Building construction and construction method for autoclaved aerated concrete blocks

A technology of concrete block and autoclaved aeration, which is applied to building structures, building components, buildings, etc., can solve the problems of reducing the thermal performance of the wall, poor plastering layer powder, and poor building blocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

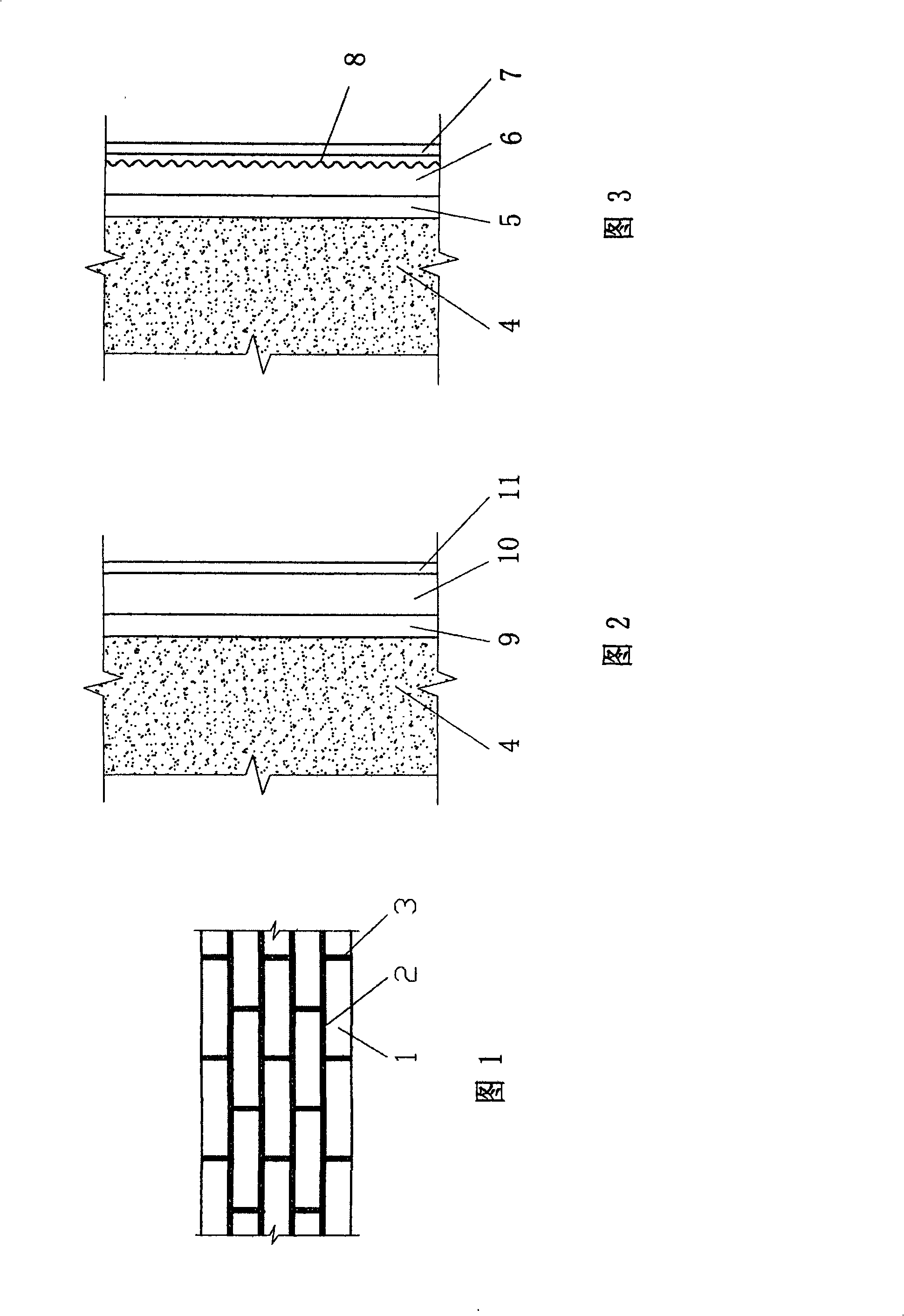

[0021] From Fig. 1-Fig. 3, it can be seen that the wall structure of autoclaved aerated concrete block of the present invention comprises: autoclaved aerated concrete block 1, block bonding layer 2, 3 (1,2,3 combined One is called the autoclaved aerated concrete block wall 4), the wall bonding layer 5,9, the leveling layer 6,10, the finish layer 7,11, and the hot-dip galvanized welded wire mesh 8.

[0022] It can be seen from Figure 1 that the mortar used in the block bonding layers 2 and 3 between the autoclaved aerated concrete block 1 and the autoclaved aerated concrete block 1 is adhesive mortar, and the horizontal and vertical mortar between the blocks 2, 3 The thickness is 2-9 mm.

[0023] As can be seen from Fig. 2, the block bonding layer 9 is applied on the inner wall surface of the autoclaved aerated concrete block wall 4, a leveling layer 10 is applied on the block bonding layer, and a finishing layer 11 is arranged on the leveling layer, wherein The mortar used fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com