Modified type unidirectional gravity force hot pipe

A gravity heat pipe, an improved technology, applied in indirect heat exchangers, lighting and heating equipment, etc., to achieve the effects of simple structure, prevention of reverse transfer, and strict unidirectional thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

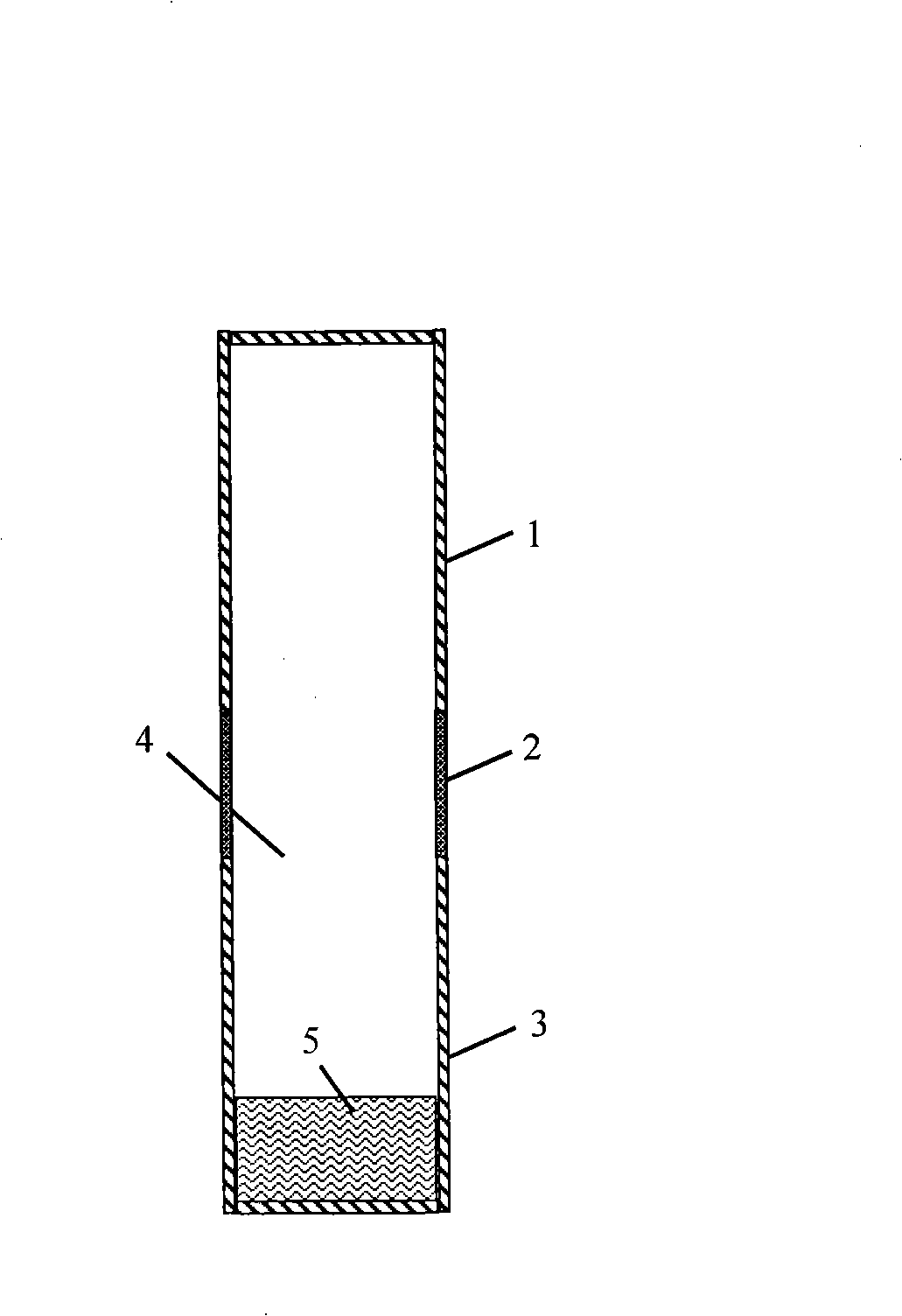

[0009] In the figure, the gravity heat pipe has a sealed chamber (4), and an appropriate amount of heat pipe working medium (5) is sealed in the sealed chamber (4). The pipe body is divided into a condensation section (1) and an evaporation section along the length direction of the pipe body. (3) and the adiabatic section (2) between the two, the condensation section (1) is located at the top of the gravity heat pipe, and the evaporation section (3) is located at the bottom of the gravity heat pipe. The casings of the condensation section (1) and the evaporation section (3) are made of materials with high thermal conductivity, and the heat insulation section (2) is made of a heat insulation material different from that of the condensation section (1) and the evaporation section (3). When the temperature of the evaporating section (3) is higher than that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com