High-dryness oil field steam-injection boiler and high-dryness steam production method

A steam injection boiler, high dryness technology, which is applied in earth-moving drilling, wellbore/well components, isolation devices, etc., can solve the problem that the steam dryness cannot meet the steam dryness standard, etc. The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0018] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

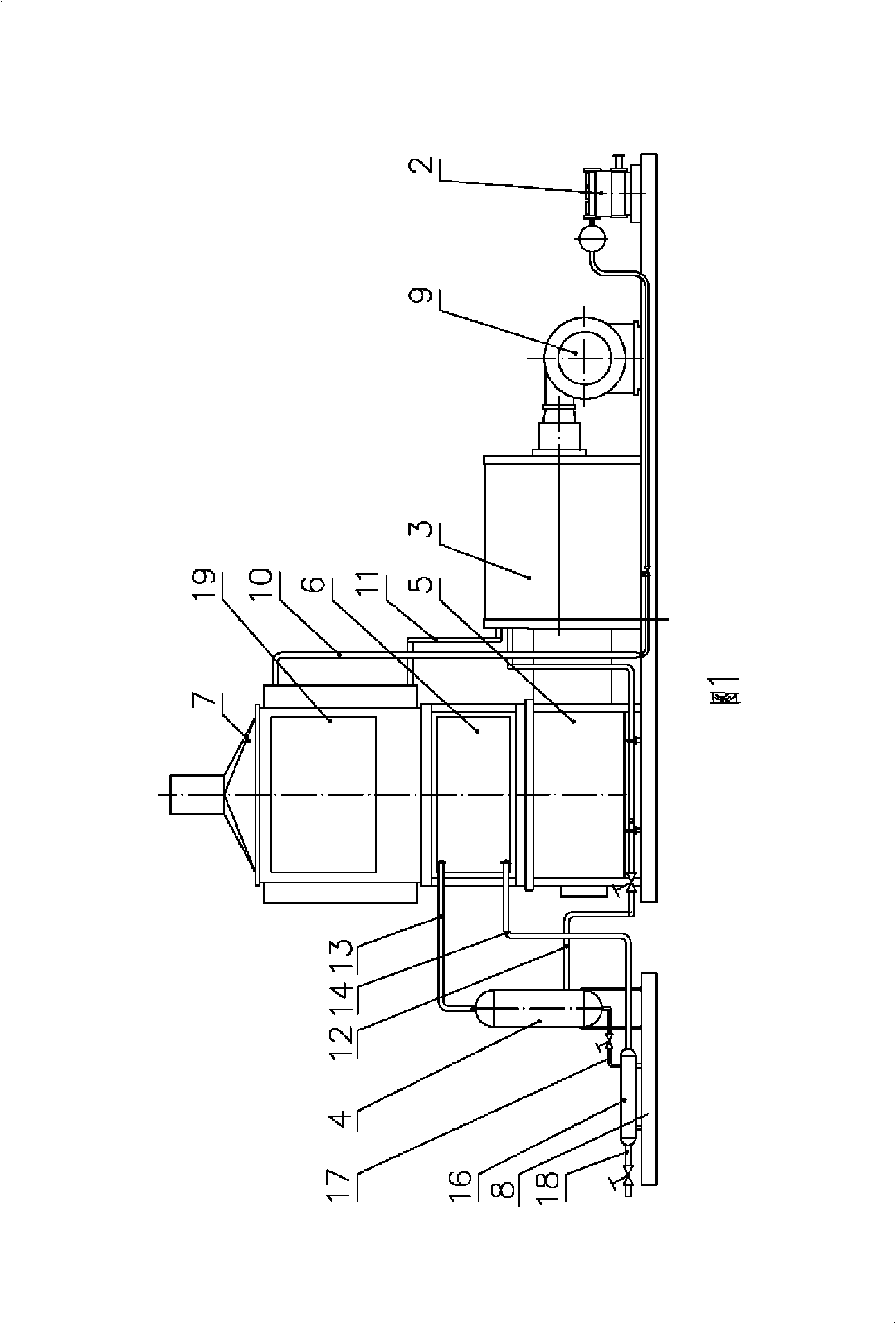

[0019] As shown in accompanying drawings 1 and 2, the high-quality oilfield steam injection boiler includes a radiation section 3, a convection section 19 and a transition section 5. The inlet of the radiation section 3 communicates with the outlet of the burner 9, and also includes a furnace body, a feed Water pump 2 and steam-water separator 4; Steam superheater 6 is fixedly installed in the furnace body between convection section 19 and transition section 5; The water outlet of the pipe 10 is connected with the water inlet at the upper end of the convection section 19; the inlet of the convection section outlet pipe 11 is connected with the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com