Precision grain drill with seedling-cultivation plate of rice

A technology of precision seeding and seeding machine, applied in the direction of single-seed seeding machine, seeding machine parts, etc., can solve the problems of low seeding precision, poor adjustability of seeding amount, high price, and achieve good seeding performance, reliable work and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

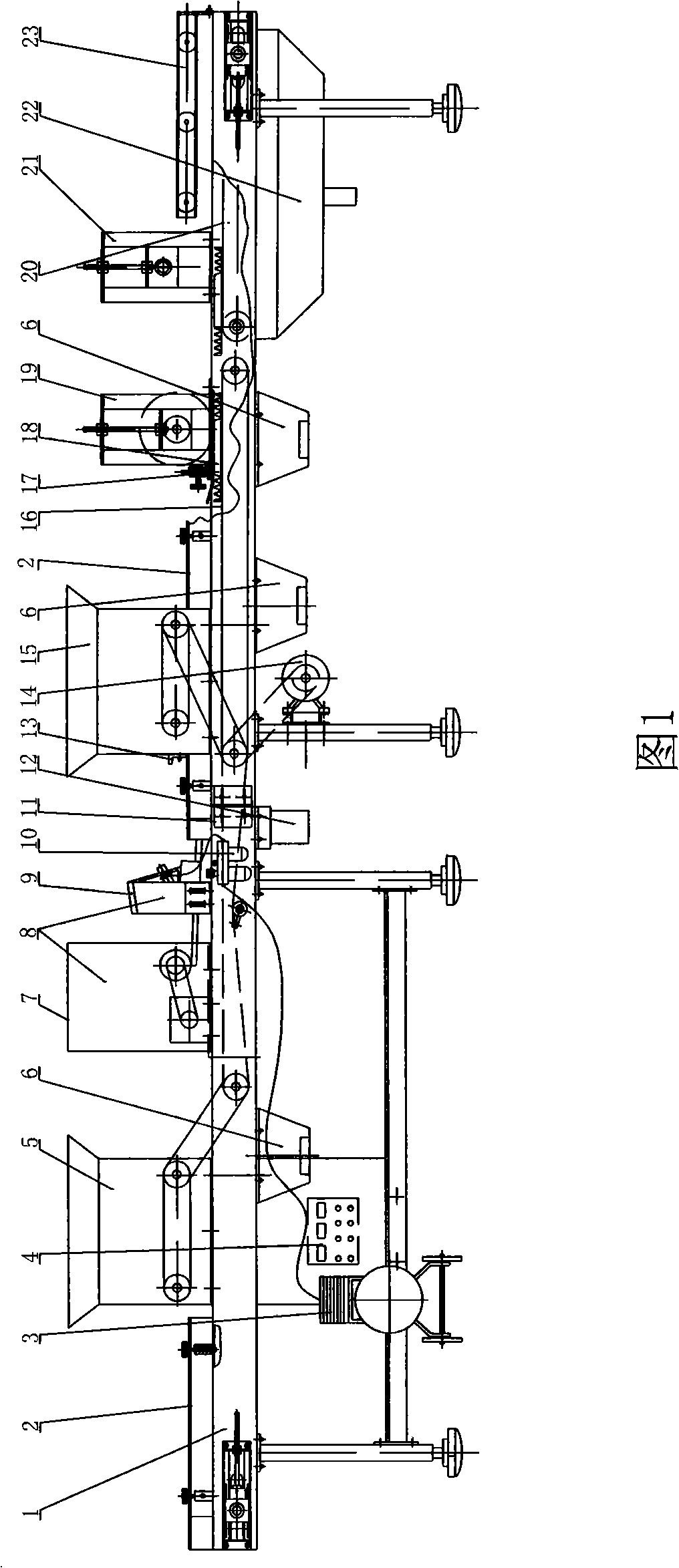

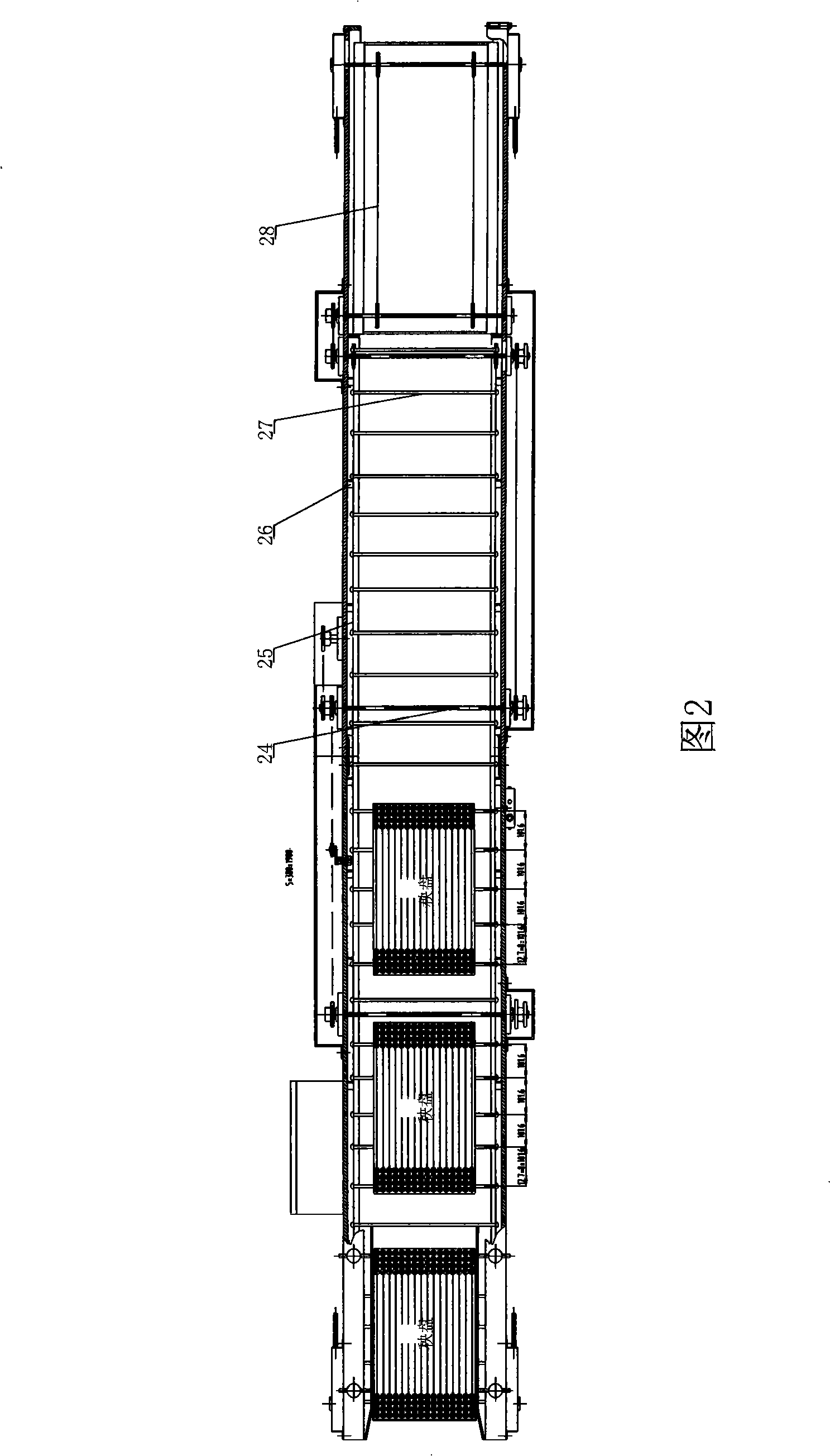

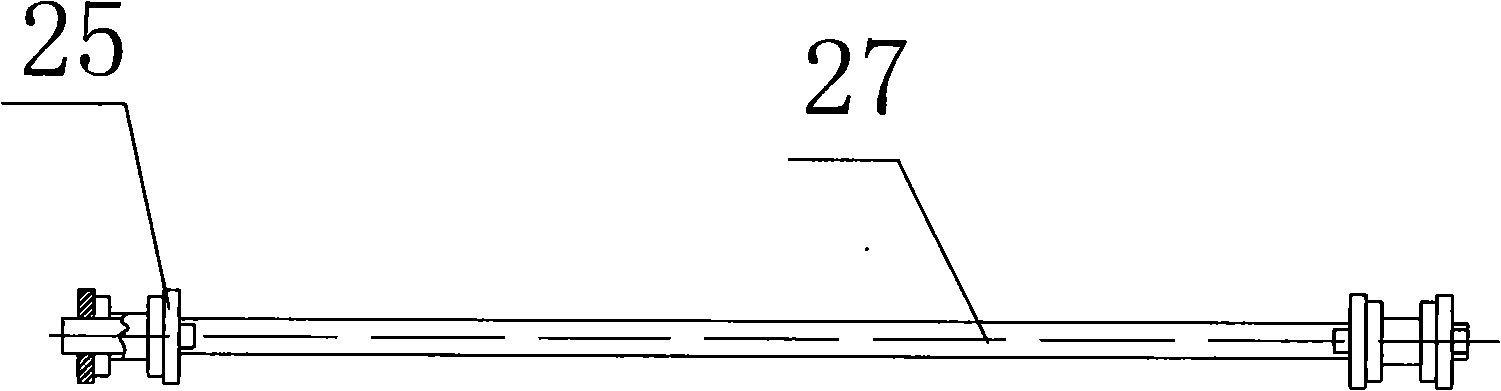

[0021] As shown in Figure 1, a rice seedling tray seedling raising precision seeding machine, it includes the frame 1 that is formed by the front and rear two sections that are connected into one through the connecting plate 11, and the frame 1 that is used to limit the seedling tray in the front section of the frame 1 is arranged successively. Seedling tray limiting mechanism 2, bottom soil laying device 5, precision seeding device 8, the chain-type support bar conveying mechanism 16 for conveying seedling tray 18 inside the frame 1 and the precision seeding mechanism located at the lower side of the frame 1 The air compressor 3 connected to the device 8 and the main motor 14 connected to each mechanism.

[0022] The planter also includes an electric control box 4 that is located at the front section of the frame 1 to control the actions of various mechanisms and a gas pressure regulating valve 10 that is connected between the precision seeding device 8 and the air compressor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com