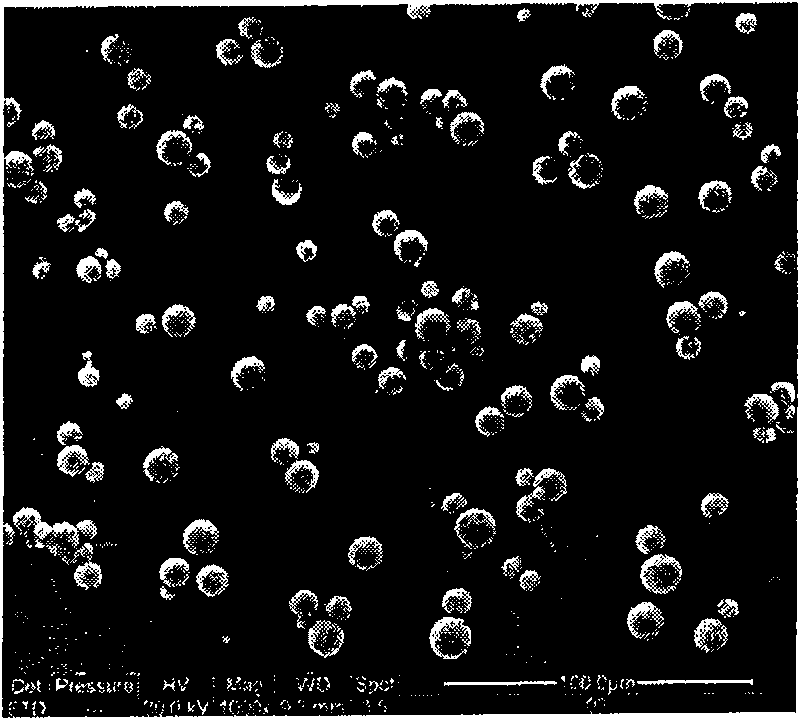

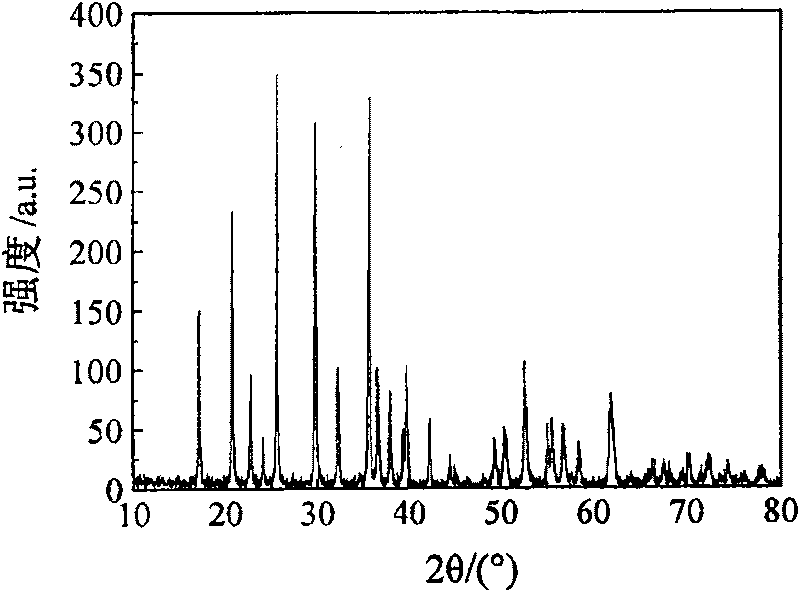

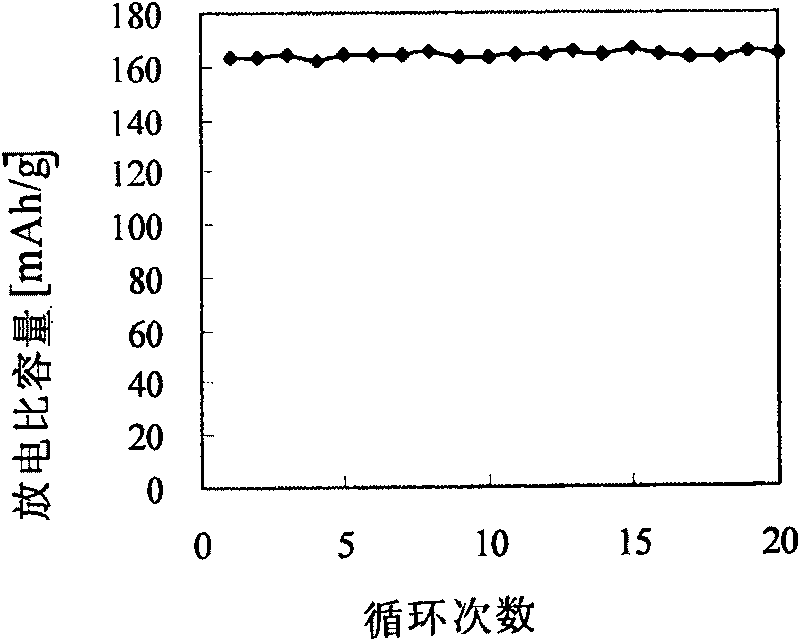

Preparation of micron-size spherical LiFePO4 material

A micron-scale, spherical technology, applied in the field of lithium battery material science and electrochemistry, can solve problems such as small tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Prepare a diammonium hydrogen phosphate solution with a concentration of 1.0 mol / L and a mixed solution of 1.0 mol / L ferrous sulfate and ammonium citrate with a molar ratio of 1:1 with deaerated deionized water; The mixed solution of ferrous iron and ammonium citrate is used as the base liquid, the temperature is controlled at 30°C, and the diammonium hydrogen phosphate solution is added dropwise with a constant flow pump while stirring. When the reaction liquid turns milky, stop the dropwise addition, react for 10 minutes, and centrifuge to separate the product , and washed with double distilled water until the clear liquid is colorless, that is, to obtain (NH 4 )FePO 4 . Will (NH 4 )FePO 4 Added to a concentration of 1wt% methyl cellulose aqueous solution, and then added with (NH 4 )FePO 4 Equimolar LiOH, ultrasonically dispersed for 5 minutes to form (NH 4 )FePO 4 Dispersion at 10% by weight. Mix Span-80 and liquid paraffin in a mass ratio of 1:100, put it in...

Embodiment 2

[0023] Prepare the diammonium hydrogen phosphate solution with a concentration of 1.75 mol / L and the mixed solution of 1.75 mol / L ferrous sulfate and ammonium citrate with a molar ratio of 1:1 with deaerated deionized water; The mixed solution of ferrous iron and ammonium citrate is used as the base solution, and the temperature is controlled at 55°C. While stirring, the diammonium hydrogen phosphate solution is added dropwise with a constant flow pump. When the reaction solution turns milky, stop the dropwise addition, react for 30 minutes, and centrifuge to separate the product , and washed with double distilled water until the clear liquid is colorless, that is, to obtain (NH 4 )FePO 4 . Will (NH 4 ) FePO 4 Added to a concentration of 3wt% methyl cellulose aqueous solution, and then added with (NH 4 ) FePO 4 Equimolar LiOH, ultrasonically dispersed for 10 minutes to form (NH 4 ) FePO 4A dispersion with a content of 20% by weight. Mix Span-80 and liquid paraffin in a...

Embodiment 3

[0025] Prepare the diammonium hydrogen phosphate solution with a concentration of 2.5mol / L and the mixed solution of ferrous sulfate and ammonium citrate with a molar ratio of 1:1 with a concentration of 2.5mol / L and ammonium citrate with deaerated deionized water; The mixed solution of ferrous iron and ammonium citrate is used as the base liquid, and the temperature is controlled at 80°C. While stirring, the diammonium hydrogen phosphate solution is added dropwise with a constant flow pump. When the reaction solution becomes milky, stop the dropwise addition, react for 50 minutes, and centrifuge to separate the product , and washed with double distilled water until the clear liquid is colorless, that is, to obtain (NH 4 ) FePO 4 . Will (NH 4 ) FePO 4 Added to a concentration of 5wt% methyl cellulose aqueous solution, and then added with (NH 4 )FePO 4 Equimolar LiOH, ultrasonically dispersed for 15 minutes to form (NH 4 )FePO 4 A dispersion with a content of 30% by weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com