Method for controlling dehumidification rate and heat pump drier for implementing dehumidification rate control

A rate control, heat pump drying technology, applied in dryers, drying solid materials, drying gas layout, etc., can solve problems such as inability to achieve dehumidification rate, energy waste of equipment potential, and inability to achieve maximum dehumidification rate control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

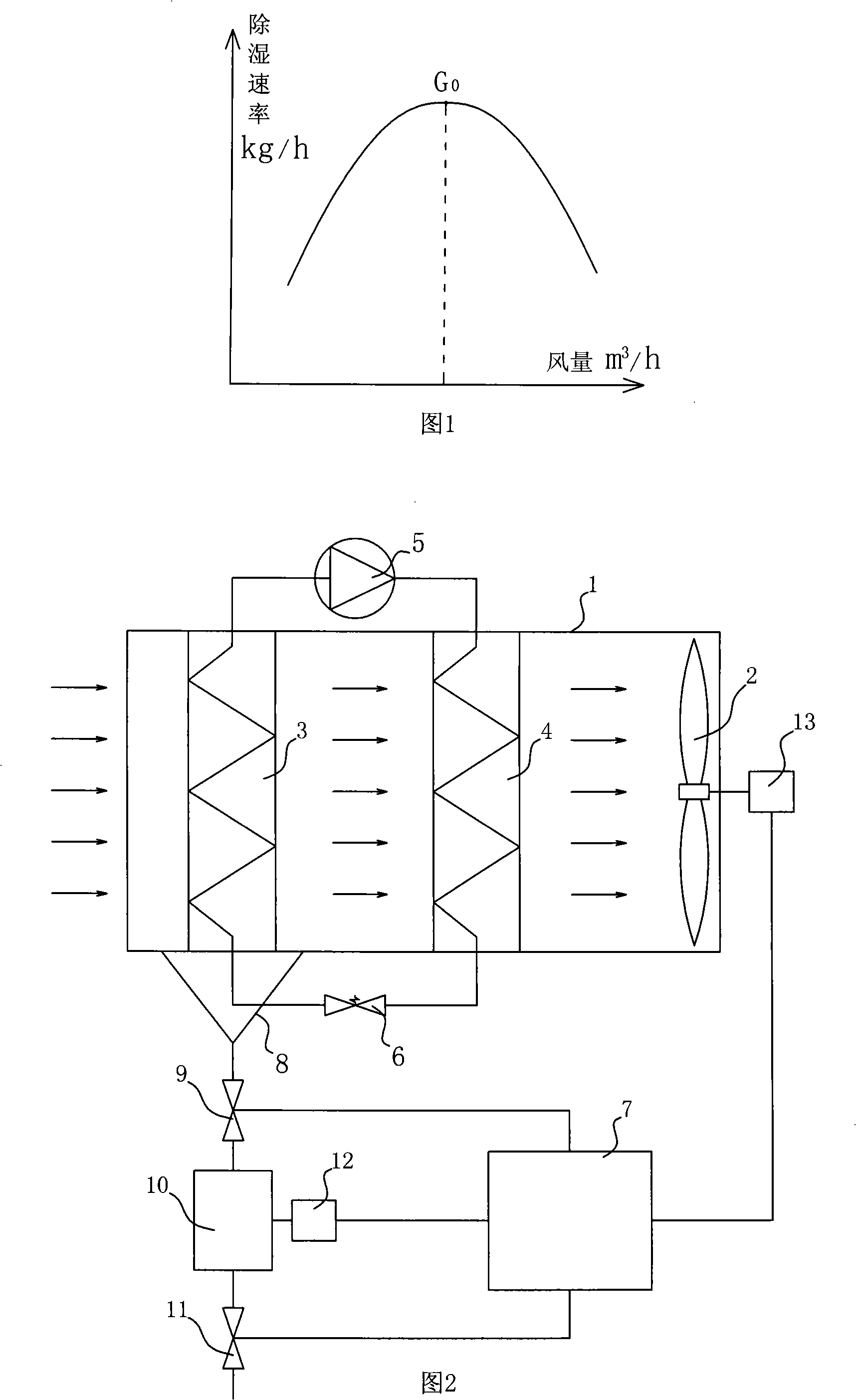

[0015] As shown in FIG. 1 , the heat pump dryer for realizing dehumidification rate control according to the present invention includes an airflow channel 1 , and a cooling device 3 and a heating device 4 are arranged in the airflow channel 1 . The cooling device 3 and the heating device 4 can be an evaporator and a condenser respectively, and a compressor 5 and an expansion valve 6 are connected between the evaporator and the condenser, and the evaporator, the condenser, the compressor 5, and the expansion valve 6 form a causative Cold medium circulation. The air flow channel 1 is provided with a fan 2 for making the air flow through the cooling device 3 and the heating device 4 in sequence. There is also a computer 7 and a water collector 8 that collects the condensed water of the cooling device 3. The water collector 8 can be a funnel located below the evaporator. When water condenses on the evaporator, the water will flow to the water collector. 8 in. The water collector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com