Automated tuning of large-scale multivariable model predictive controllers for spatially-distributed processes

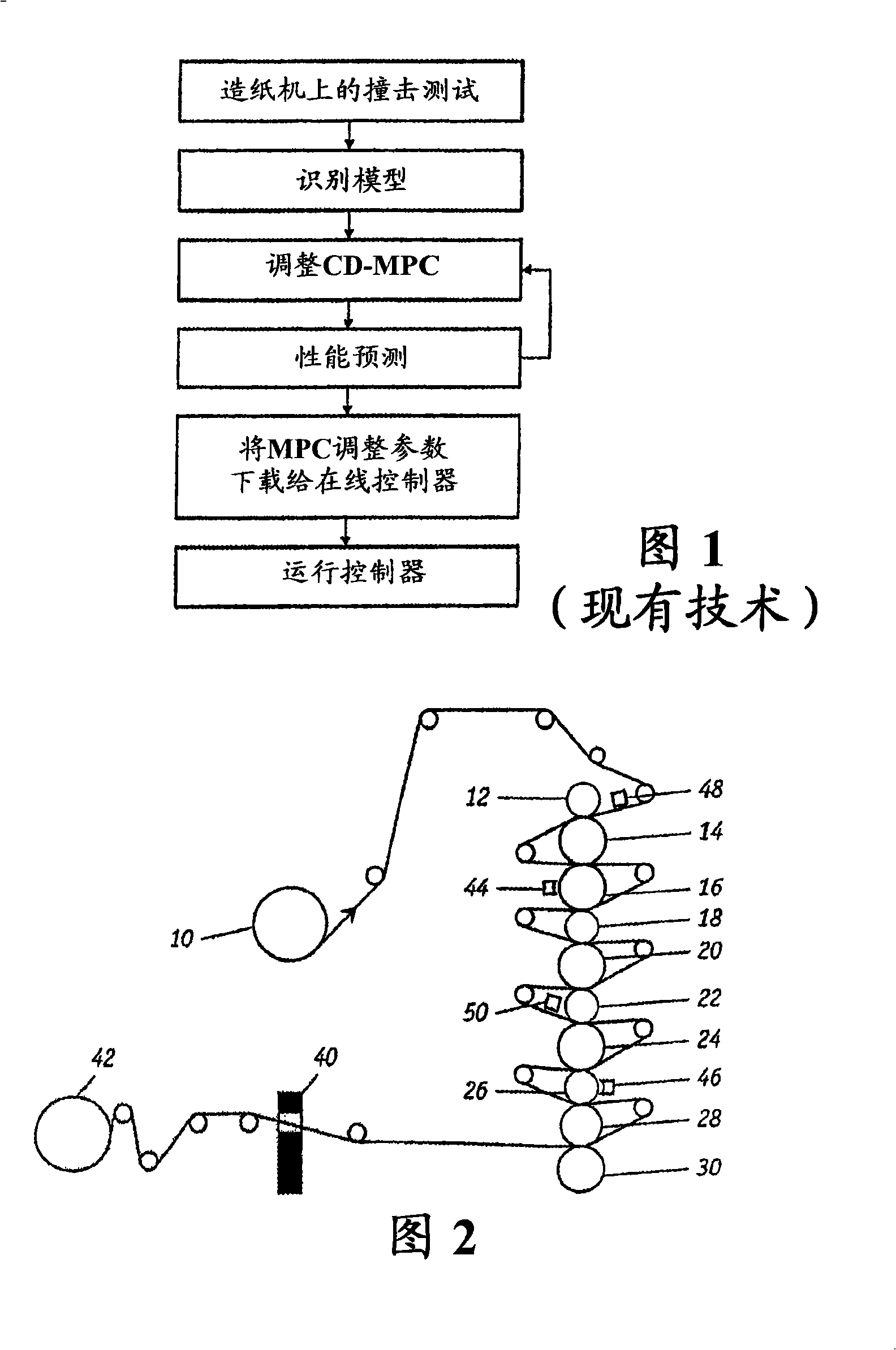

一种过程模型、空间分布的技术,应用在自适应控制、通用控制系统、控制/调节系统等方向,能够解决调整多元CD预测控制器困难、未指出控制器等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

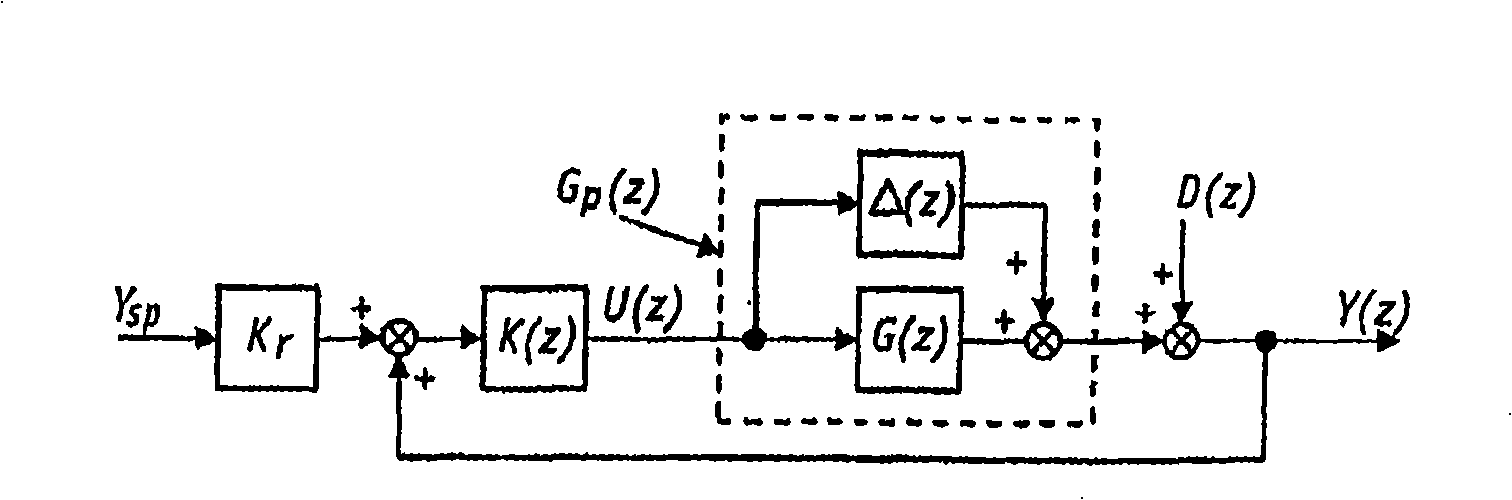

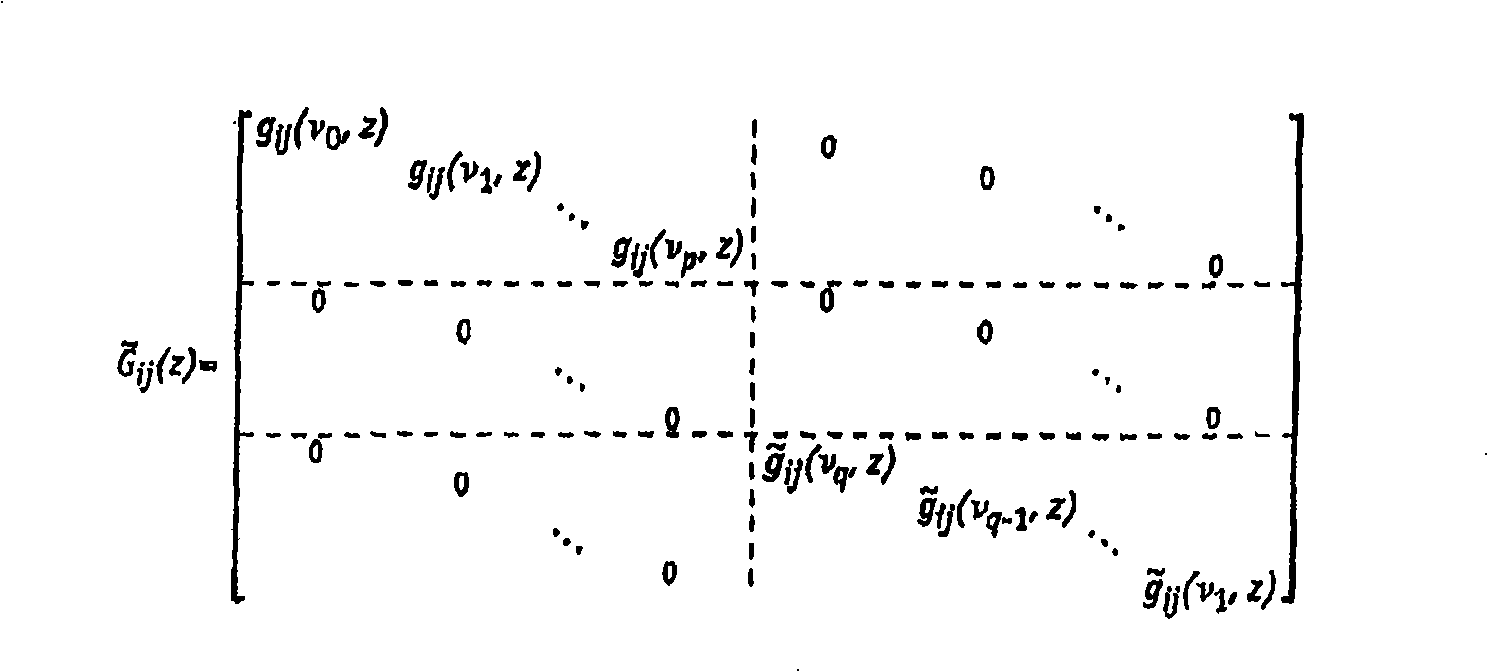

Method used

Image

Examples

Embodiment Construction

[0046] The self-tuning method of the present invention will be illustrated by implementing this technique in a large scale multivariate MPC controlling the high calendering process of a paper machine. High calendering is a common process in the paper industry. The high calendering process is either an on-machine continuous process or an off-machine batch process. It is used to improve the surface properties of the paper, such as smoothness and gloss (shine) which are critical for high quality printing papers. Paper can be uncoated, coated on one side or coated on both sides.

[0047] It should be appreciated that the techniques of the present invention are flexible enough to be applicable to any large-scale industrial multivariate transverse (CD) process that is controlled by a multivariate MPC. For example, in addition to off-machine and on-machine high-calendering processes, other paper machine processes can also be controlled by the multivariate MPC. Suitable paper machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com