Contact system of circuit breaker

A contact system and circuit breaker technology, applied in the directions of circuit breaker contacts, circuit breaker parts, protection switch operation/release mechanisms, etc., can solve the problems of complex structure, spring failure, large resistance, etc., and achieve easy manufacturing and assembly. , Slow down the speed of the fall, the effect of small deformation of the spring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

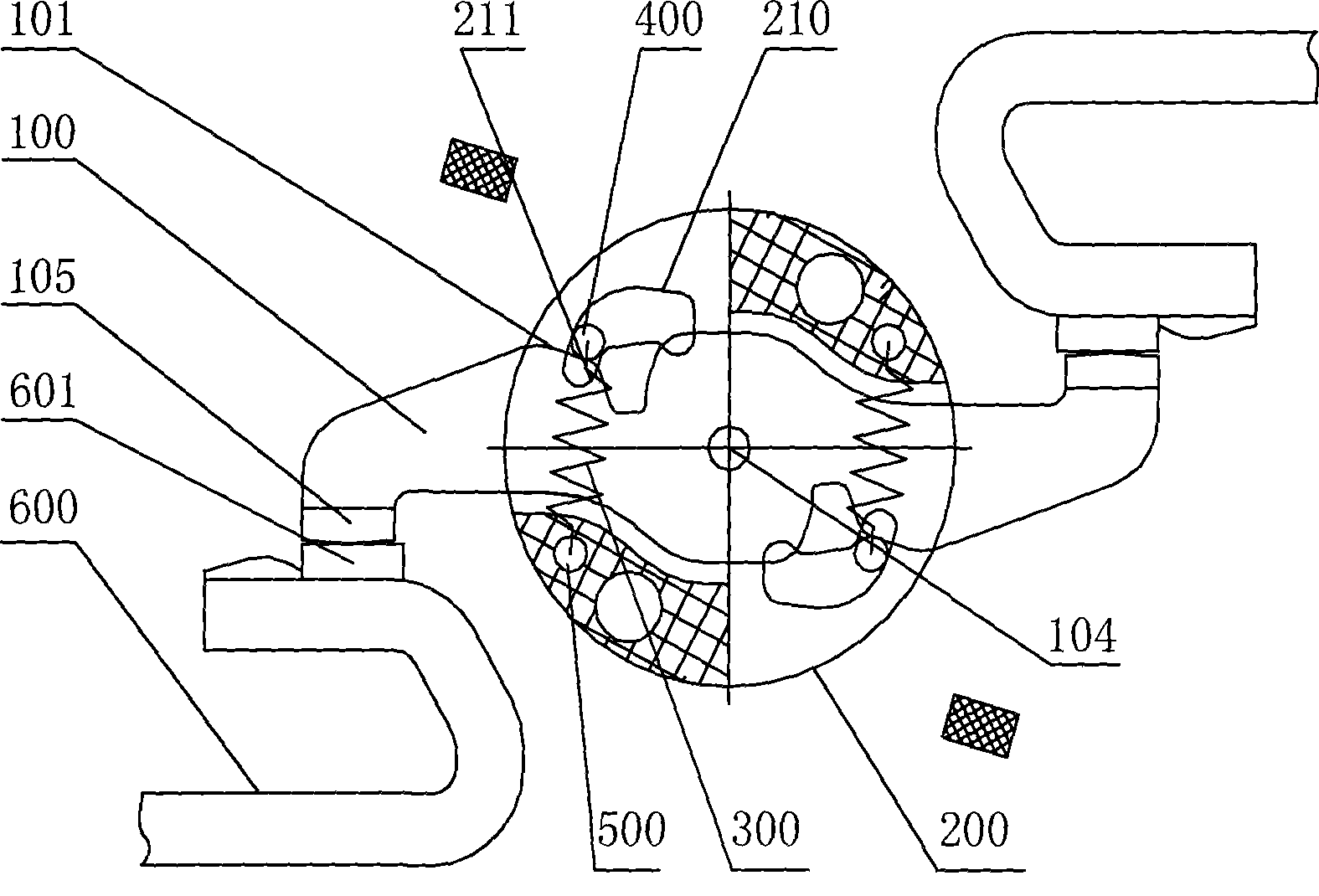

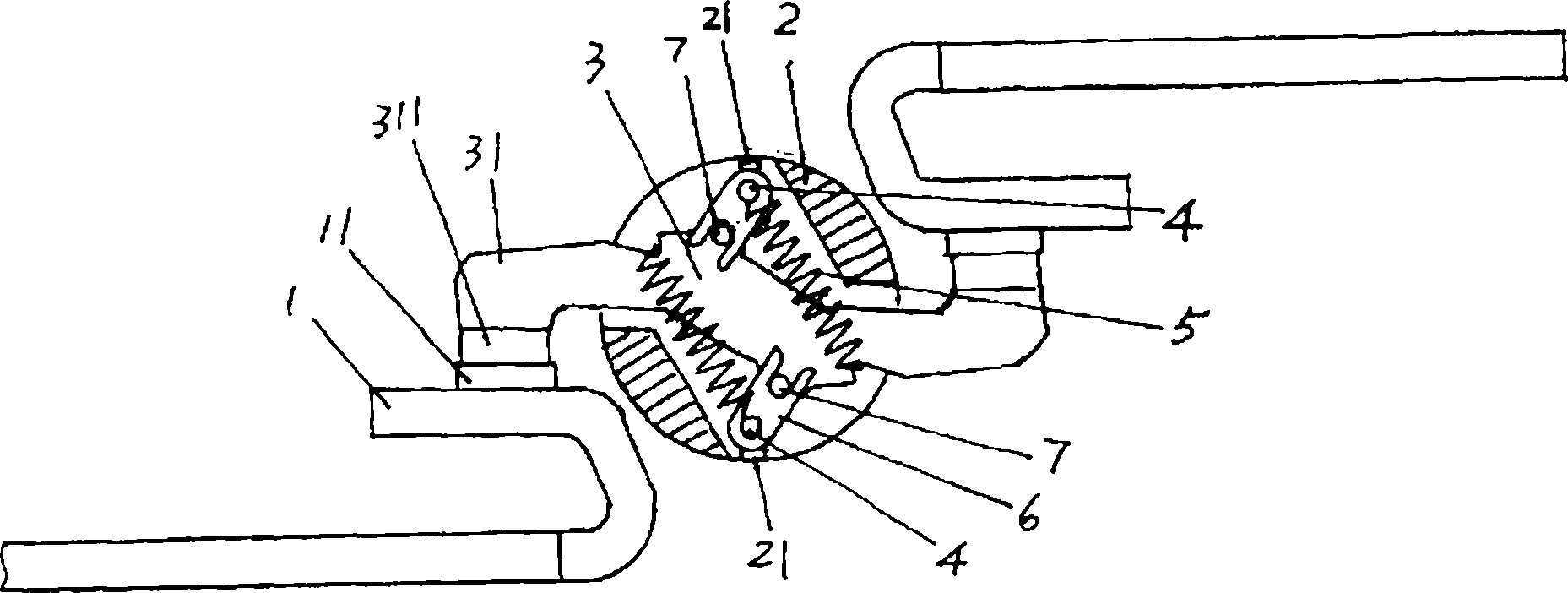

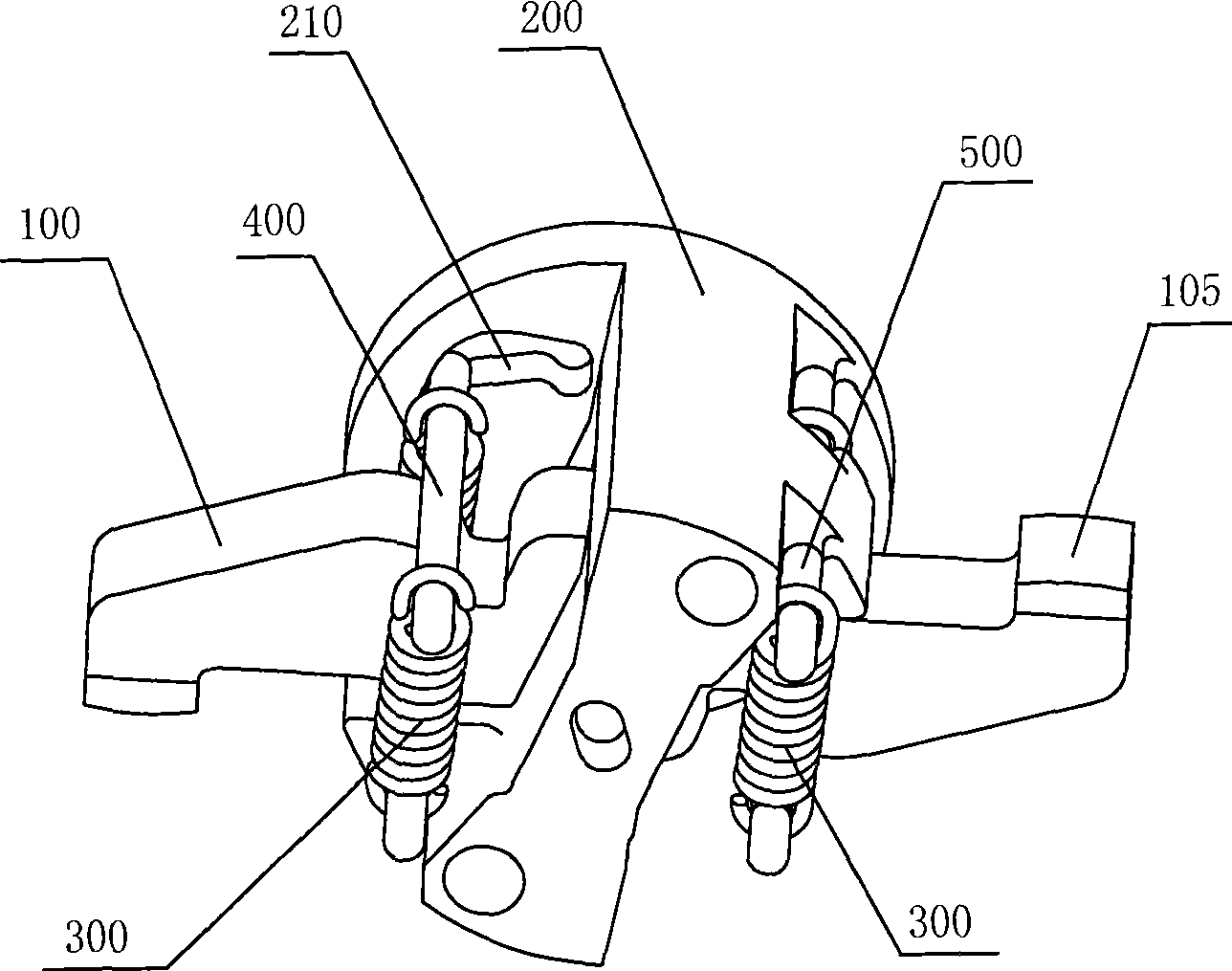

[0021] A circuit breaker double break point contact system of the present invention is shown in Fig. 2, Fig. 3 and Fig. 6. It includes a rotating shaft 200 and a pair of static contact rods 600 with curved parts. The static contact rods 600 are provided with static contacts Point 601 : a moving contact rod 100 passes through the rotating shaft 200 , and the moving contact rod 100 is provided with a central hole 104 , which can be connected to the rotating shaft 200 through a pivot and can rotate in the rotating shaft 200 . A cross-sectional shape of the rotating shaft 200 is shown in Figure 4, two pairs of sliding grooves 210 are symmetrically arranged at its two ends, and each sliding groove 210 includes a first concave portion 211, a second concave portion 212 and a A section of the smooth portion 213 between them is provided with a fixing pin hole 220 at a position opposite to the chute 210 . Both ends of the moving contact bar 100 are provided with a moving contact 105 whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com