Dust-separation zinc extraction method

A technology for blast furnace dust removal and raw materials, which is applied in the field of dust removal and dust treatment, can solve the problems of difficulty in handling, dust removal dust affects the environment, waste of resources, etc., and achieves the effect of improving the utilization rate of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The dedusting ash used in the present invention is mainly four kinds of blast furnace dedusting ash, power plant dedusting ash, blast furnace gas mud and anthracite.

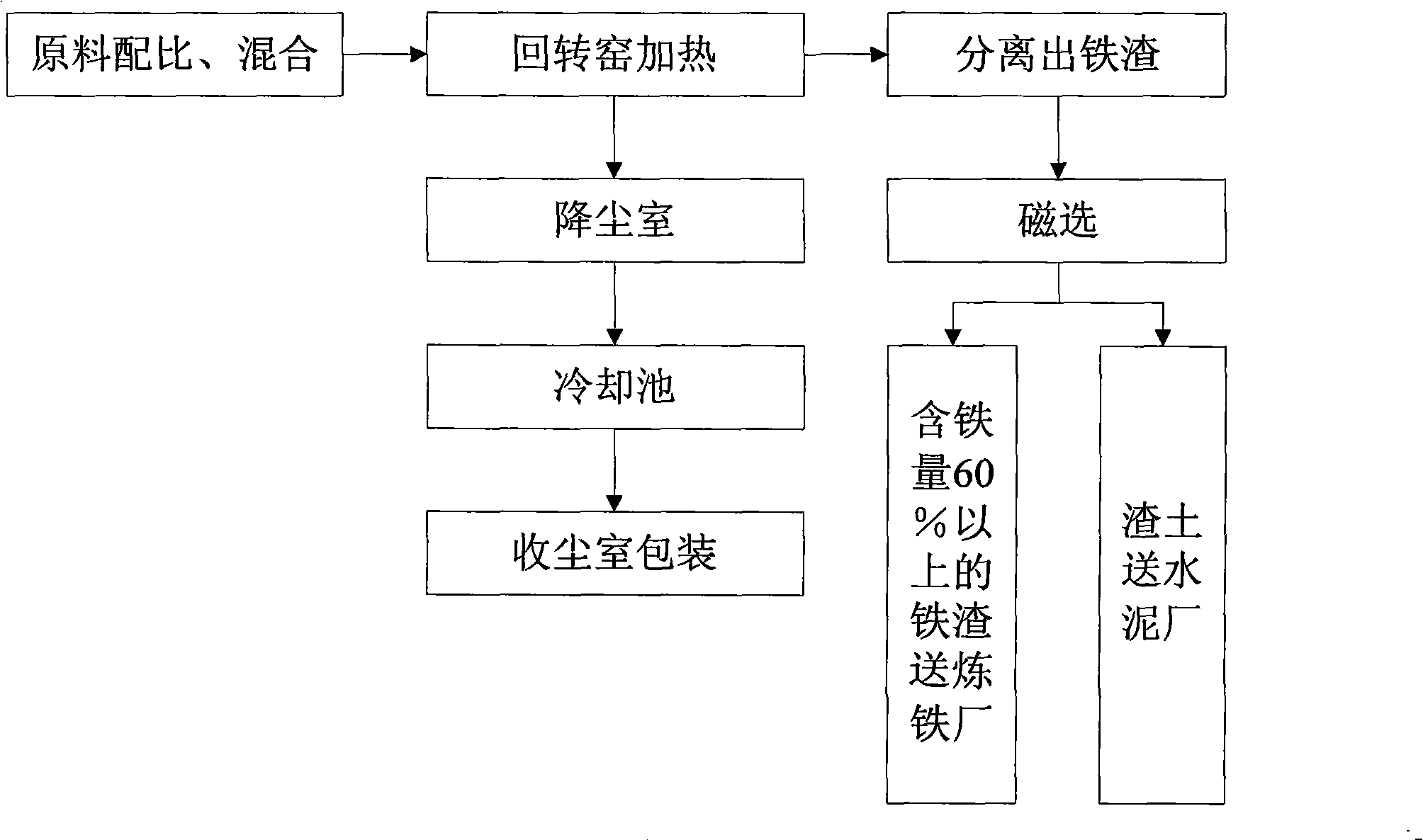

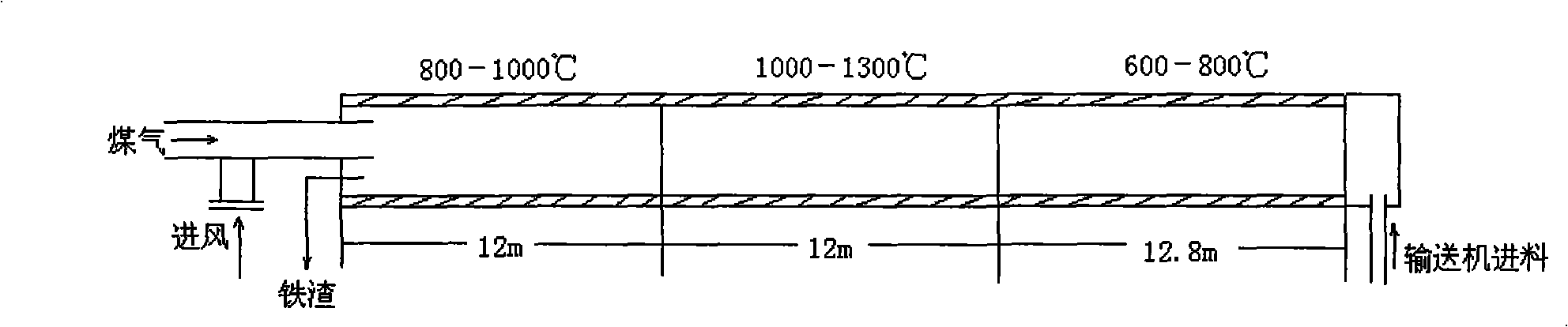

[0011] According to the weight ratio of 34% of blast furnace dust removal, 30% of power plant dust removal, 30% of blast furnace gas mud, and 6% of anthracite, the loader is used to mix and mix well, and then the materials are evenly sent to the rotary kiln for heating and refining by a conveyor, such as figure 2 , the rotary kiln body has a total length of 36.8 meters, an outer diameter of 2.5 meters, and a rotating speed of 2-3 rpm. A gas burner and a blower are installed at the kiln head (slag outlet), and the excess gas from the blast furnace or coke oven is used to enter The gas pipeline is fed into the burner and mixed with the wind from the blower, and the automatic ignition method of electronic ignition is used to ignite the gas and spray it into the kiln for combustion. In this way, the coal con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com