Recovery processing method of waste plastics film shopping bag and electro-thermal regeneration boiler thereof

A plastic film recycling technology, which is applied to the recycling and recycling of waste plastic film shopping bags and ultra-thin plastic shopping bags, and in the field of electric heating regenerative pots, can solve the problems of inadequate recycling and processing, achieve small investment, improve heating efficiency, The effect of low running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

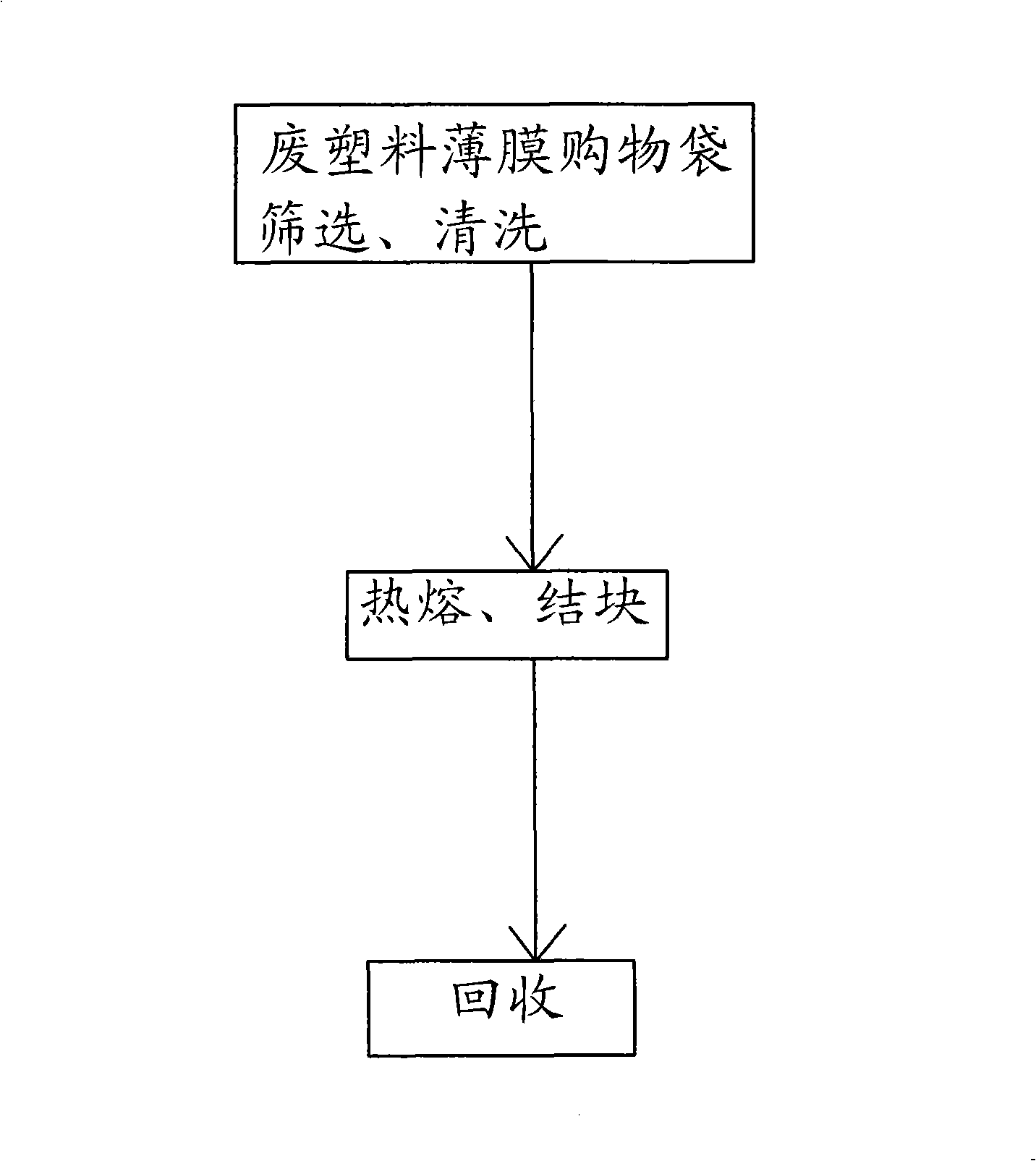

[0024] Such as figure 1 As shown, the recycling method of the waste plastic film shopping bag, the method comprises the following steps: waste plastic film shopping bag screening, cleaning: the waste plastic film shopping bag is screened out from domestic garbage, and those with dirt attached will be cleaned. dry.

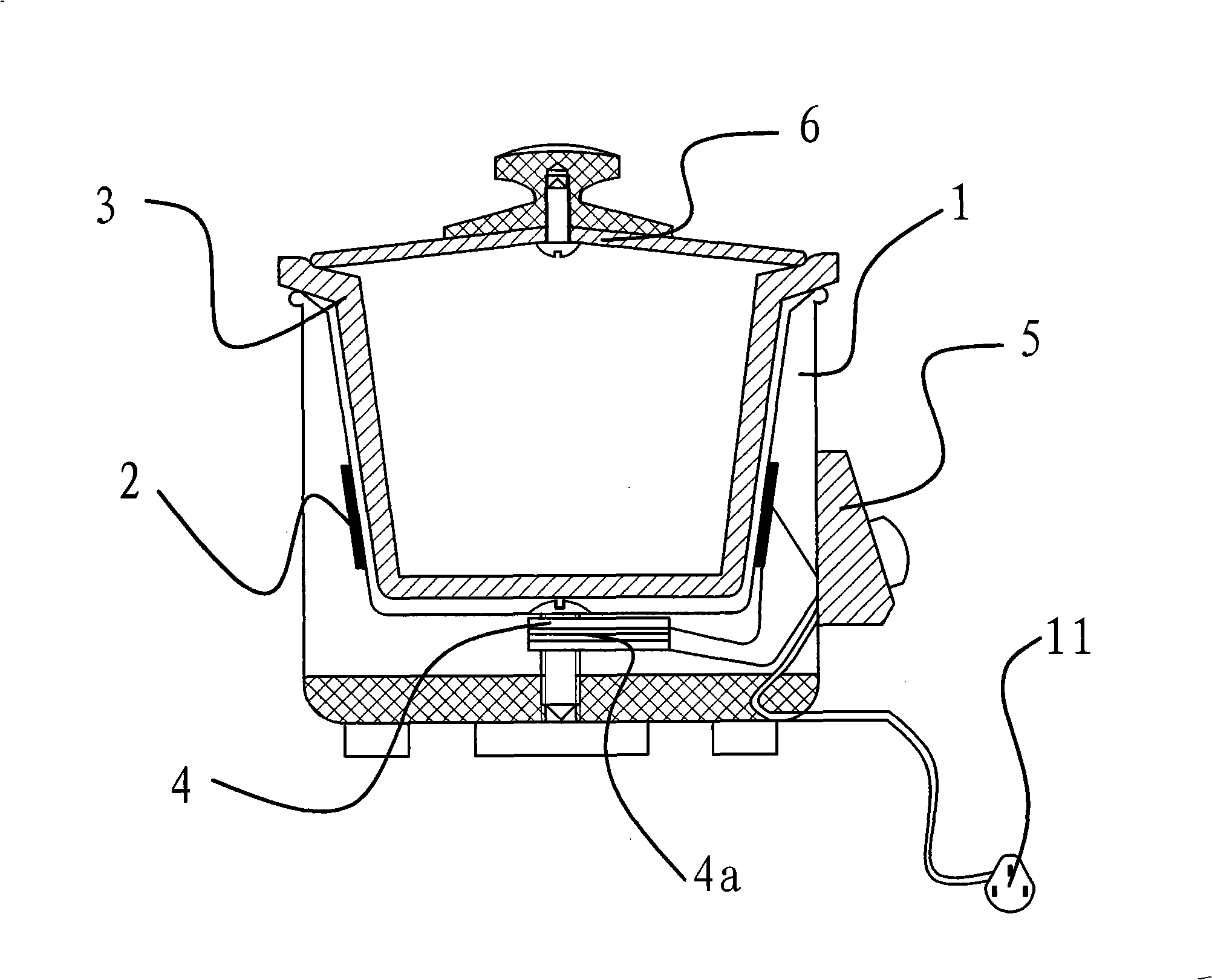

[0025] Put the above-mentioned waste plastic shopping bags into balls into the melting tank 3 of the electric heating regeneration pot, and carry out thermal fusion and agglomeration in the melting pot 3 of the electric heating regeneration pot, first insert the power plug 11 of the electric heating regeneration pot into the power socket, and turn on The circuit switch 5 makes the heating plate 2 heat the crucible 3 . Here the heating temperature is automatically reached between 150°C and 200°C. In this embodiment, when the actual temperature automatically reaches 180°C, it starts to be melted and agglomerated. After 5 minutes, the waste plastic shopping bags to b...

Embodiment 2

[0030] The heating temperature is 150° C., and the heating time is 10 minutes. Other technological processes are the same as those in Example 1, and will not be repeated here.

Embodiment 3

[0032] The heating temperature is 200° C., and the heating time is 1 minute. Other technological processes are the same as those in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com