Bus-bar casing tube for high-voltage switch cabinet

A high-voltage switchgear and busbar bushing technology, applied in the direction of busbar/line layout, insulators, etc., can solve the problems of wasteful materials, time-consuming inventory, poor versatility, inconvenient installation or assembly, etc. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

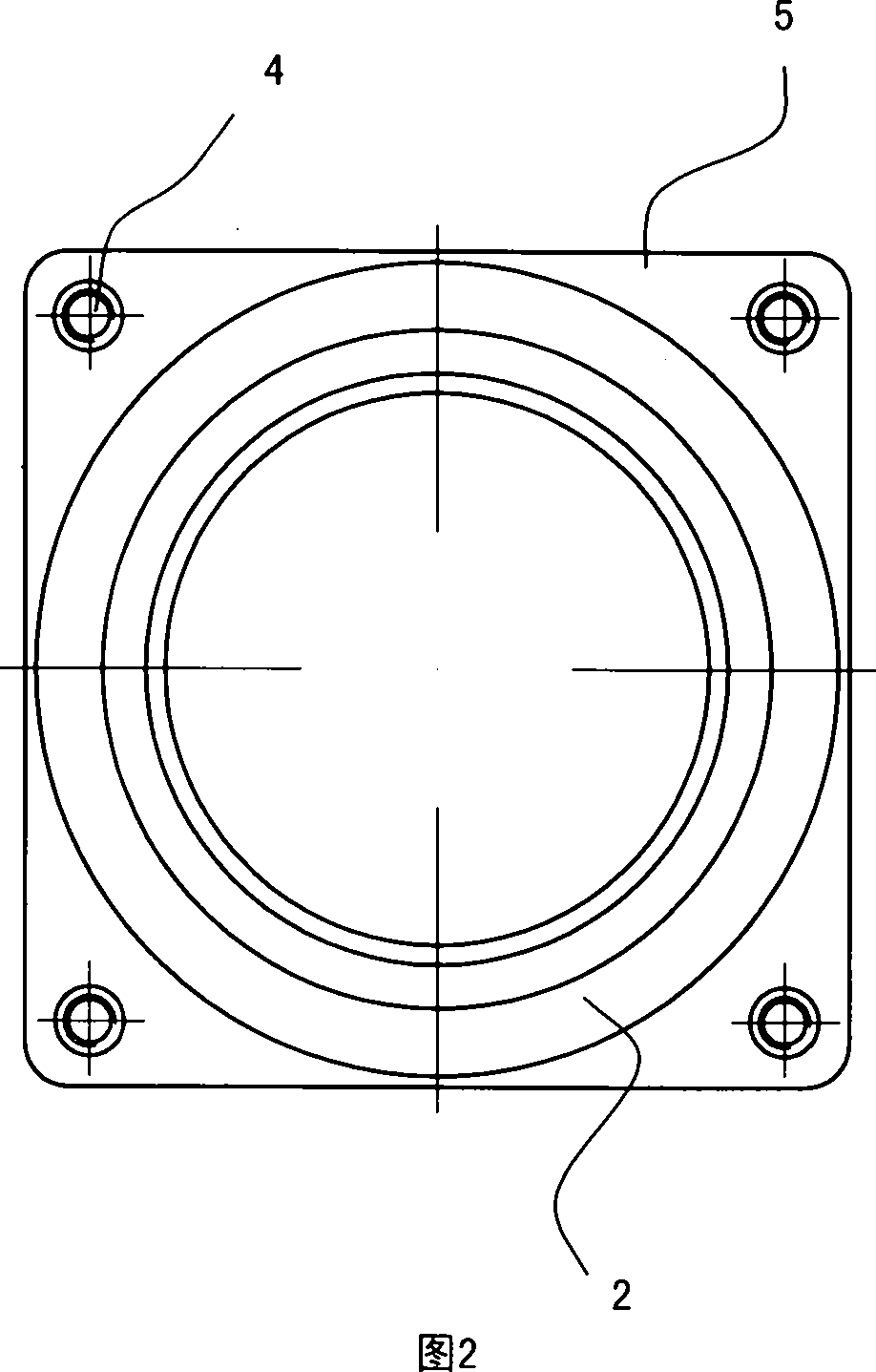

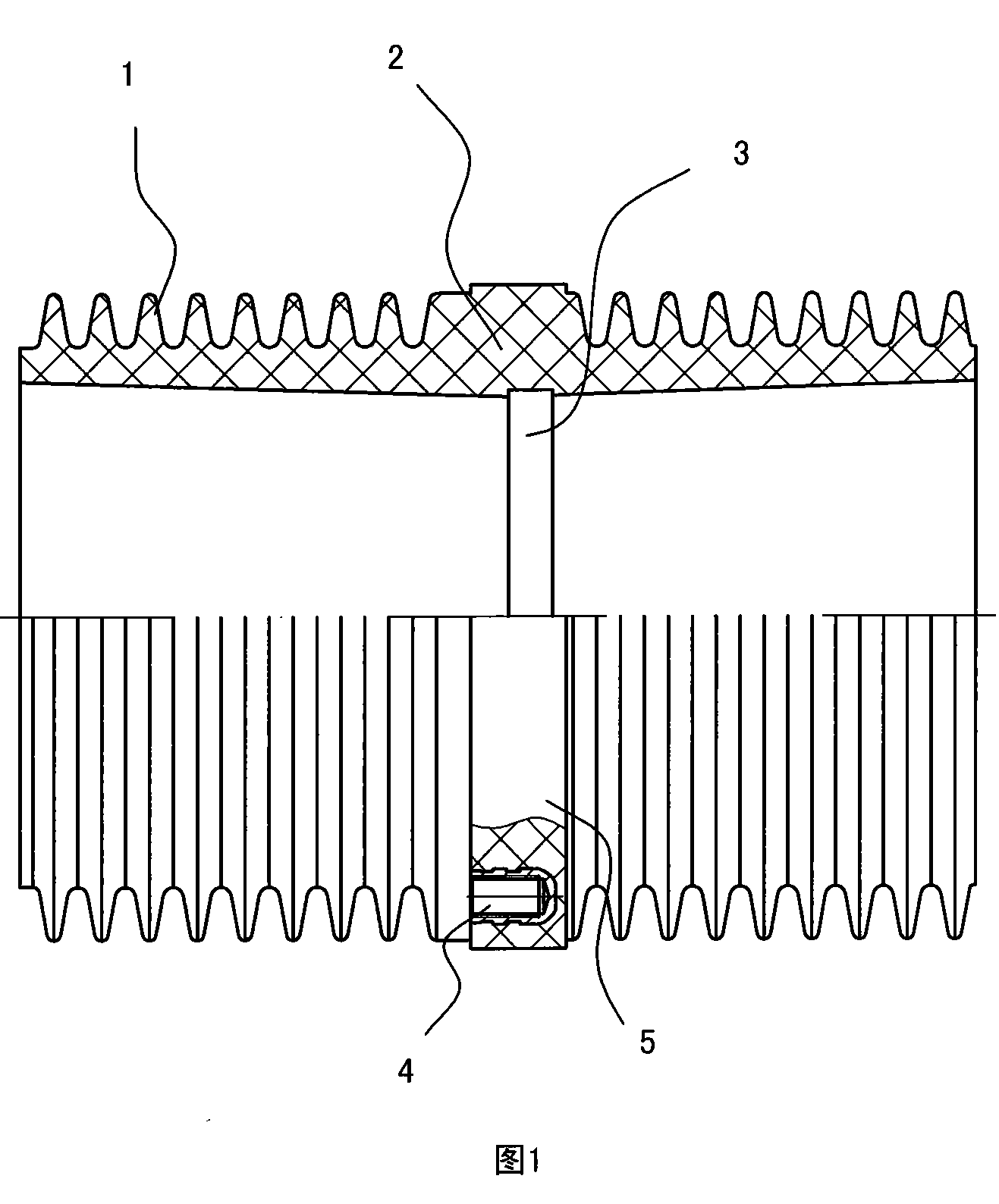

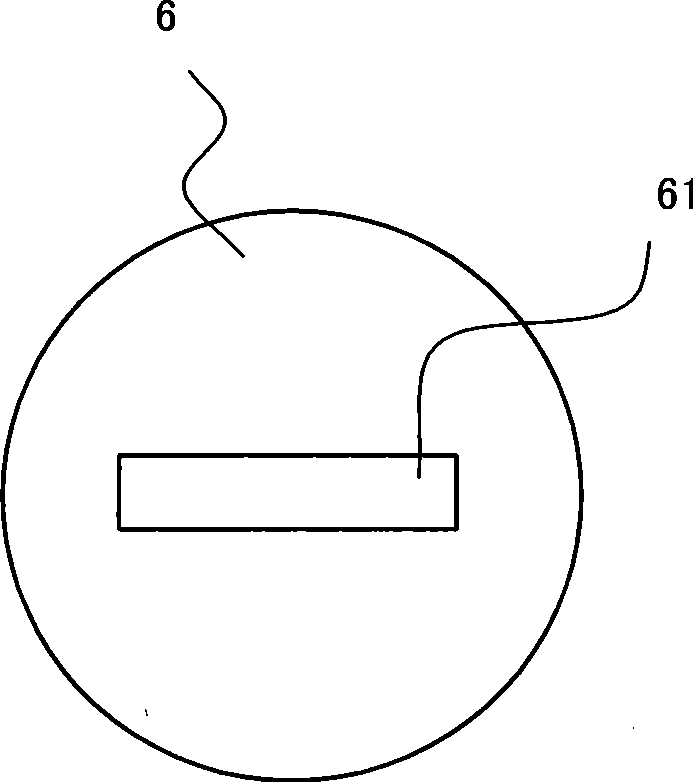

[0012] see figure 1 , and combined with figure 2 . The cross-sectional shape of the insulator 2 is circular, and a plurality of skirts 1 are arranged on its periphery to increase the creepage distance. A radial annular groove 3 is provided on the inner wall of the insulator 2 for receiving the busbar fixing plate 6. The width of the annular groove 3 should match the thickness of the busbar fixing plate 6, and generally a tight fit is better. The inner wall of the insulator 2 is separate from the busbar fixing plate 6, and the circular busbar fixing plate 6 made of silicone rubber material is embedded in the ring groove 3, and the busbar fixing plate 6 can be installed by extrusion.

[0013] The ring groove 3 is arranged in the axial middle of the inner wall of the insulator 2 , so that the metal busbars pass through the through hole 61 to form a balanced shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com