Container integrated modularizing pollutant handling arrangement

A pollutant treatment and integrated module technology, applied in anaerobic digestion treatment, waste fuel, etc., can solve the problems of high cost, difficult disassembly and cleaning, and high cost of anaerobic treatment system, and achieve simple, easy and simplified daily operation and maintenance. Design and manufacturing procedures, cost and cycle reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

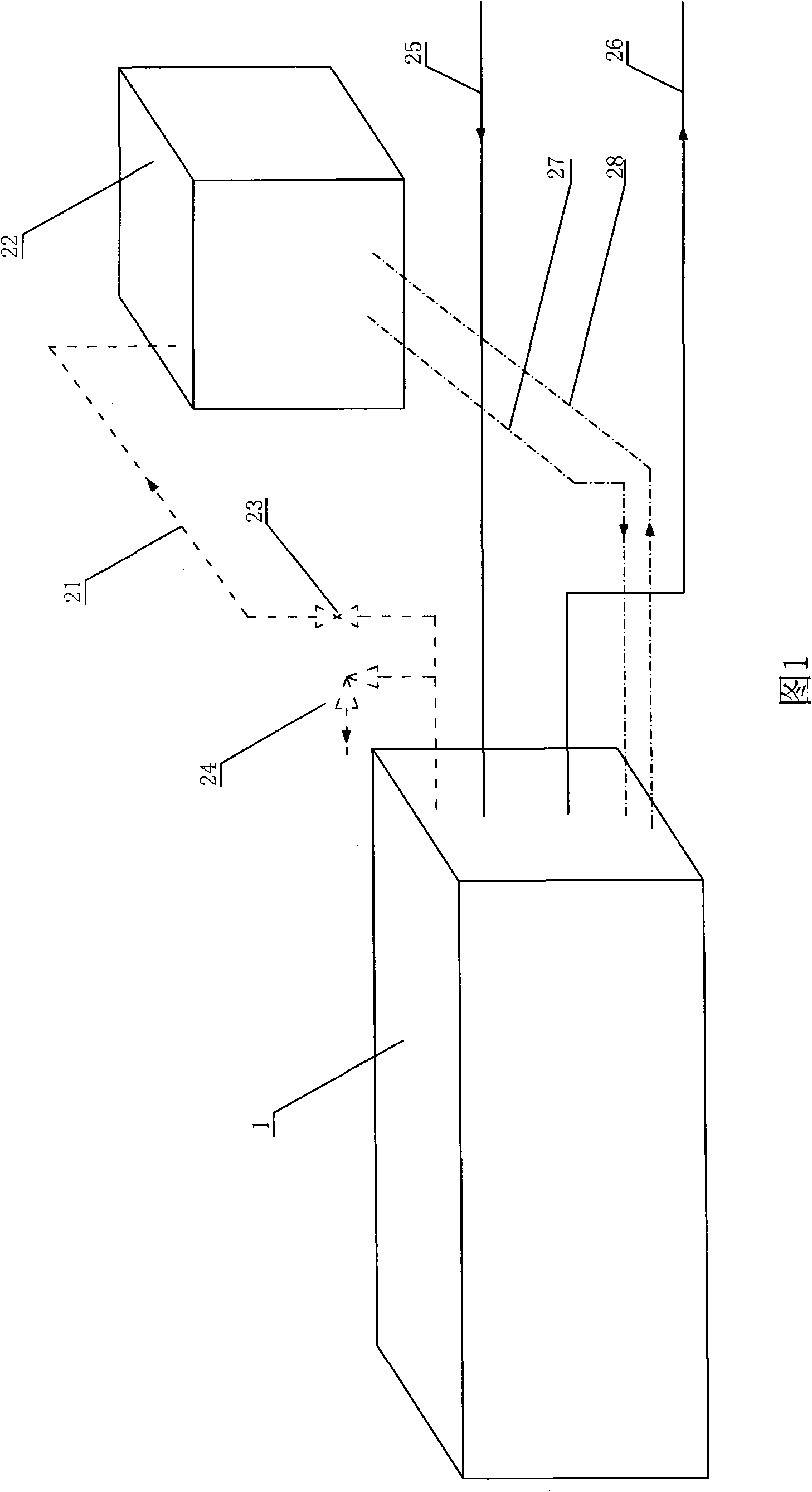

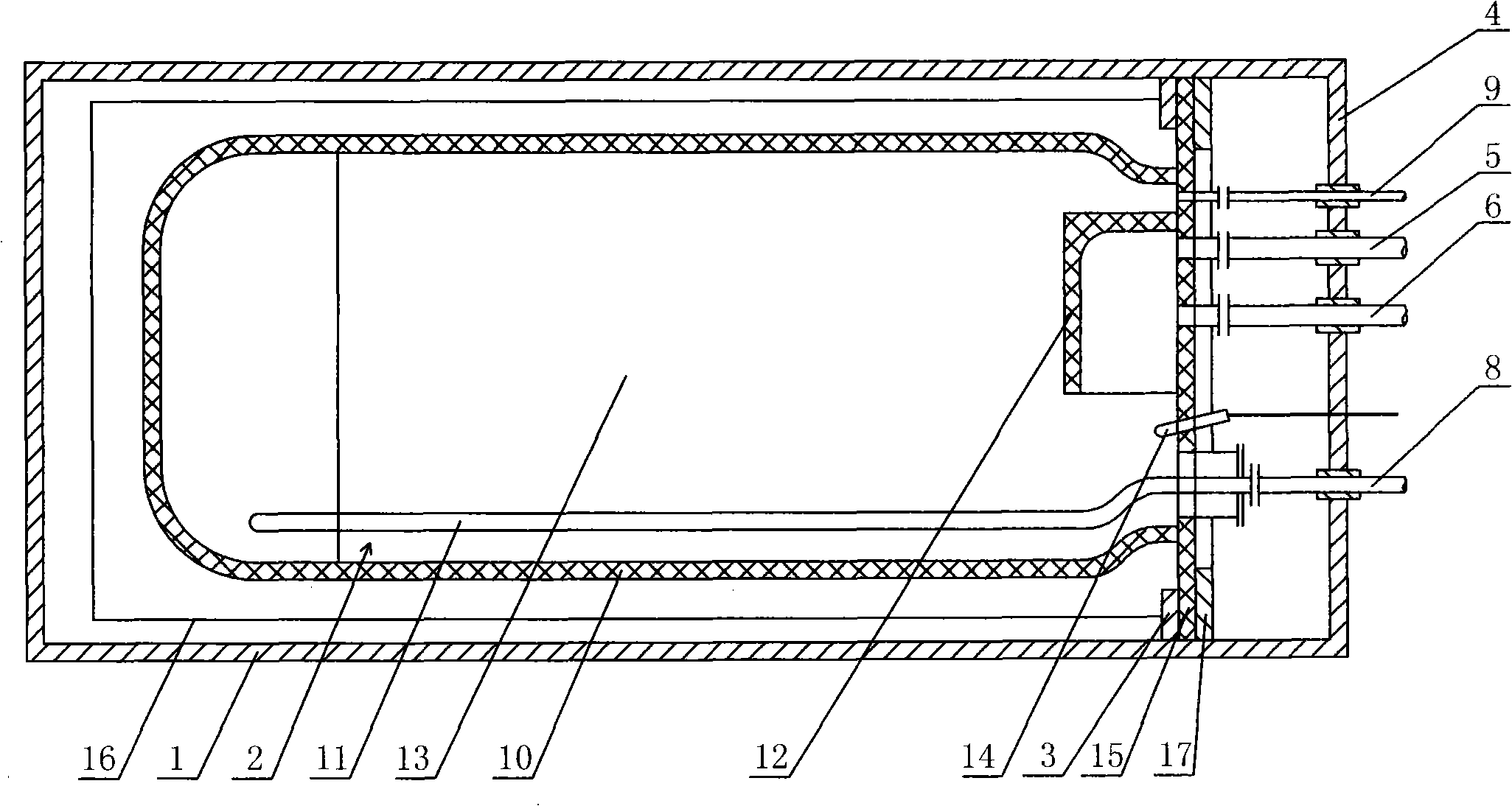

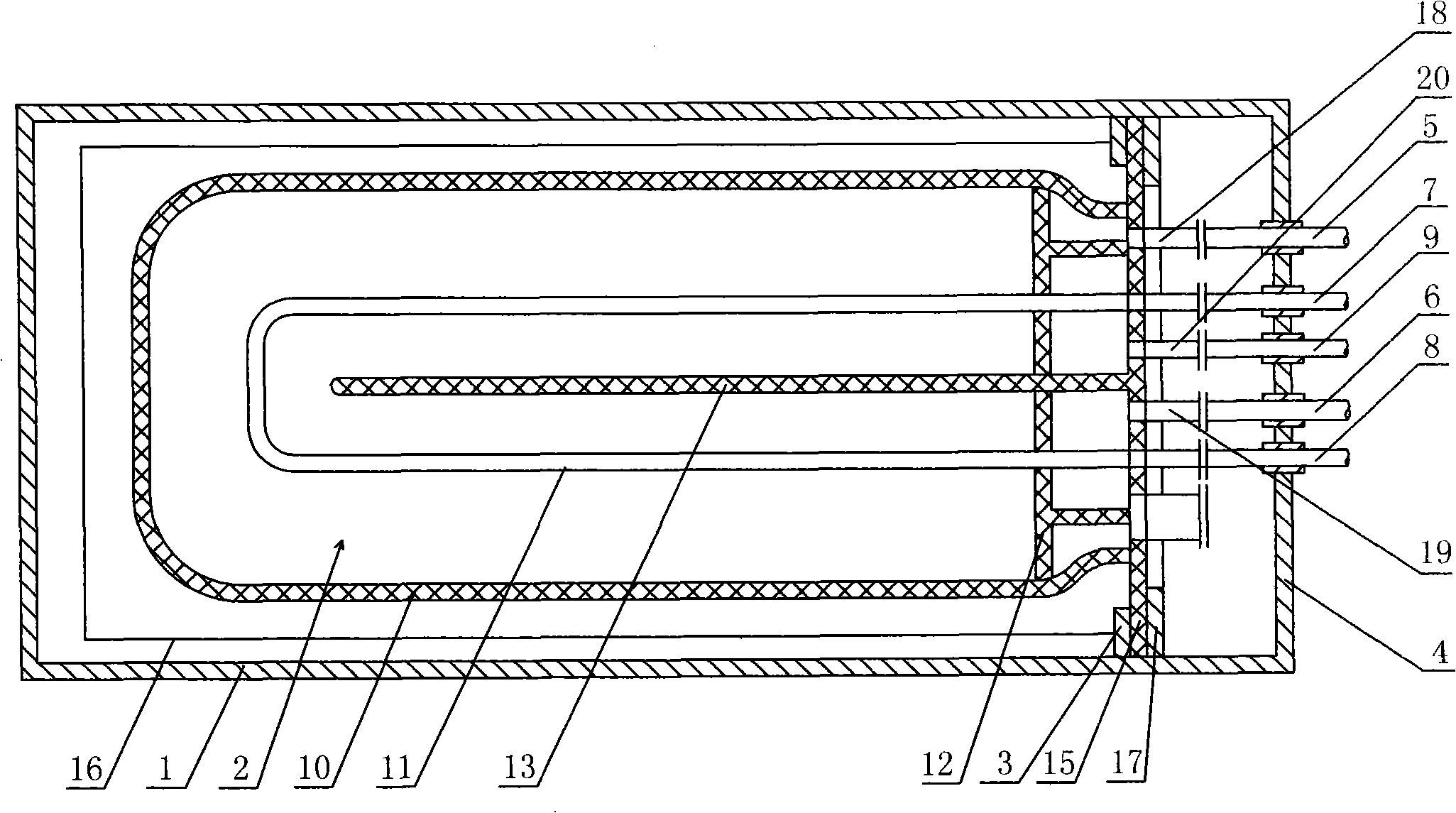

[0032] The container-integrated modular pollutant treatment device is mainly composed of an outer casing 1 and a reactor 2, and the reactor 2 is an anaerobic fermentation reactor.

[0033] The outer shell 1 is a standard container with a length of 6-12m, a width of 1.5-2m, and a height of 1.5-2m. There are fresh material inlet pipe 5, product outlet pipe 6, hot water input pipe 7, return water outlet pipe 8 and methane output pipe 9. The inner wall of the container 1 is lined with a benzene board insulation layer 16 .

[0034] The anaerobic fermentation reactor 2 is arranged in the container 1 . The anaerobic reactor 2 includes a reactor shell 10 , a heating coil 11 , a transverse partition 12 , a vertical partition 13 and a thermocouple 14 . The coiled pipe 11 is a U-shaped pipe.

[0035] The reactor shell 10 is made of rubber, and its volume is adapted to the inner space of the container 1 . There is a skirt 15 at the front of the reactor shell 10, one end of the transve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com