour, flue gas temperature 145℃, sulfur content 3500mg / Nm 3 , The desulfurization device adopts a double tower structure with double cyclone separators. The diameter of the desulfurization tower is 3.2m, the diameter of the cyclone separator is 3.6m, and the cyclone separator is designed with two ash discharge ports, and the separation efficiency is 95%. The humidification activator adopts mechanical stirring, steam humidification, and humidification water consumption is 7.2T / h. The secondary dust collector adopts a four-field electrostatic dust collector, and its desulfurized ash is directly sent to the ash warehouse. Slaked lime powder is used as the desulfurizing agent, the fineness is 150-300, and the molar ratio of Ca / S is 1.3.

[0031] During normal operation, the circulating ash separated by the cyclone (6) is about 80T / h, all of which are broken by the circulating ash humidification activator (12), sprayed for h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com