Processor, test tray transfer method and package chip manufacture method

A technology for testing trays and installing chips, which is applied in the field of processors and can solve problems such as control operation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings.

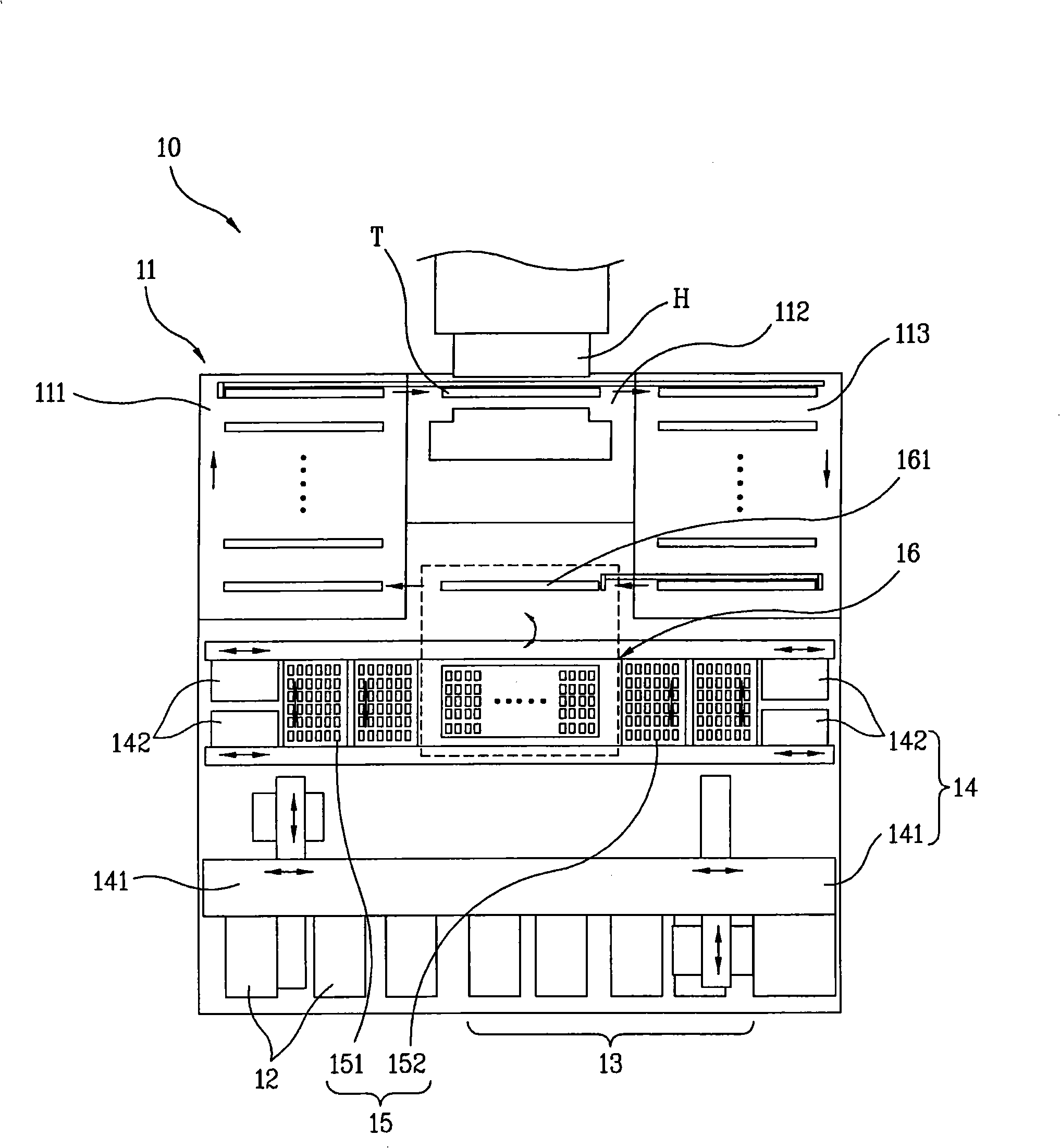

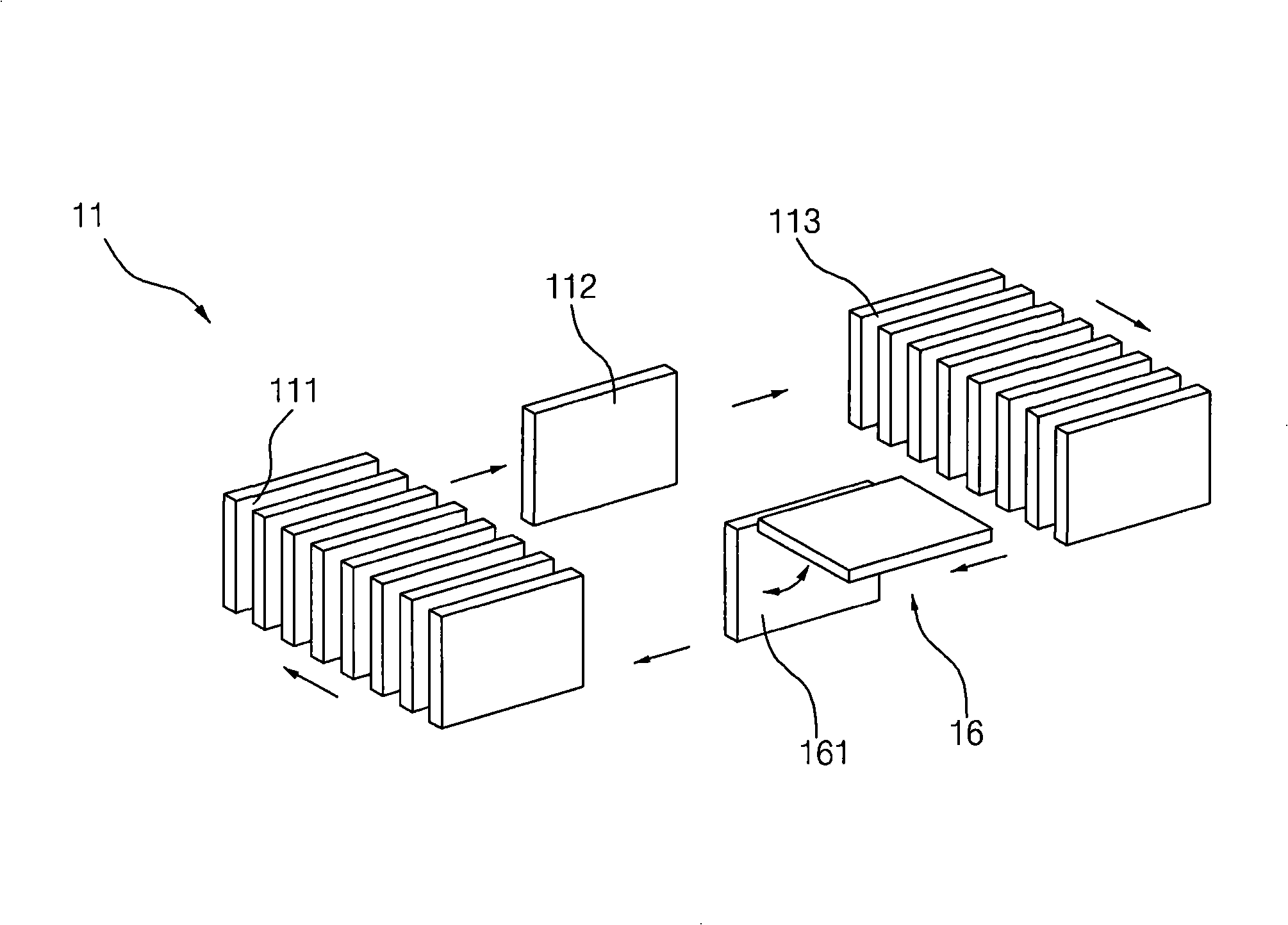

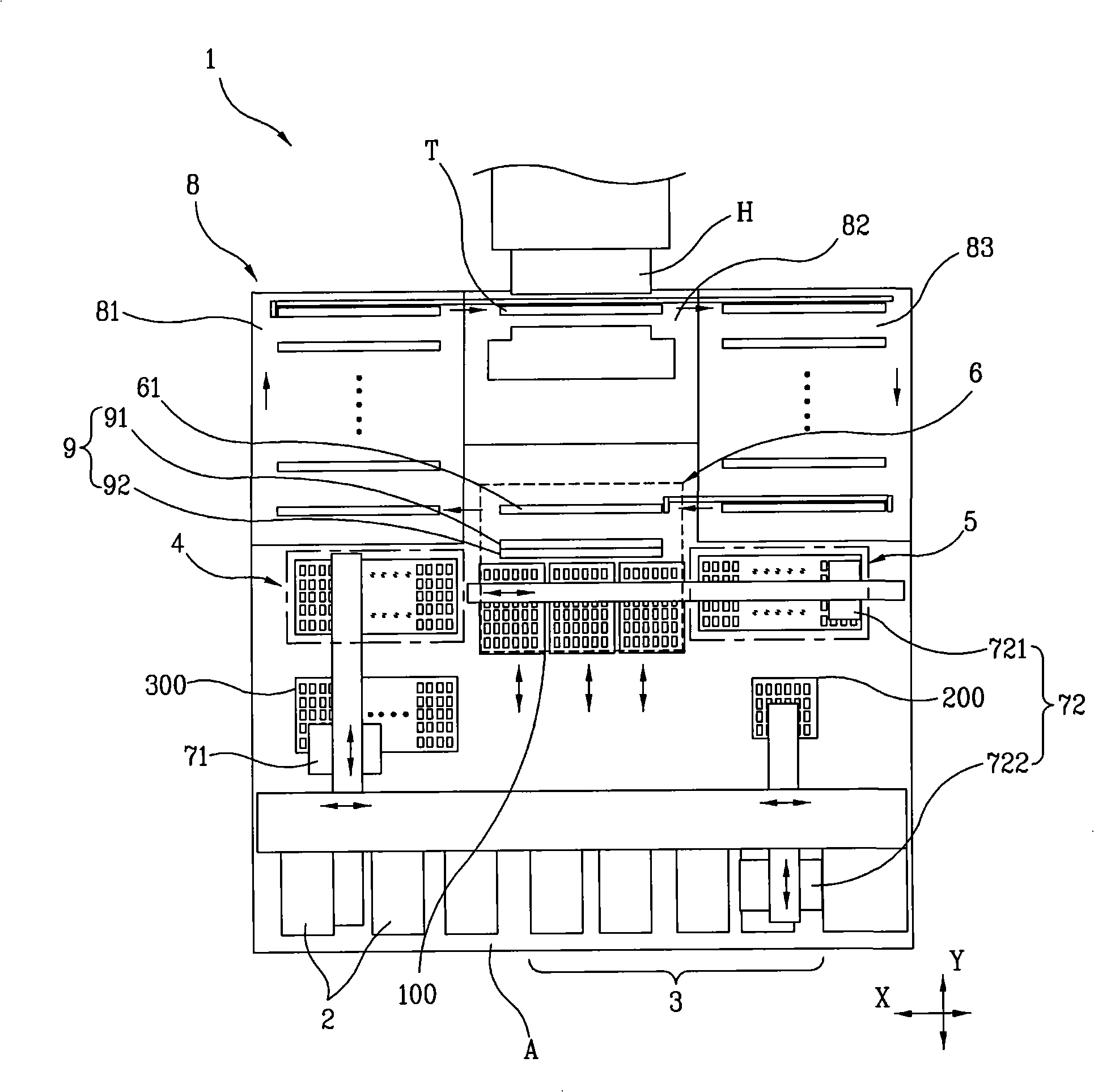

[0041] image 3 It is a plan view of the structure of the processor used in the present invention. Figure 4 is a schematic diagram of the test tray path between the loading unit and the unloading unit in the handler. Figure 5 is a schematic diagram of the path of the test tray inside the chamber of the first embodiment of the present invention. Image 6 is a schematic diagram of the path of the test tray inside the chamber of the second embodiment of the present invention. Figure 7 is a plan view of the handler illustrating the path along which the test tray is moved from the unloading position to the loading position.

[0042] like image 3 As shown, the handler 1 of the present invention includes a loading stacker 2, an unloading stacker 3, a loading unit 4, an unloading unit 5, a rotating unit 6, a picker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com